80-0000010B OM

161

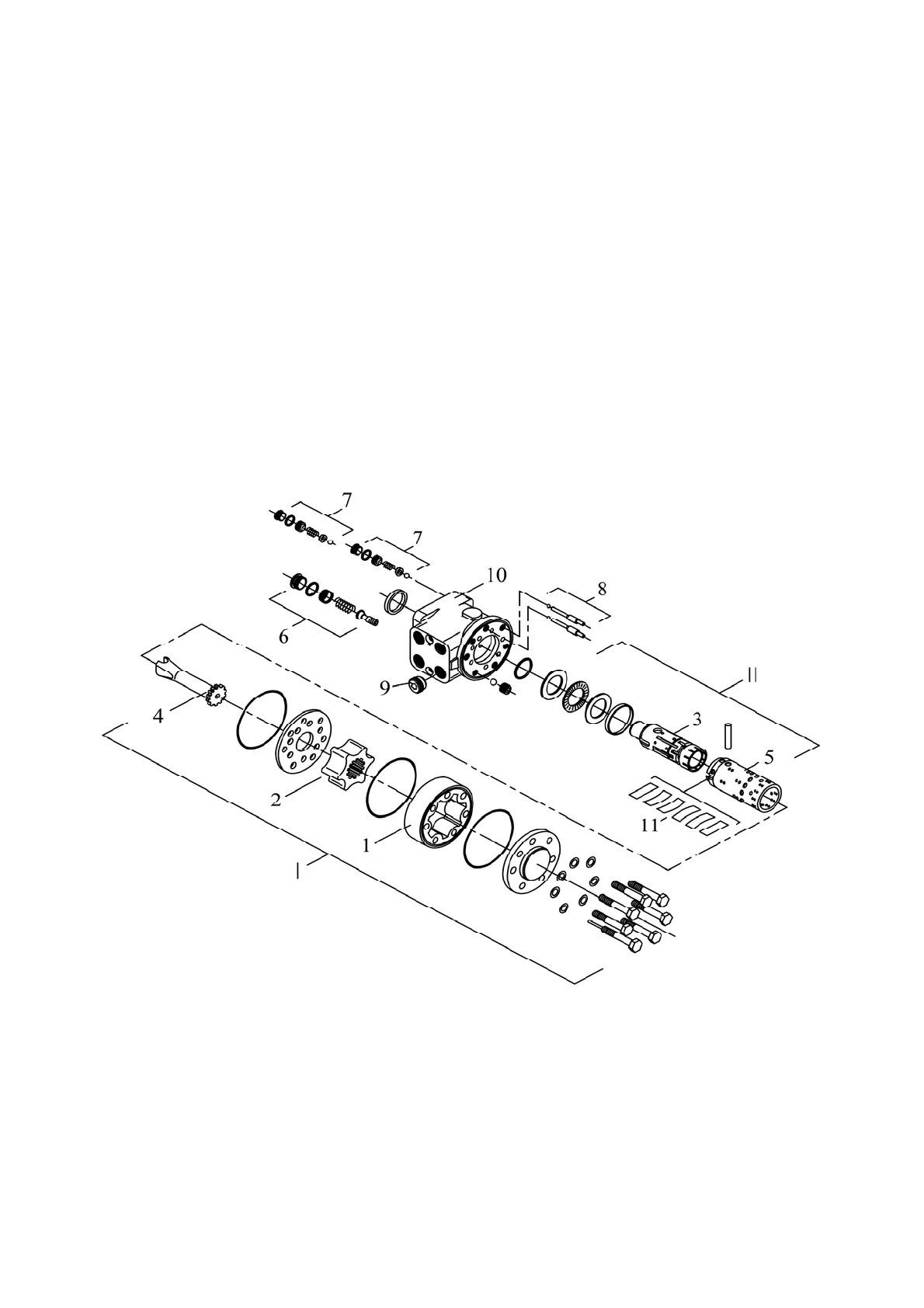

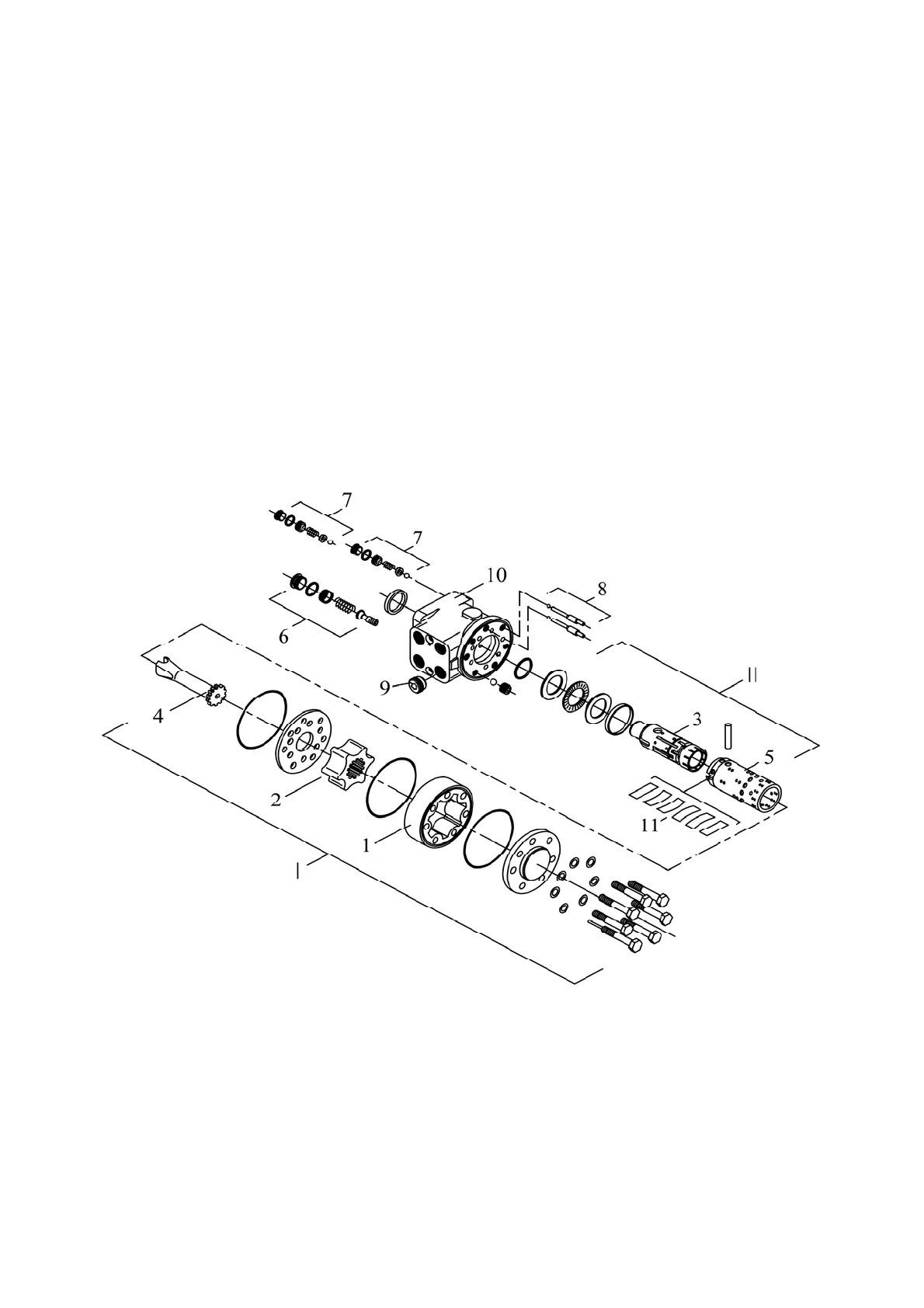

3.12.2 Dosing pump

Dosing pump is of gerotor type with an “open center” and no reaction on the steer-

ing wheel includes housing 10 (figure 3.12.4), pumping unit I, distributor II, two anti-shock

valves 7, safety valve 6, two air-inlet valves 8 and back-flow valve 9.

Gerotor pumping unit I consists of stator 1 secured on housing 10 and rotating rotor

2, connected to spool 3 through cardan shaft 4.

Distributor II consists of sleeve 5, set of plate springs 11 and spool 3, connected by

splines with shank of steering column drive shaft.

The back-flow valve provides operation of the dosing pump in the manual control

mode as a manual pump, when the feed pump is faulty.

Safety valve 6 prevents pump and HSC hydraulic system from overloading, limiting

maximum pressure in the pressure line in the range from 14 to 15 MPa.

Anti-shock valves 7 (right and left) protect hoses of cylinder hydraulic lines from

peak pressures, arising in the cavities of the hydraulic cylinder at the moment of steering

wheels running-over obstacles. Anti-shock valves adjusting pressure is from 20 to 21 MPa.

Air-inlet valves 8 (right and left) prevent HSC hydraulic system from vacuum and

cavitation when anti-shock valves actuate.

1 – stator; 2 – rotor; 3 – spool; 4 – cardan shaft; 5 – sleeve; 6 – safety valve;

7 – anti-shock valves; 8 – air-inlet valves; 9 – back-flow valve; 10 – housing; 11 – plate

springs; I – pumping unit; II – distributor.

Figure 3.12.4 – Dosing pump

Loading...

Loading...