80-0000010B OM

129

It is not allowed to reduce brakes pedal travel to less than the values specified in subsection

3.7.3.1, as it leads to premature wear of the friction discs and overheating of the brakes.

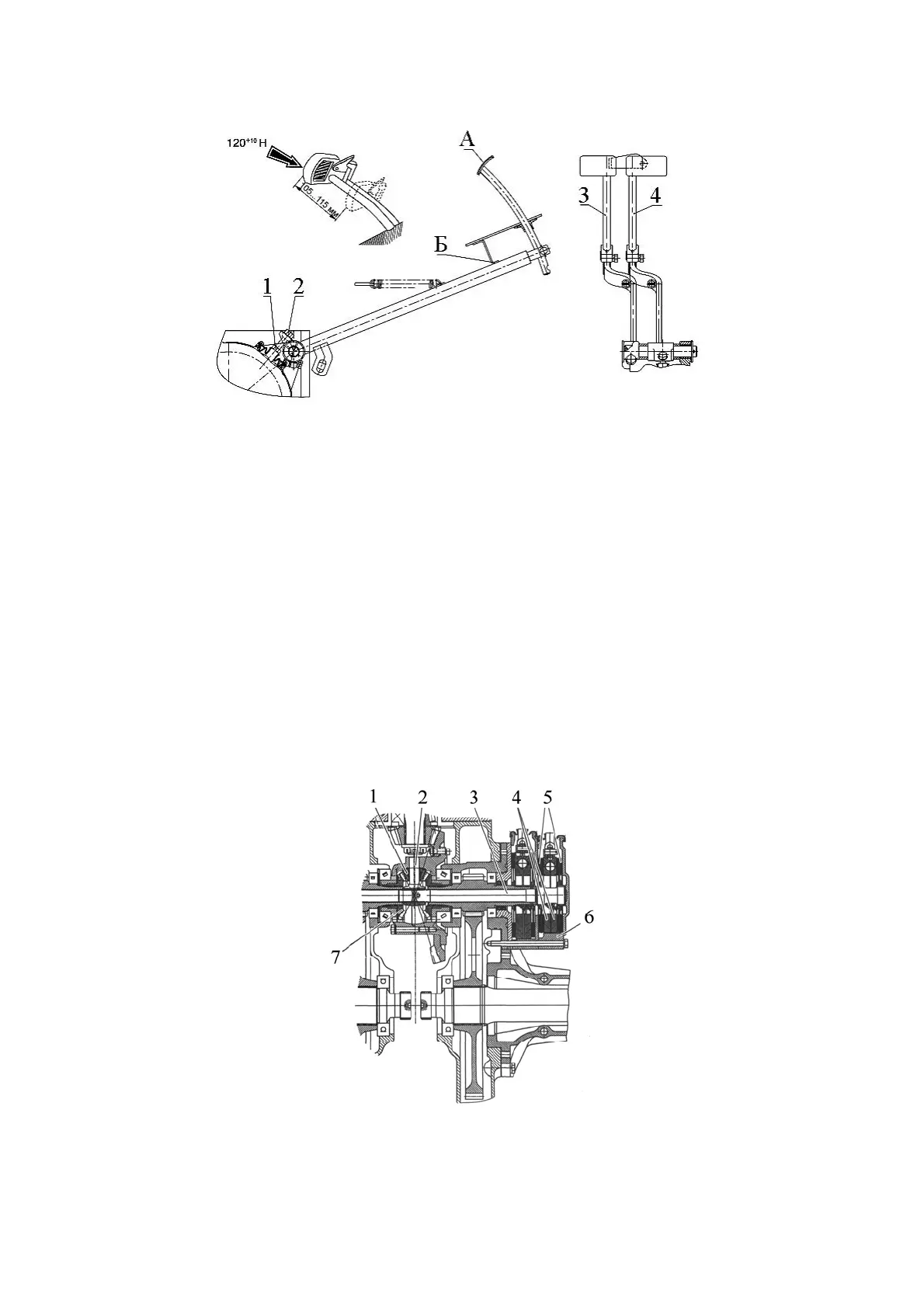

1 – locknut; 2 – adjusting bolt; 3 – left pedal; 4 – right pedal

Figure 3.7.3 – Service brakes control adjustment

ATTENTION: INGRESS OF LUBRICANT INTO DRY FRICTION BRAKE CAUSES OILING

OF THE FICTION DISCS, REDUCE OF FRICTION FORCE BETWEEN THEIR WORKING

SURFACES – THE BRAKES “DO NOT GRIP”. IN THIS CASE DISMANTLE THE BRAKE,

ELIMINATE OIL LEAKAGE, AND RINSE OILED DISCS WITH BENZINE AND LET THEM DRY

FROM 5 TO 8 MINUTES. AFTER ASSEMBLY ADJUST THE SERVICE BRAKES CONTROL,

AS SPECIFIED ABOVE!

