80-0000010B OM

227

- if air pressure drop is constantly observed in tyres, make sure to identify the fault

and eliminate it;

- check the inflation pressure of tyres filled with water solution, when the valve is lo-

cated at the very top of the tyre;

- use of tyre sizes, not specified in the manual, is only possible upon agreement

with the manufacturer;

- when choosing and buying new tyres follow the instructions of this Operator’s

manual.

Incorrect mounting and dismounting of tyres results in damage to elements of tyre

structure. In farms, tyres shall be mounted and dismounted in specially designated areas

or rooms. As a rule, tyres are mounted/dismounted on a special stand, but manual mount-

ing/dismounting of tyres is also permitted (by means of tyre levers and other appliances).

Mount tyres of the same size, model and design on one axis. Periodical rearrangement of

wheels precludes their uneven wear. Do not mount wheels with different wear rates on one

axis. It is not recommended to use old inner tubes for the new tyres;

- when setting the track, it is obligatory to provide equal distance for opposite

wheels with relation to a vertical plane crossing the center of the tractor. When mounting

wheels remember of the correct direction of tyre rotation and of sufficient safe distance be-

tween the wheel and other elements of tractor design;

- do not operate the tractor with long-lasting wheel skidding and overload on the

wheels: with heavy implements (having weight exceeding the values permitted for the trac-

tor) or with soil processing implements, having resistance which is too much for the tractor

in the given soil conditions;

- avoid abrupt start of movement, hard braking, sharp turns, long-lasting wheel

skidding as tractor gets stuck.

IT IS FORBIDDEN TO OPERATE THE TRACTOR AND TO PUT IT FOR LONG-TERM

PARKING WITH TYRES DAMAGED OR DEFLATED.

