71-50-803 Exchange of Connector to Boost Pressure Actuator (BPA)

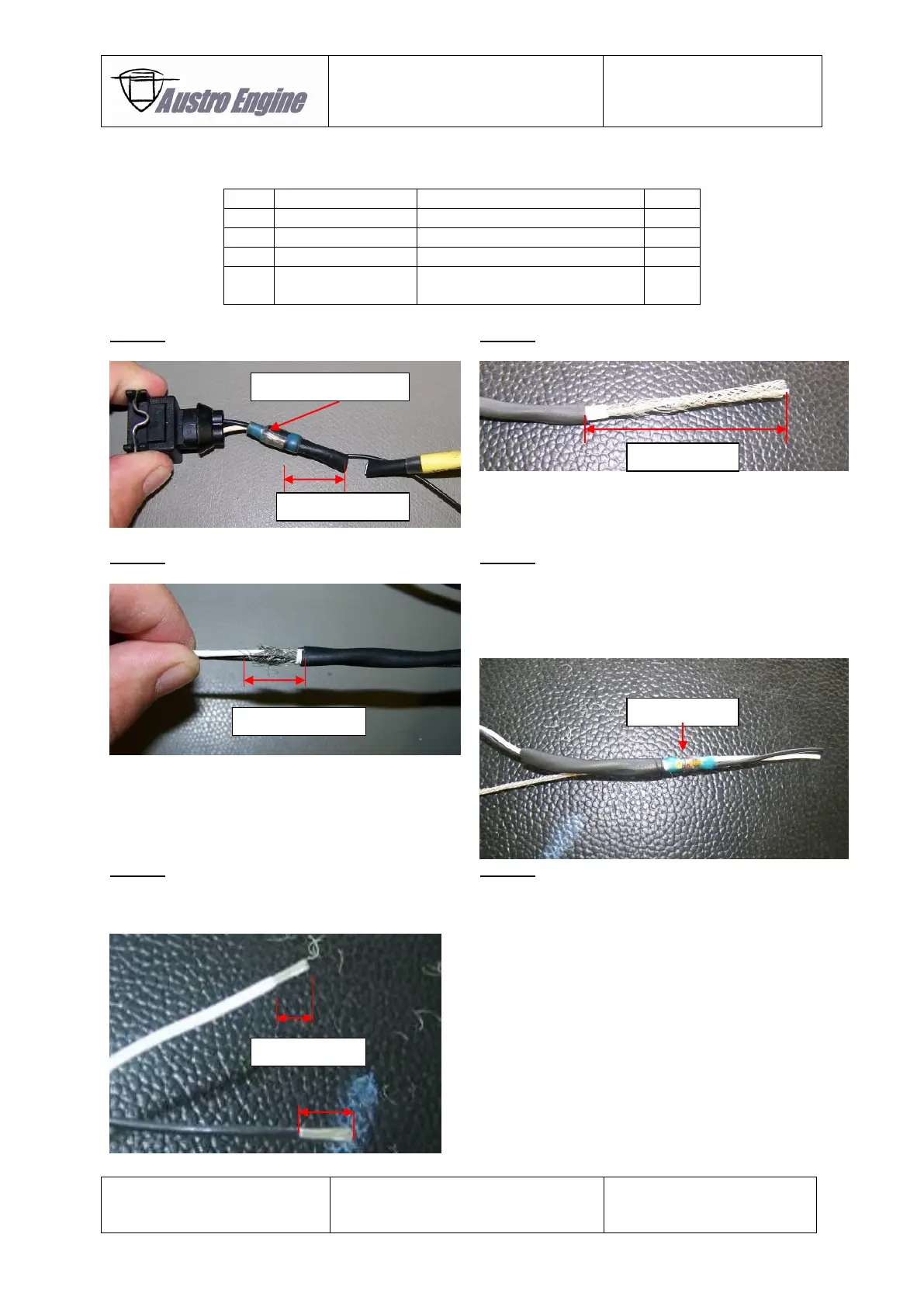

Step 1:

Cut off the old solder sleeve of the BPA branch.

Remove the black and white cable insulation.

Remove the shielding as shown below.

Put the solder sleeve over the wiring harness cable

and place it above the shielding.

