80-0000010B OM

340

6.5 Seasonal technical maintenance

Carrying out of seasonal maintenance service shall be combined with operations of

scheduled maintenance services. Scope of work which shall be carried out during season-

al maintenance service, is given in Table 6.5.1.

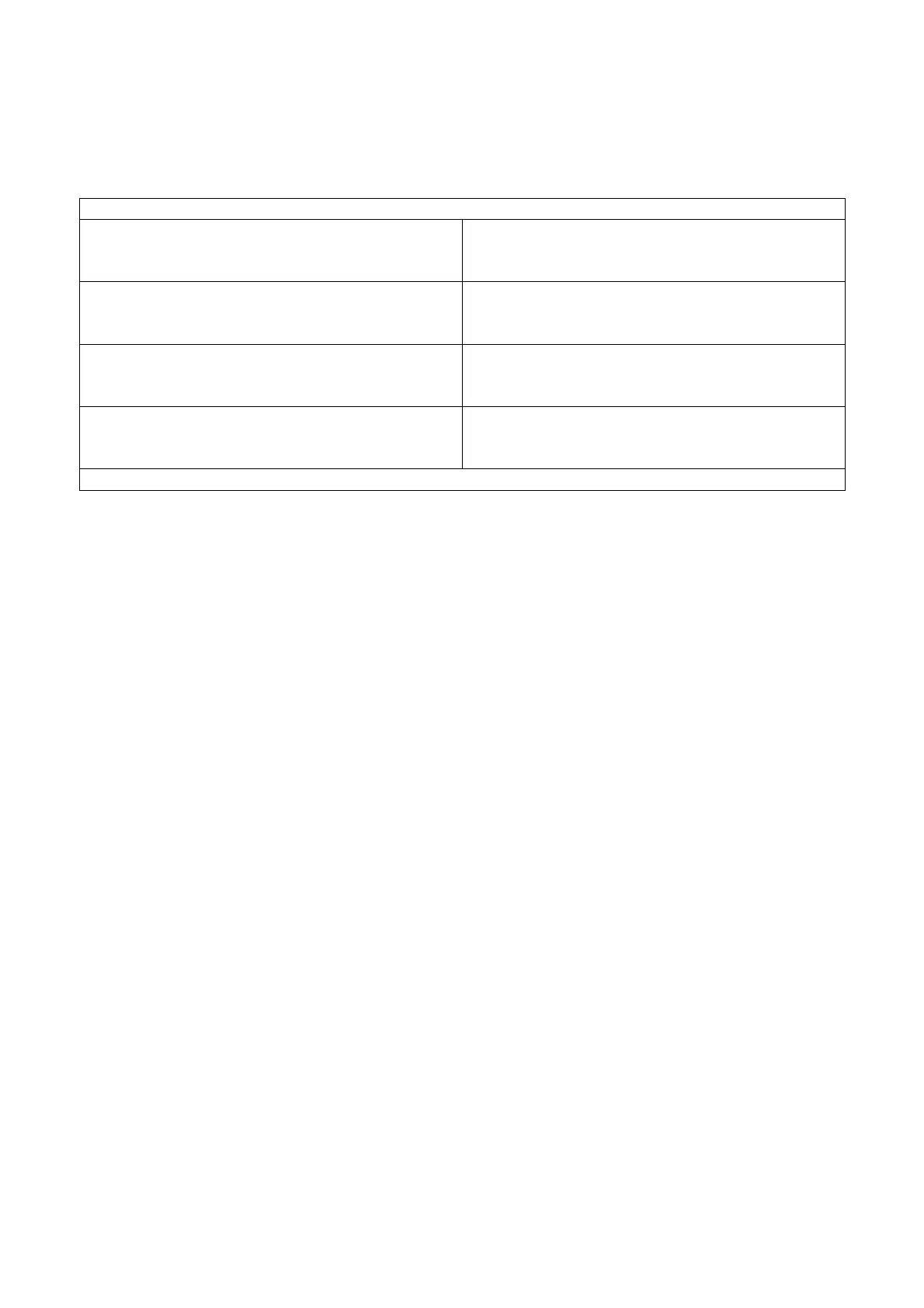

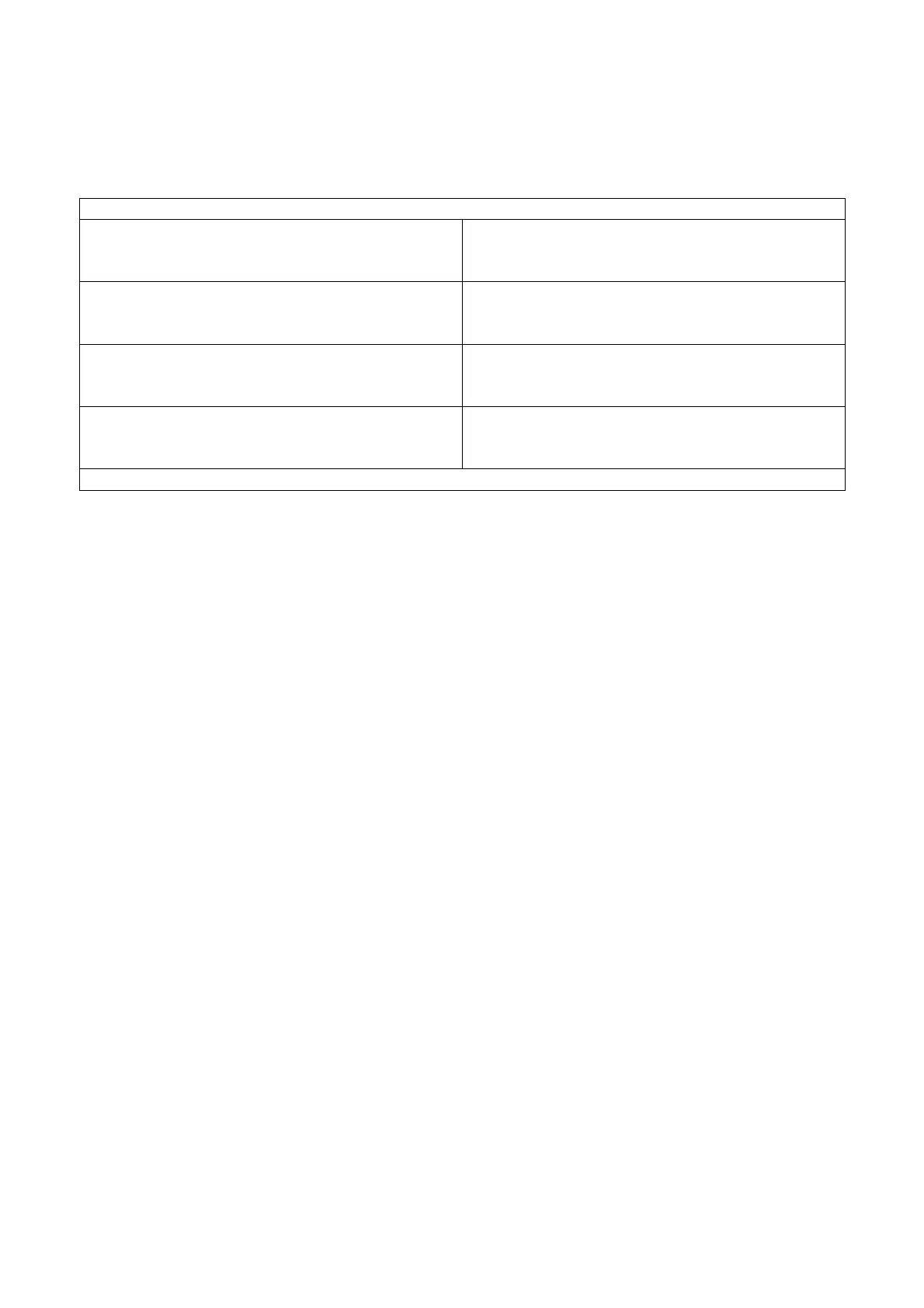

Table 6.5.1 – Seasonal maintenance services

Scope of work

When changing into autumn-winter period

(with settled daily average temperature below

+5С)

When changing into spring-summer period

(with settled daily average temperature

above +5С)

Replace summer oil grades by winter ones

in engine crankcase in accordance with Table

6.7.1

Replace winter-grade oils with summer-

grade ones in the engine crankcase in ac-

cordance with Table 6.7.1.

Replace summer-grade oils with winter-

grade ones in HPS body in accordance with

Table 6.7.1

Replace winter-grade oils with summer-

grade ones in HPS body in accordance with

Table 6.7.1.

Replace summer-grade oils with winter-

grade ones in HLL tank in accordance with

Table 6.7.1

1)

Replace winter-grade oils with summer-

grade ones in HLL tank in accordance with

Table 6.7.1.

1)

1)

The operation shall be performed on tractors equipped with HPS.

6.6 Safety measures during TM and repair operations

6.6.1 General safety measures

It is forbidden to raise the tractor hood with the engine running.

Maintenance (repair) operations shall be carried out only while the engine is not

running and the rear and side PTO are stopped. Hinged implements shall be in their low-