4.2.8.3 Tyre inflation

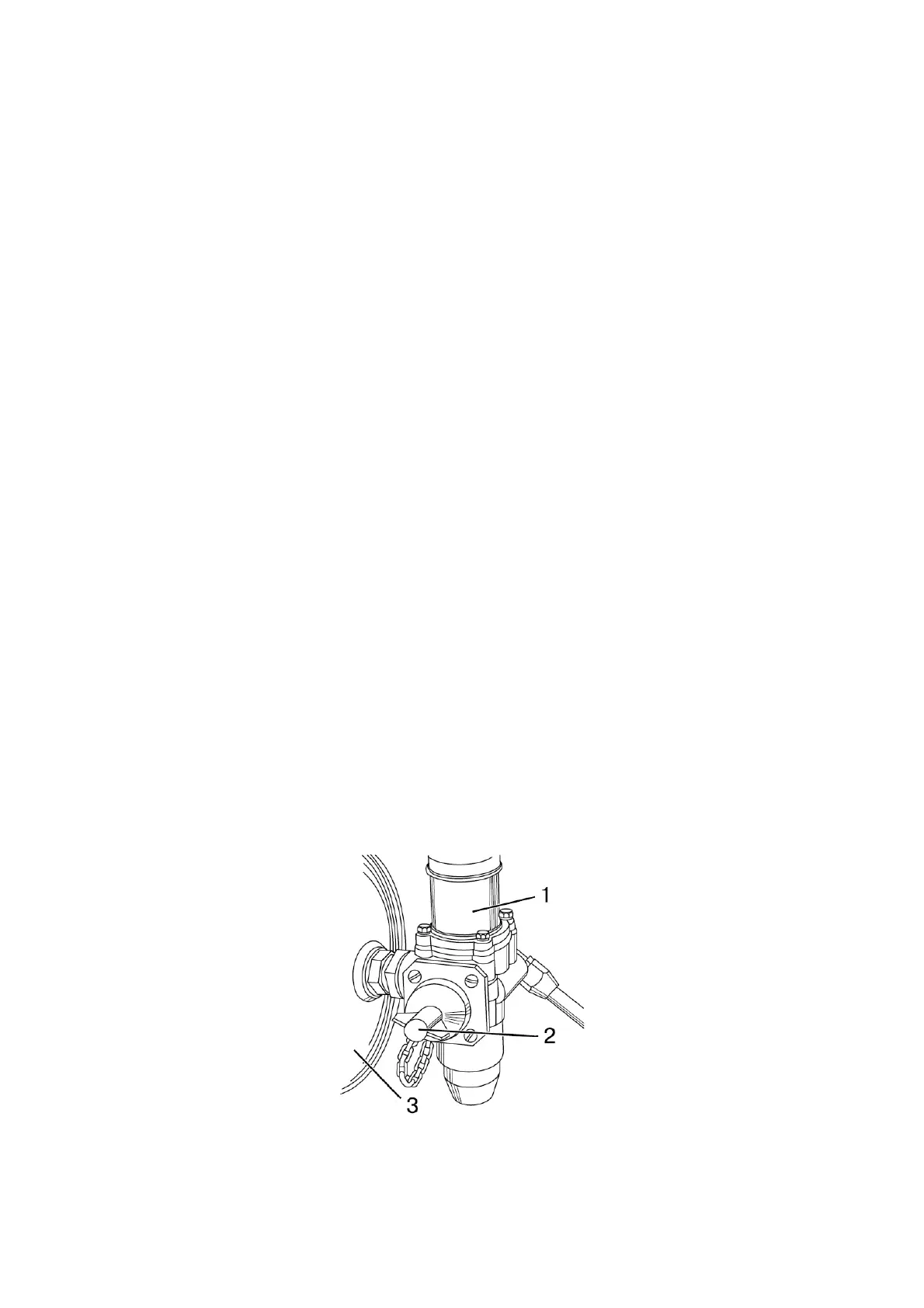

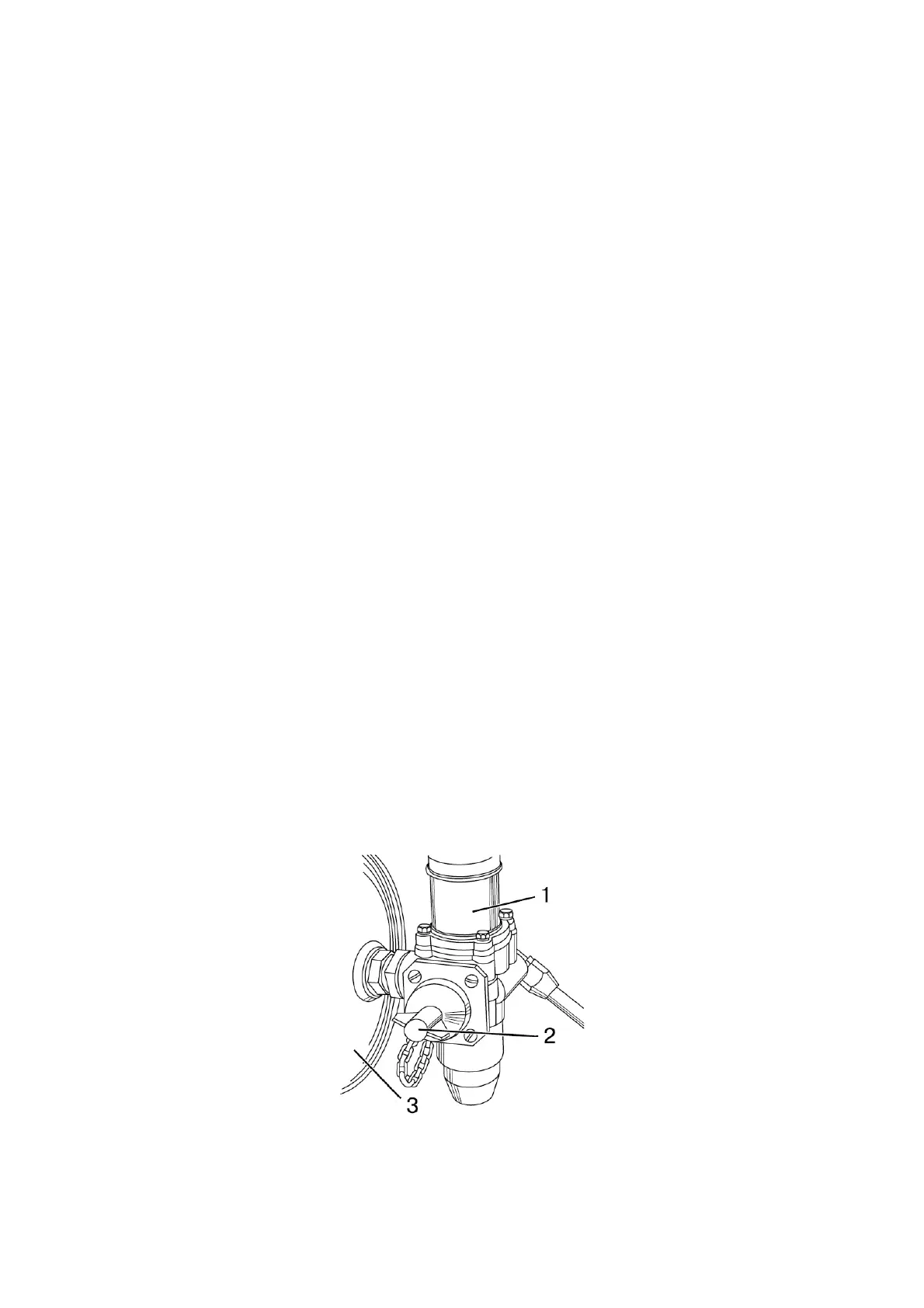

Inflate tyres through the air bleed valve of pressure regulator 1 (figure 4.2.2), for this

do the following:

- let air out of a tank 3 of the pneumatic system through the condensate removing valve;

- unscrew winged nut 2 of the air bleed valve fitting;

- connect a hose to inflate tyres to the air bleed fitting and to the tyre valve;

- start the engine and inflate the tyre to reach the necessary pressure, while control-

ling it with a tyre manometer;

- detach the hose from the tyre valve and from the air bleed fitting;

- screw the winged nut back on the air bleed valve fitting.

1 – pressure regulator; 2 – winged nut; 3 – pneumatic system tank.

Figure 4.2.2 – Tyre inflation

Loading...

Loading...