01-10-10 Intake/Exhaust System Description

General:

For operation the engine has to be supplied by the intake system with compressed air at manifold

pressures up to 2660 mbar (38,57 psi), which varies with altitude and power setting. The increased

manifold pressure is accomplished with an exhaust driven turbo charger. After the turbocharger, the

air passes through the intercooler, through the engine to the turbine side of the turbocharger before

exhausting to the atmosphere.

The intake air is cleaned by an air filter and then compressed by the turbo charger. During

compression the intake air gets hot. An intercooler between turbo charger and engine is provided to

cool the intake air down thus the desired engine performance can be obtained.

At the intake manifold the intake air temperature and intake air pressure are measured. For the

temperature and pressure readings there are two sensors for each value installed. To provide the

intake air pressure corresponding to the desired engine power and ambient EECU pressure a waste

gate valve is directly mounted at the turbo charger.

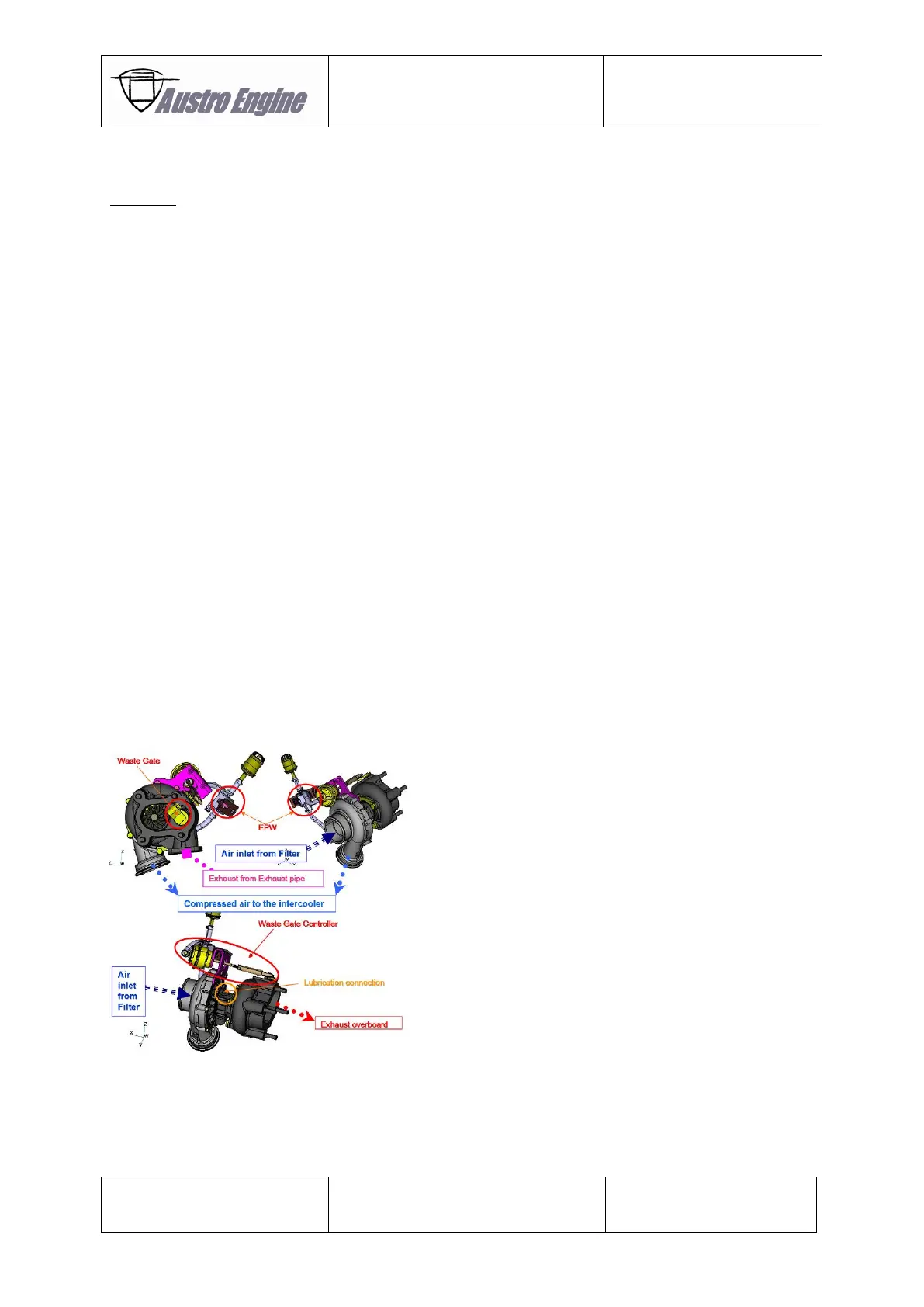

Turbo Charger

The EECU controls the turbocharger by using RPM, measured manifold pressure and barometric

pressure to determine a target value for manifold pressure. The EECU then sends an output signal

corresponding to this target value to a boost pressure actuator, which actuates the waste gate.

The boost pressure actuator uses air pressure from the compressor side of the turbocharger to control

a diaphragm box. This diaphragm box is mechanically linked to the turbo charger waste gate and

regulates the amount of exhaust gas that bypasses the turbocharger turbine and therefore manifold

pressure.

The figure shows the turbocharger with the boost pressure actuator, air filter for the boost pressure

actuator and the waste gate controller which is attached to the turbo charger.

Fig. 01 - 8 Turbo Charger Operation

Loading...

Loading...