ered position, the tractor shall be stopped with the parking brake.

Observe safety requirements while using lift-and-carry means of transport.

During inspection of units under control and adjustment, use a portable lamp with

voltage of not more than 36V. The lamp shall be protected by wire guard.

Tools and accessories for TM shall be in a proper operating condition, correspond

to their assignment and ensure safe operation.

In order to avoid burns, be careful while draining (refilling) the coolant from the en-

gine cooling system or hot oil from the engine, hydraulic systems of RLL, HSC and HPS,

transmission bodies. Avoid contact with hot surfaces of the above mentioned units.

Mounting and dismounting of the engine shall be carried out by means of a cable,

fastened to eye-bolts on the engine.

Do not introduce any alterations in the design of the tractor or its separate parts

without authorization of the manufacturer. Otherwise the tractor after-sales service warran-

ty is terminated.

6.6.2 Safety precautions for exclusion of hazardous situations related to accumula-

tor batteries and fuel tank.

During maintenance of the accumulator batteries, do the following:

- avoid skin contact with electrolyte;

- clean the battery with wiping material moistened with aqua ammonia solution

(ammonium hydroxide);

- while checking the electrolyte level, refill distilled water only;

- do not check the battery charge by means of the terminal short circuit;

- do not connect the accumulator battery with reversed polarity.

Loading...

Loading...