80-0000010B OM

349

7. POSSIBLE FAILURES AND INSTRUCTIONS FOR TROUBLE-

SHOOTING

7.1 Possible failures of the engine and instructions for troubleshooting

A list of possible engine failures of BELARUS-80.1/82.1/820 tractors and instruc-

tions for their troubleshooting are given in table 7.1.1.

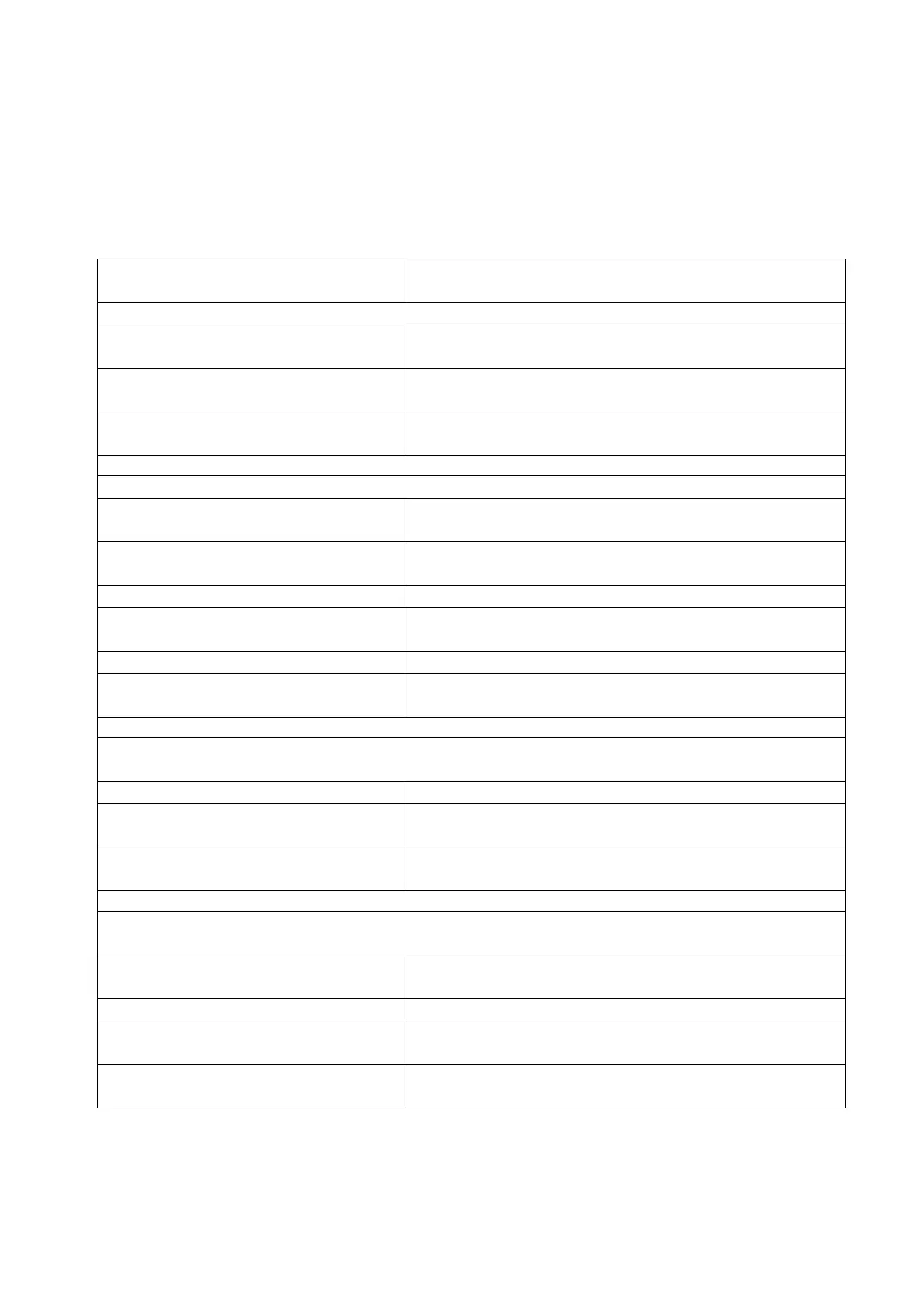

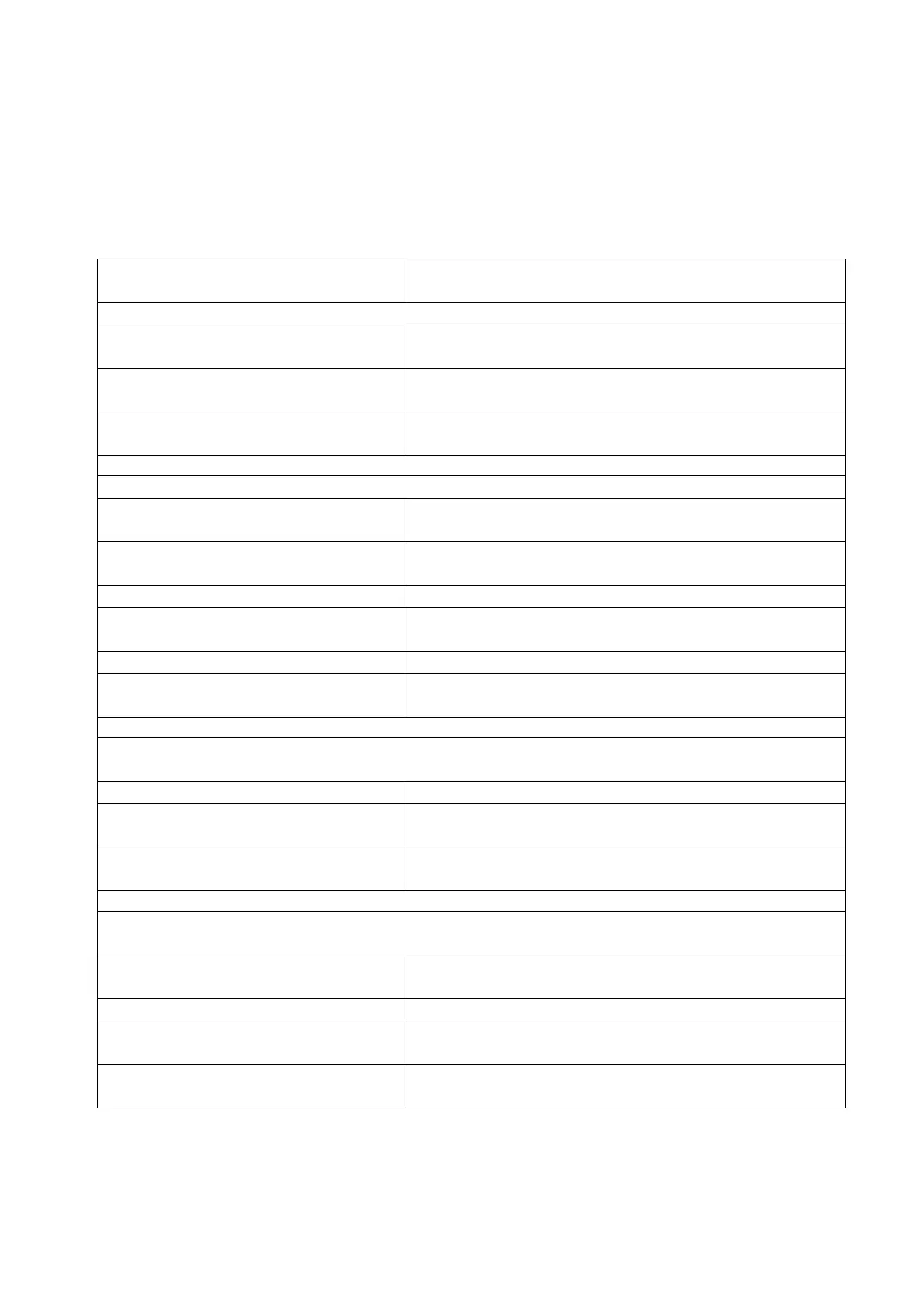

Table 7.1.1

Failure,

external manifestation, cause

Troubleshooting

The engine will not start

Air in fuel system Bleed the system with a manual fuel priming pump. Elim-

inate air suction in the fuel system

Fuel pump failure Remove the fuel pump off the engine and send it to

a workshop for repair

Fuel filters are clogged Rinse the coarse fuel filter and replace the filter

cartridge of the fine fuel filter

The engine does not increase power

Fuel pump control lever does not

reach the stop

Adjust the control rods of fuel pump

Filter cartridge of the fine fuel filter is

clogged

Replace the filter cartridge of the fine fuel filter

Nozzles are out of order Detect the failed nozzles, rinse and adjust them

Fuel injection advance angle is in-

correctly adjusted

Set the recommended fuel injection advance angle

Engine air cleaner is clogged Perform maintenance of the air cleaner

Fuel pump is out of order Remove fuel pump off the engine and send it to a

workshop for repair

The engine fumes at all operation modes: black smoke comes out of the

exhaust pipe

Engine air cleaner is clogged Perform maintenance of the air cleaner

Nozzle atomizer needle is stuck Detect the failed nozzle, rinse or replace the atom-

izer, adjust the nozzle

Fuel pump is out of order Remove the fuel pump off the engine and send it to

a workshop for repair

The engine fumes at all operation modes: white smoke comes out of the

exhaust pipe

The engine operates with over-

cooling

Warm up the engine, during operation maintain the

coolant temperature in the range 85-95°С

Water ingress into fuel Replace the fuel

No gap between gaps and rocker

arms

Adjust gaps between valves and rocker arms

Fuel injection advance angle is in-

correctly adjusted

Set the recommended fuel injection advance angle

Loading...

Loading...