Heat the solder sleeve (300°C – 350°C) with a hot air

gun until the solder sleeve is connected with the

cable and the shielding

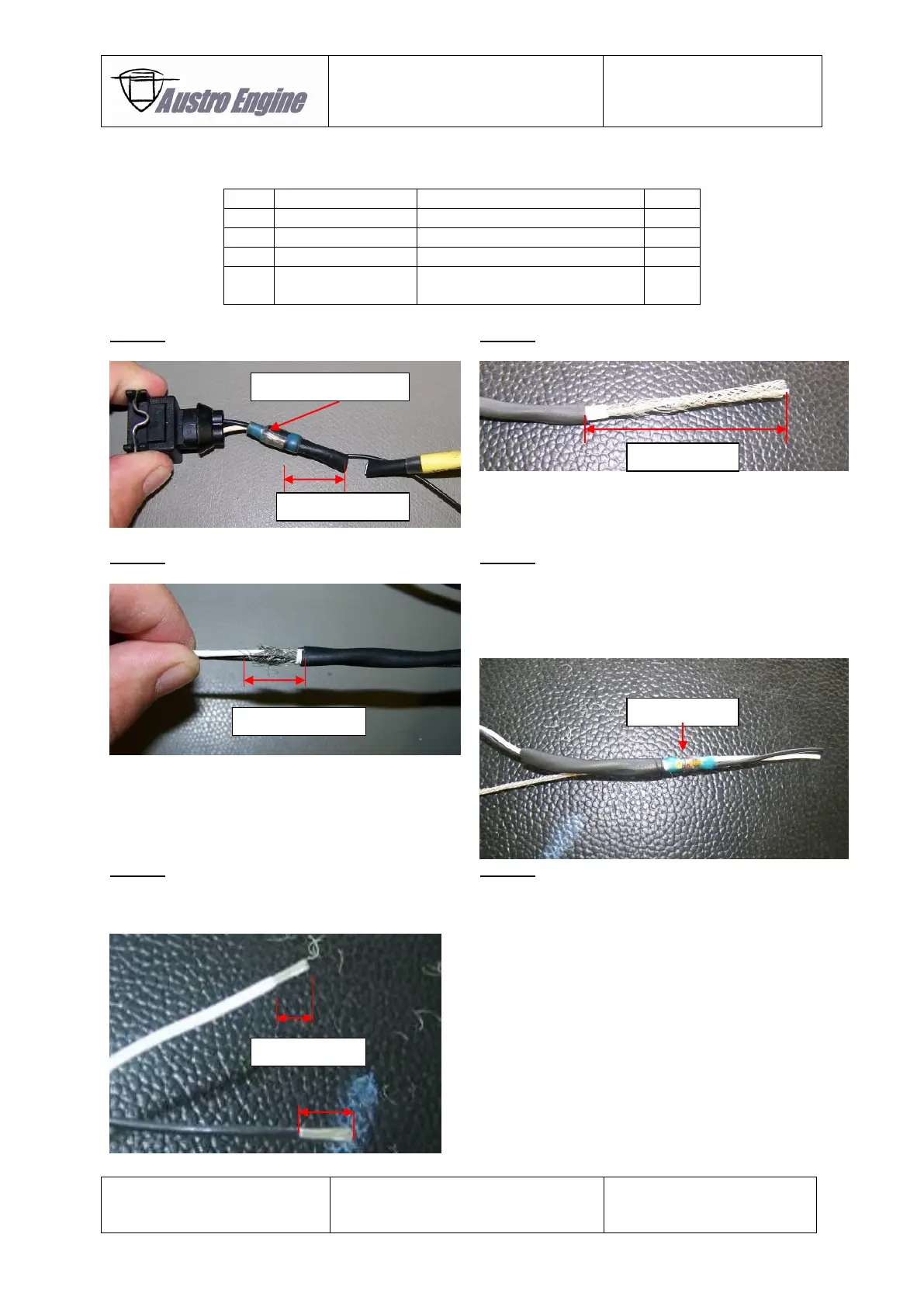

Step 5:

Remove the isolation of single wire on the end of

the engine wiring harness and the cable of the

repair kit as shown below.

The inline crimp consists of the splice crimp and the

isolation sleeve. Put the isolation sleeve of the inline

crimp over the single wire of engine harness.

Place the splice crimp at the end of the single wires

of the repair kit cable E4A-90-R17-000.

See also picture of step 6 of chapter 71-50-802.

Loading...

Loading...