80-0000010B OM

364

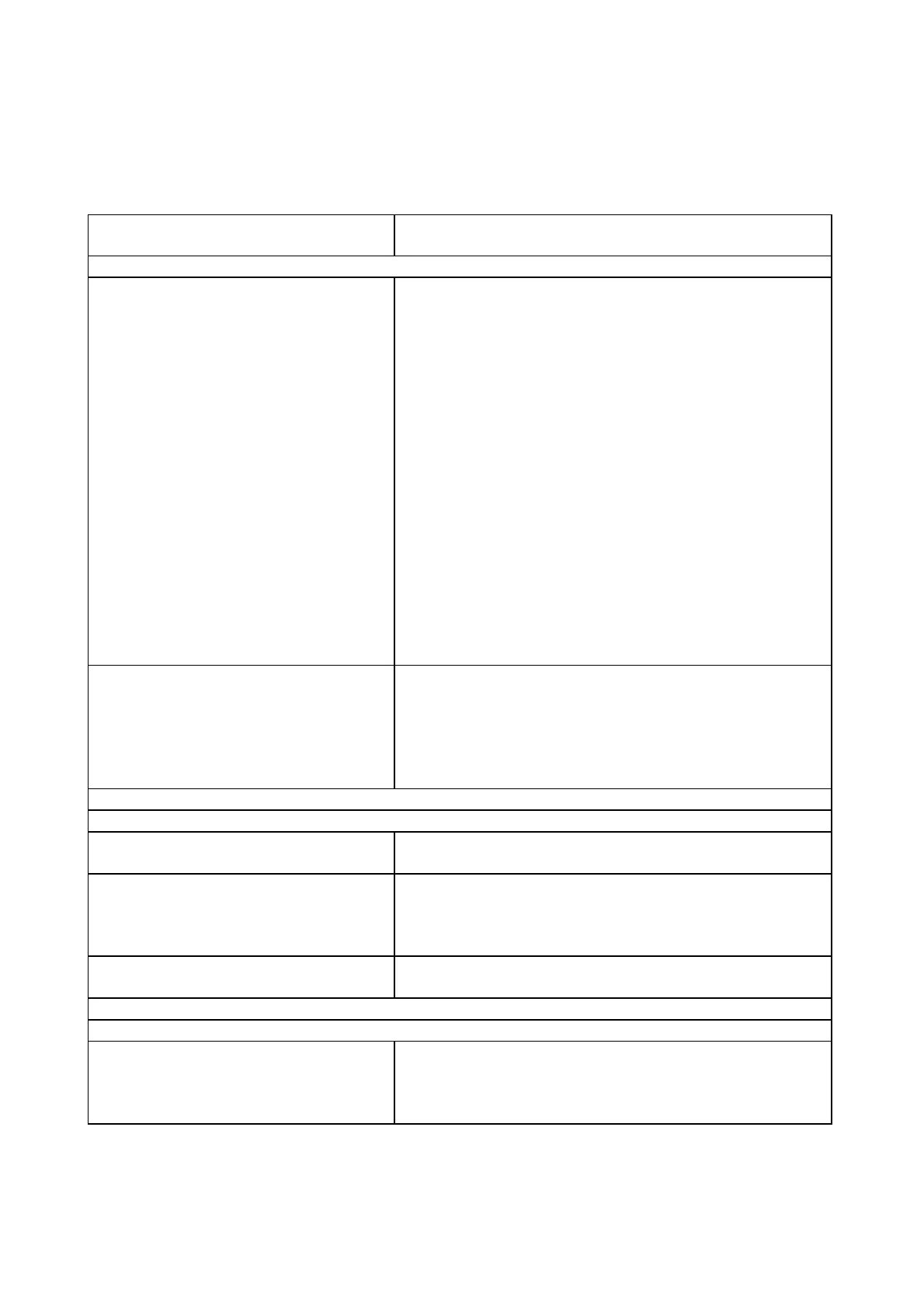

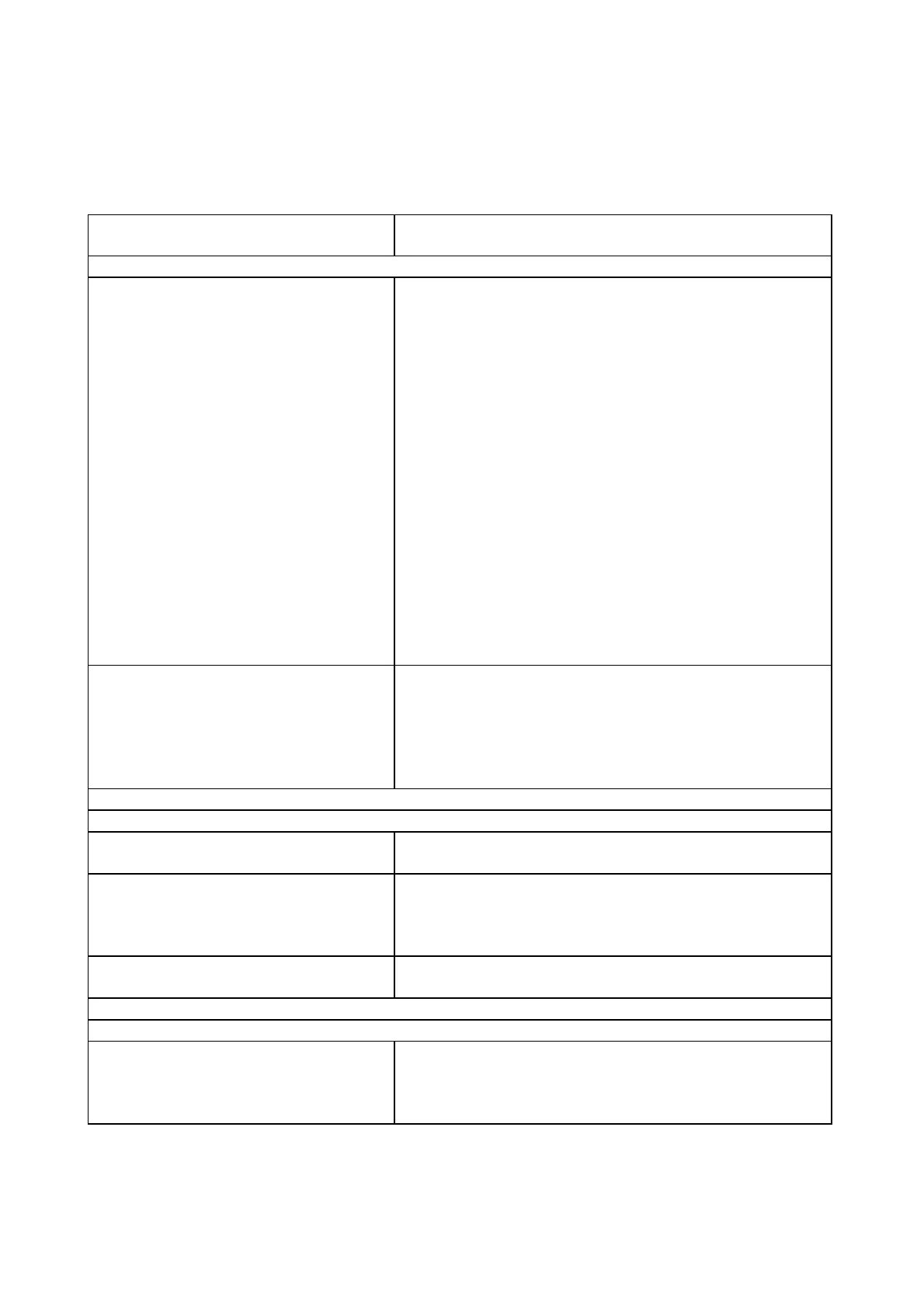

7.11 Possible failures of the hydrostatic steering control with HPS housing

and instructions for troubleshooting

The list of possible failures of the hydrostatic steering control with HPS housing and

instructions for troubleshooting are given in Table 7.11.1.

Table 7.11.1

Failure,

external manifestation, cause

Troubleshooting

Great effort at the steerin

wheel

No pressure or insufficient pressure

in the charge hydraulic line of steer-

ing control (it should make from

14.5 to 16.0 MPa when turning the

steering wheel against the stop) due

to the following reasons:

- HSC hydraulic system was not bled

- faulty adjustment of dosing pump

safety valve (low pressure)

- faulty feed pump (the pump fails to

increase pressure because of low

volume efficiency)

Bleed the HSC hydraulic system by turning the

steering wheel and moving guide wheels from left-

most to the right-most position position (stop-to-stop

position) for 2-3 times

Contact your dealer. The safety valve needs to be ad-

justed for the required pressure

1)

. The operation shall

be performed by maintenance department.

1)

Contact your dealer. The pump fails to increase

pressure because of low volume efficiency

Excessive friction or blocking up of

steering drive mechanical compo-

nents

Eliminate friction in the steering drive, which re-

quires the following:

- reduce rate of tightening of the upper nut;

- grease friction surfaces of plastic bushings;

- eliminate contact of cardan yokes on sides of

the steerin

drive bracket

Rotatin

the steerin

wheel does not turn the

uide wheels

No oil in HSC housing Fill the HPS housing with oil to reach the required

level and bleed the HSC hydraulic system

Faulty adjustment of dosing pump

valves. Safety valve adjustment

pressure is higher than anti-shock

valves’ ad

ustment pressure

Contact your dealer. It is necessary to adjust safety

and anti-shock valves to the required pressure. The

operation shall be performed by the maintenance

department

1)

Seals of steering hydraulic cylinder

piston are worn out

Repair or replace the hydraulic cylinde

Dosin

pump fault

steerin

wheel

oes on rotatin

after the turn

Gripping of sleeve with the spool

(possibly due to contamination)

Contact your dealer. It is needed to rinse the dosing

pump parts. Assembly and check of operation shall

be performed by the maintenance service in ac-

cordance with the manufacturer’s instructions

1)

Loading...

Loading...