80-0000010B OM

283

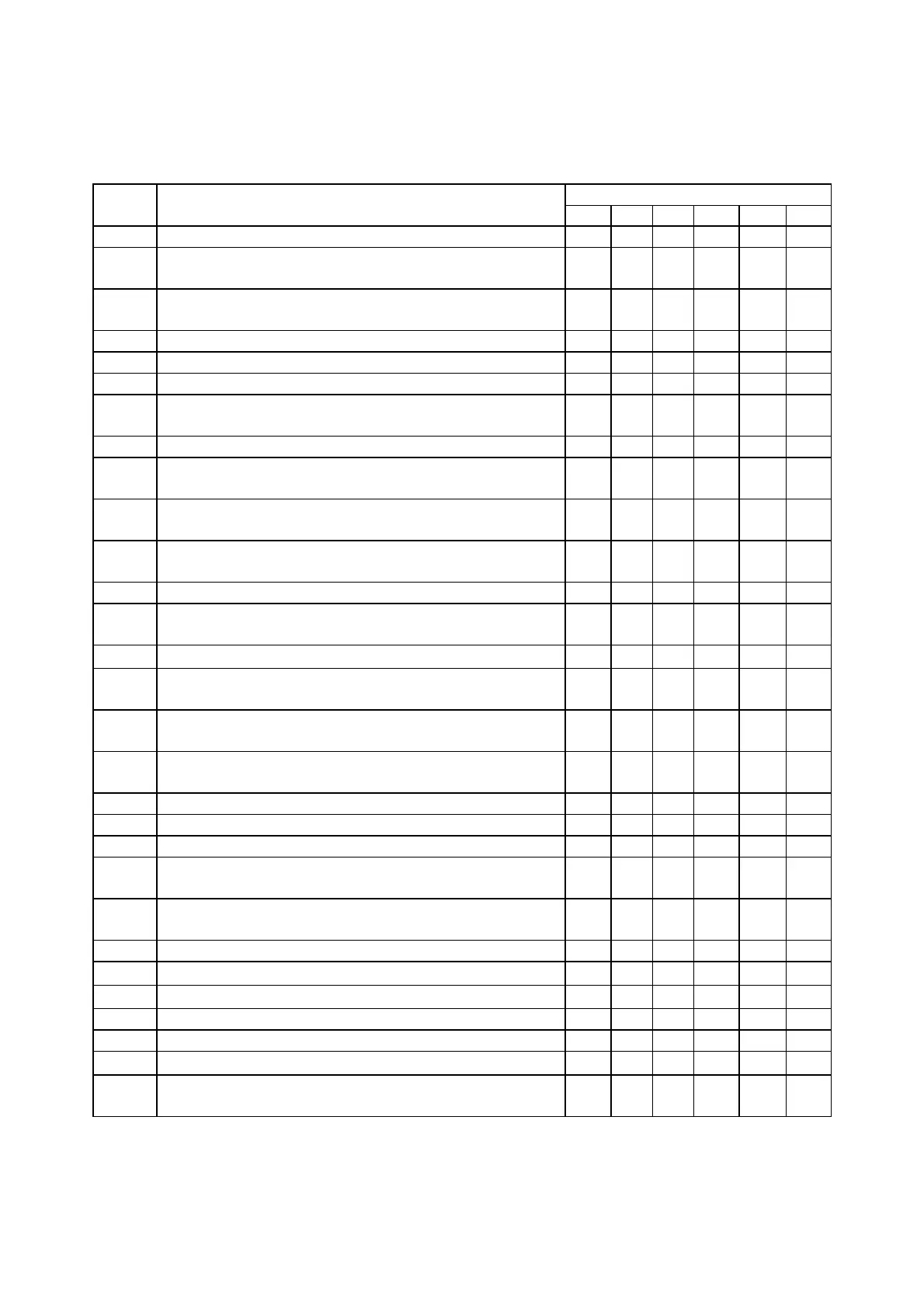

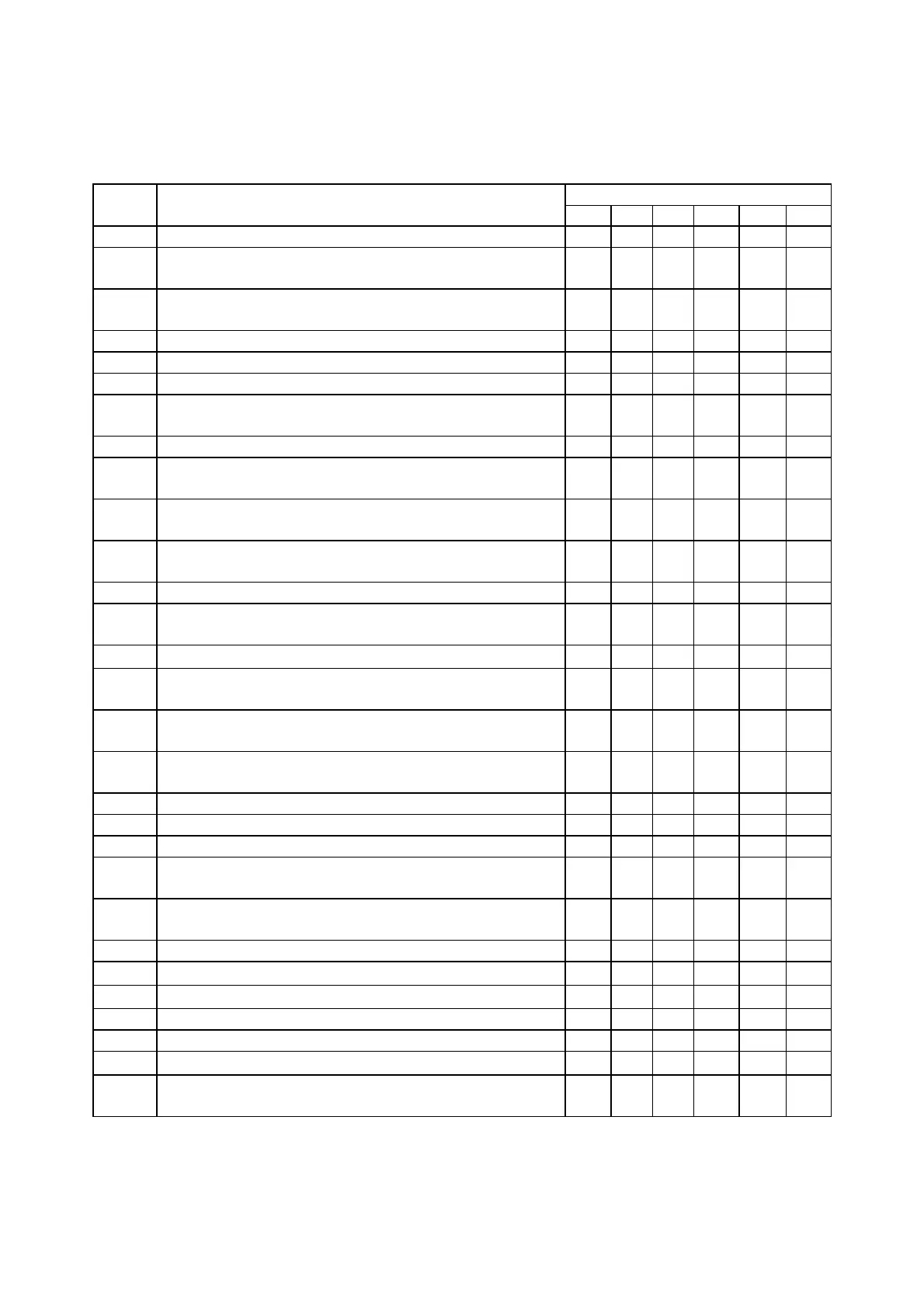

6.3 Technical maintenance procedure

Contents of scheduled technical maintenance operations for tractors BELARUS-

80.1/82.1/820 in the course of operation are listed in Table 6.3.1.

Table 6.3.1

Opera-

tion No

Operation description

Intervals, h

8-10 125 250 500 1000 2000

1 Check oil level in en

ine crankcase X

2 Check level of coolant in the engine cooling sys-

tem

X

3

1)

Check oil level in combined HLL and HSC tank

in HLL tank

X

4

2)

Check oil level in HLL tank X

5 Check condition of t

res X

6 Inspect components of the h

draulic s

stem X

7 Check condition of the electrical wiring in the

en

ine compartment

X

8 Check/clean water radiator of the en

ine X

9 Check breaks functioning in running order, op-

erabilit

of en

ine, steerin

, li

ht/alarm devices X

10 Drain condensate water from the pneumatic sys-

tem tan

X

11

3)

Check threaded joint torqueing of wheels mount-

in

X X

12 Wash tractor and clean cabin inside Х

13 Check level and condition of oil in the sump of

en

ine air cleane

Х

14

4)

Check oil level in hydraulic power steering body

X

15

5)

Check oil level in bodies of upper bevel pairs of

FDA with bevel wheel

ear

oups.

Х

16 Check oil level in intermediate support of FD

cardan drive Х

17

6) 7)

Grease pivot axis bearing of FDA wheel gear

roups Х

18

8)

Check air pressure in the t

res X

19 Drain sediment from fuel tanks X

20 Drain sediment from coarse fuel filte

X

21 Clean filter cartridges of the filter of cab ventila-

tion and heatin

s

stem X

22 Check condition/tension of drive belt for engine

coolin

s

stem fan. X

23

9)

Carr

out accumulator batter

maintenance X

24

Check/adjust gaps in steering joints

X

25 Check/ad

ust toe-in of front wheels

X

26

6) 10)

Grease HSC h

draulic c

linders hin

ed

oints X

27

6)

Grease the bearin

of couplin

clutch shifte

X

28 Check/adjust free travel of clutch pedal

X

29 Change oil filter or clean the rotor of centrifugal

oil filter of the en

ine X

Loading...

Loading...