3.7.3 Parking brake

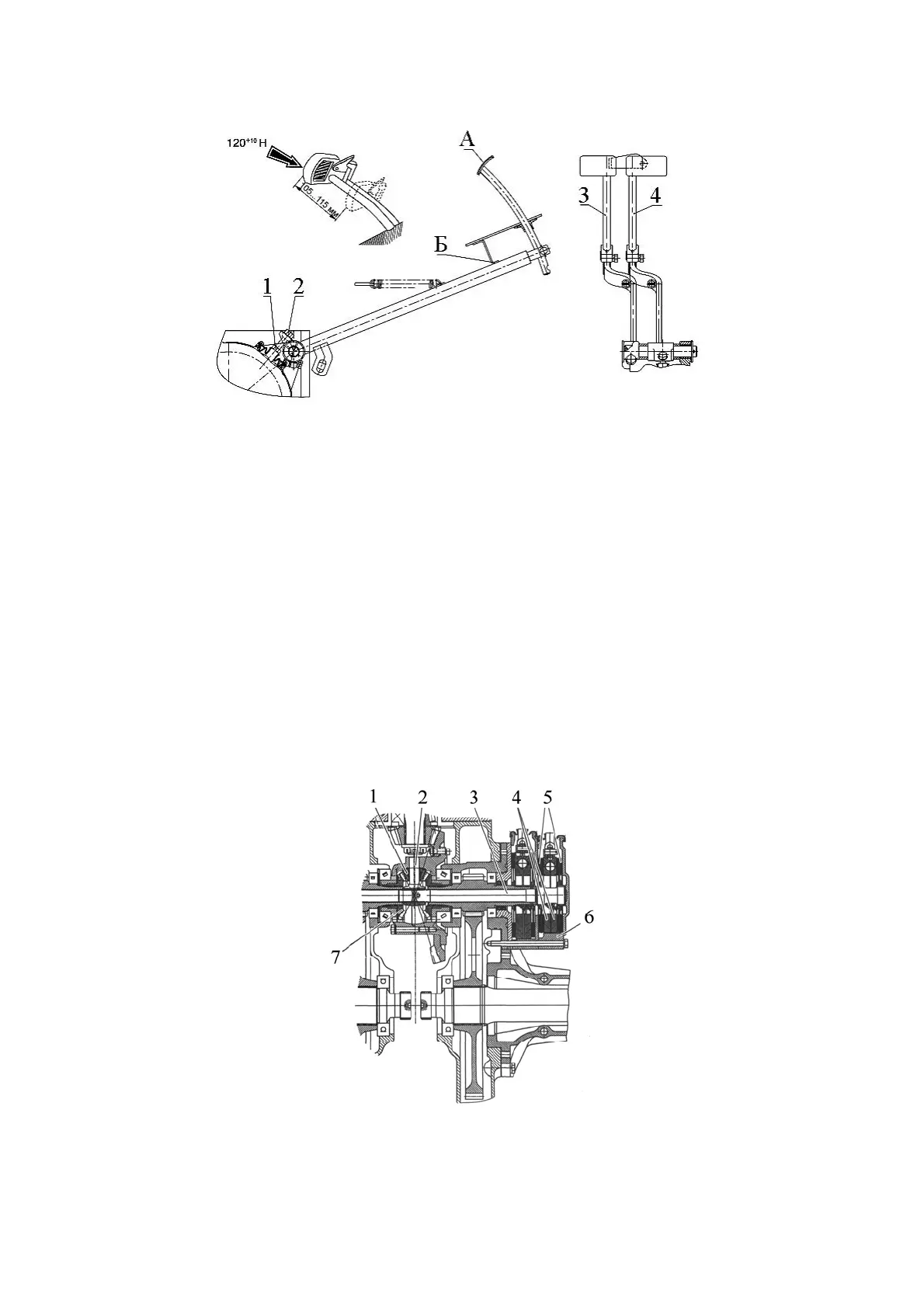

As a parking brake separate brake is used with manual continuous drive. The parking

brake type is dry.

The parking brake is mounted on the shell of the right service brake. When tractor is

moving rotation from differential cross 2 (figure 3.7.4) through shaft 3 is transmitted to friction

discs 5. When shifting parking brake lever 17 (figure 3.7.5) towards yourself pressure discs 4

(figure 3.7.4) rotating relatively each other, move apart, braking friction discs 5 and shaft 3

connected to them, which is connected to differential cross 2, blocking through planetary gears

1 axle shaft gears 7 of the differential, hub and final drives and tractor wheels. It is allowed to

use parking brake short moment for braking of the tractor if the service brakes are out of order.

1 – planetary gear; 2 – differential cross; 3 – parking brake shaft; 4 – pressure discs; 5 – friction

discs; 6 – parking brake housing; 7 – axle shaft gear.

Figure 3.7.4 – Parking brake installation

Loading...

Loading...