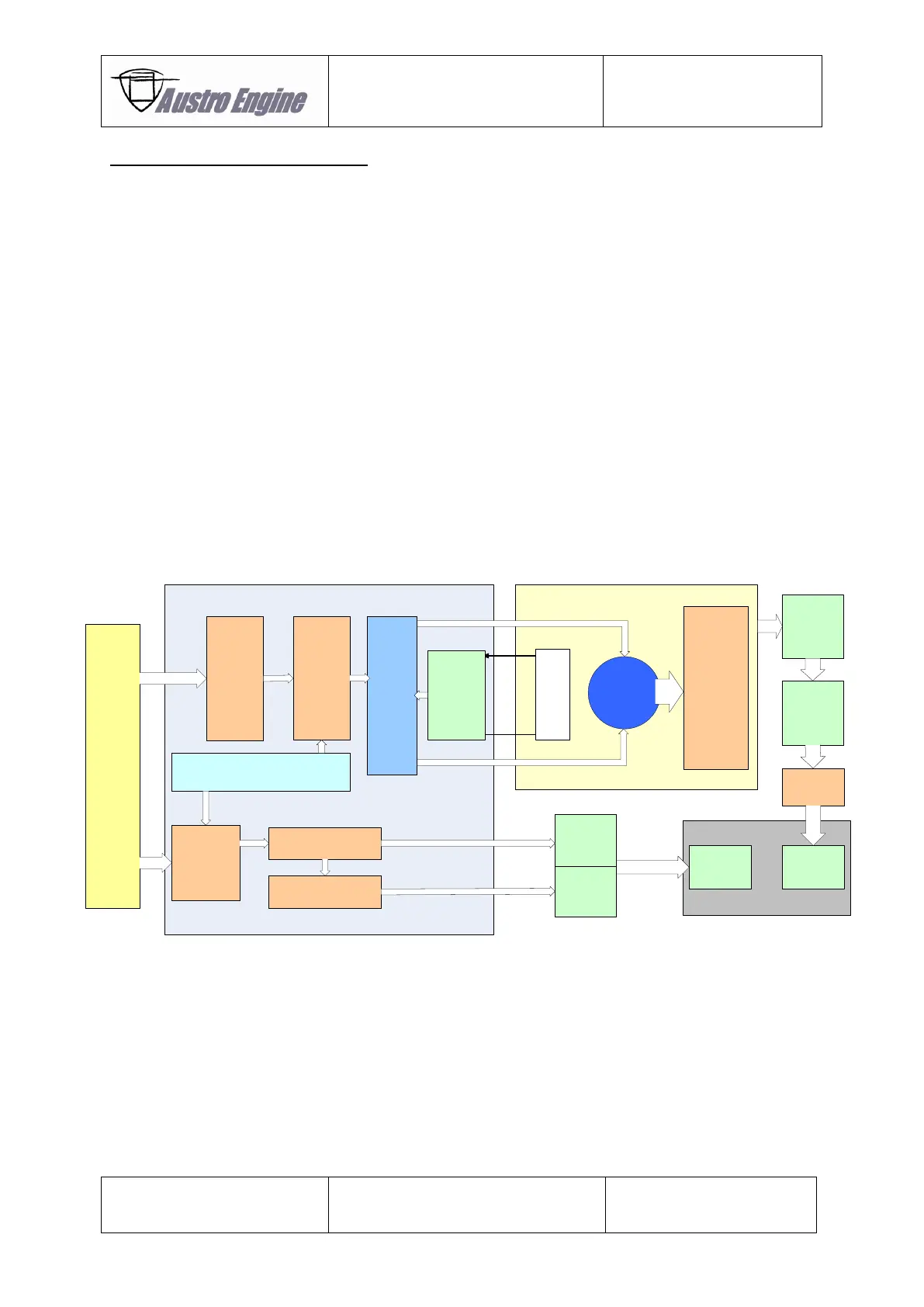

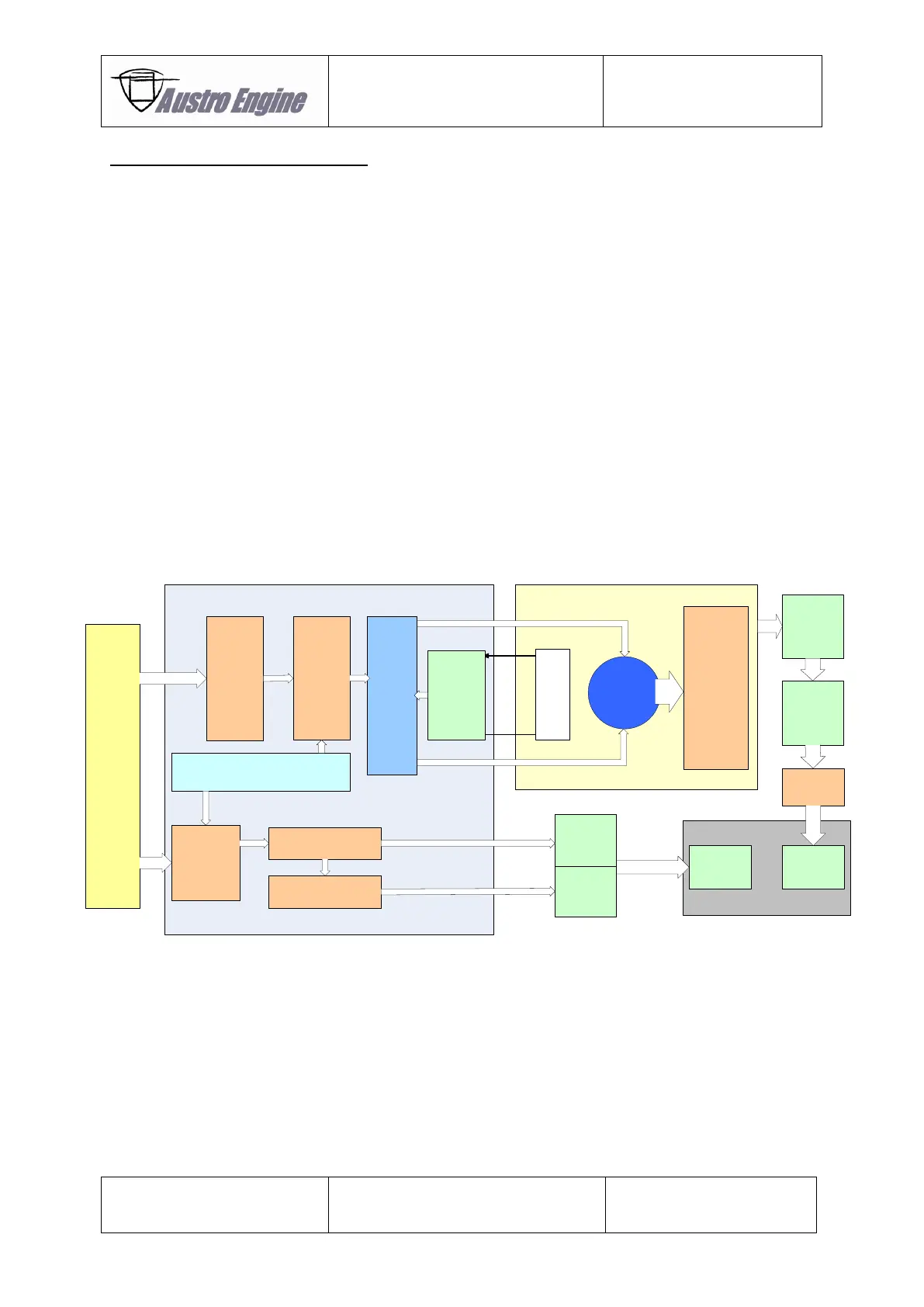

Governor Functional Description:

The propeller speed is conventionally controlled and kept by a mechanical propeller governor

but the set point of the governor is adjusted by an electric motor controlled by the EECU.

This electric motor substitutes the conventionally used Bowden cable and if e.g. the connection to the

set point actuator fails, the set point remains unchanged and the governor controls the propeller

speed to the last set-point.

The desired propeller speed set point is calculated depending on the power lever sensor position.

(refer to Governor Interface)

The current engine speed divided by the gear box ratio is used to compute the propeller speed

deviation which is then converted into an output ratio for the actuator

The propeller speed set point is set by an electric motor (actuator) in the governor system.

The governor controls the propeller speed via the propeller blade pitch angle

The actuator control ensures together with the monitoring a safe and correct actuation

If the set point is reached the actuator is deactivated and the governor controls the engine speed to

the set point.

Overview of propeller speed control:

Fig. 01 - 27 Propeller Speed Control

Engine

Governor

End

Stops

ECU

Set Point

Actuator

(Motor)

Propeller

Speed

Actuator

Control

Propeller

Speed

Control

End Stop

Feedback

Propeller

Pitch

Power

Lever

Sensor

Injection Quantity

Calculation

Engine

Torque

Injection

Quantity

Engine Speed Information

Actuator

Set Point

Calc

Demanded

Torque

Calculation

Desired

Propeller

Speed

Boost Pressure

Calculation

Boost

Pressure

Gear

Box

Engine

Speed

Loading...

Loading...