80-0000010B OM

352

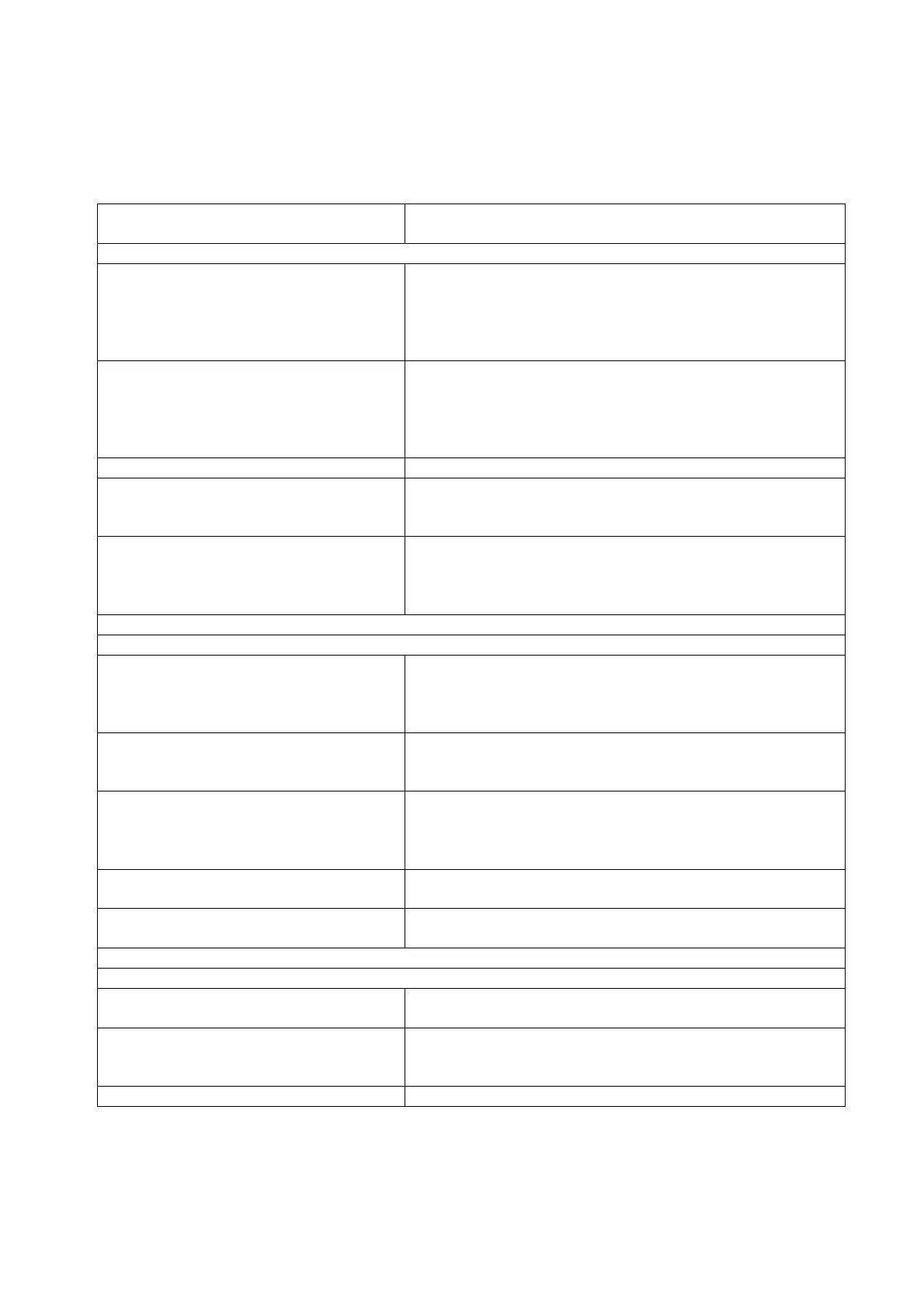

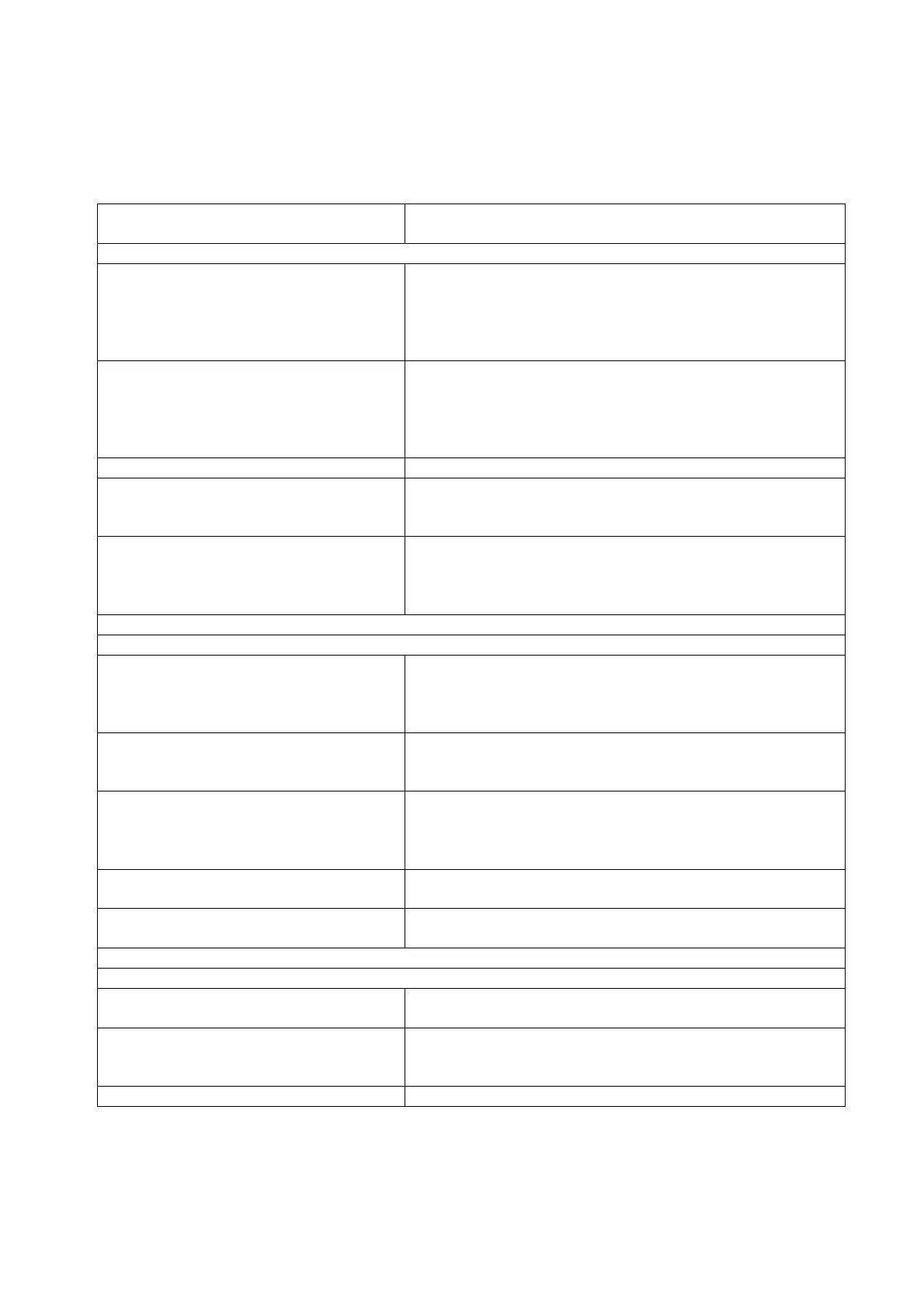

7.2 Possible failures of the clutch and instructions for troubleshooting

The list of possible failures of the clutch and instructions for their troubleshooting

are given in table 7.2.1.

Table 7.2.1

Failure,

external manifestation, cause

Troubleshooting

Clutch will not transfer full torque

“slippin

”

There is no gap between the shift-

er’s bearing and the release levers

- “semi-disengaged clutch” (in-

sufficient free travel of the clutch

pedal

djust the clutch pedal free travel as described in

section 3.2.3.2 “Adjustment of coupling clutch pe-

dal free travel.”

Coupling clutch does not engage

in full (the clutch lever does not re-

turn to its initial position) when re-

leasing the clutch pedal due to

malfunction of clutch control

djust the clutch pedal free travel as described in

section 3.2.3.2 “Adjustment of coupling clutch pe-

dal free travel .”

Driven disk linin

s are worn out Replace the linin

s or driven disk assembl

Oiling of linings of driven disks due

to ingress of oil into the dry com-

partment

Identify and eliminate the cause of ingress of oil

into the dry compartment

Insufficient force of compression

springs (shrinking of springs at

prolonged slipping and overheating

of the clutch

Replace the compression springs

Clutch couplin

will not full

disen

a

e

“clutch

rabs and shudders”

Clearance between the shifter’s

bearing and release lever is in-

creased (large clutch pedal free

travel

djust the clutch pedal free travel as described in

section 3.2.3.2 “Adjustment of coupling clutch pe-

dal free travel .”

Release levers do not adjoin even-

ly the release bearing

djust the position of release levers according to

section 3.2.2.4 “Adjustment of release levers of

couplin

clutch”

Excessive warping of driven disks Check the face run-out of driven disk linings

against the outer diameter of hub splines – it shall

make not more than 0.8 mm on the radius of 165

mm. If impossible to rectif

, replace the disks.

Dragging of driven disk hub on

transmission shaft splines

Grind the splines ensuring travel of the disk on the

transmission shaft

Transmission shaft support bear-

in

in fl

wheel is destro

ed

Replace the bearing

In

ress of oil into the dr

section of couplin

clutch

Wear of collar that seals the

c

ankshaft

Replace the colla

The bearing cover of drive shaft of

rear PTO drive during tractor cou-

plin

after repair is pressed out

Install a new cover o

set straight the old cove

Wear of collar of shifter bracke

Replace the colla

Loading...

Loading...