80-0000010B OM

316

6.4.5 Technical maintenance every 1000 hours of operation

6.4.5.1 General instructions

Perform the previous operations, as well as the operations listed in this subsec-

tion 6.4.5.

6.4.5.2 Operation 49. Check of axial play and adjustment of taper bearings of wheel

flange

Note – The operation shall be performed on tractors BELARUS-820.

With the help of an indicator, check the axial play in taper bearings 9, 10 (Figure

6.4.37) by measuring the shift of flange 11.

Taper bearings shall have no axial play. If it is detected, adjust the bearings as fol-

lows:

- unscrew the bolts and remove the cover that closes nut 8 (Figure 6.4.37);

- tighten the nut with the torque from 180 to 200 Nꞏm, then deflect to the angle of 15

to 20

0

. When tightening the nut, it is necessary to turn through flange 11, so that the bear-

ing’s rollers take the correct position in the cages;

- after the adjustment, punch the nut collar into the two slots of flange. Angular shift

if the nut is not allowed.

6.4.5.3 Operation 50. Oil change in combined tank of HLL and HSC (in HLL tank)

Note – The operation shall be performed for tractors with universal cabin (with can-

opy frame or canopy base on the basis of universal cabin)

Before oil change, heat up the oil in the hydraulic system of HLL and HSC (HLL) to

reach the normal operating temperature by starting the engine and setting any of the lev-

ers of hydraulic outlet control to the “Uplift” position and keeping the lever in such position

until the hydraulic system is heated.

To change oil in hydraulic systems of RLL and HSC, do the following:

- put the tractor on a flat ground, raise the RLL links to their top position, brake the tractor

using the parking brake. The engine shall be stopped;

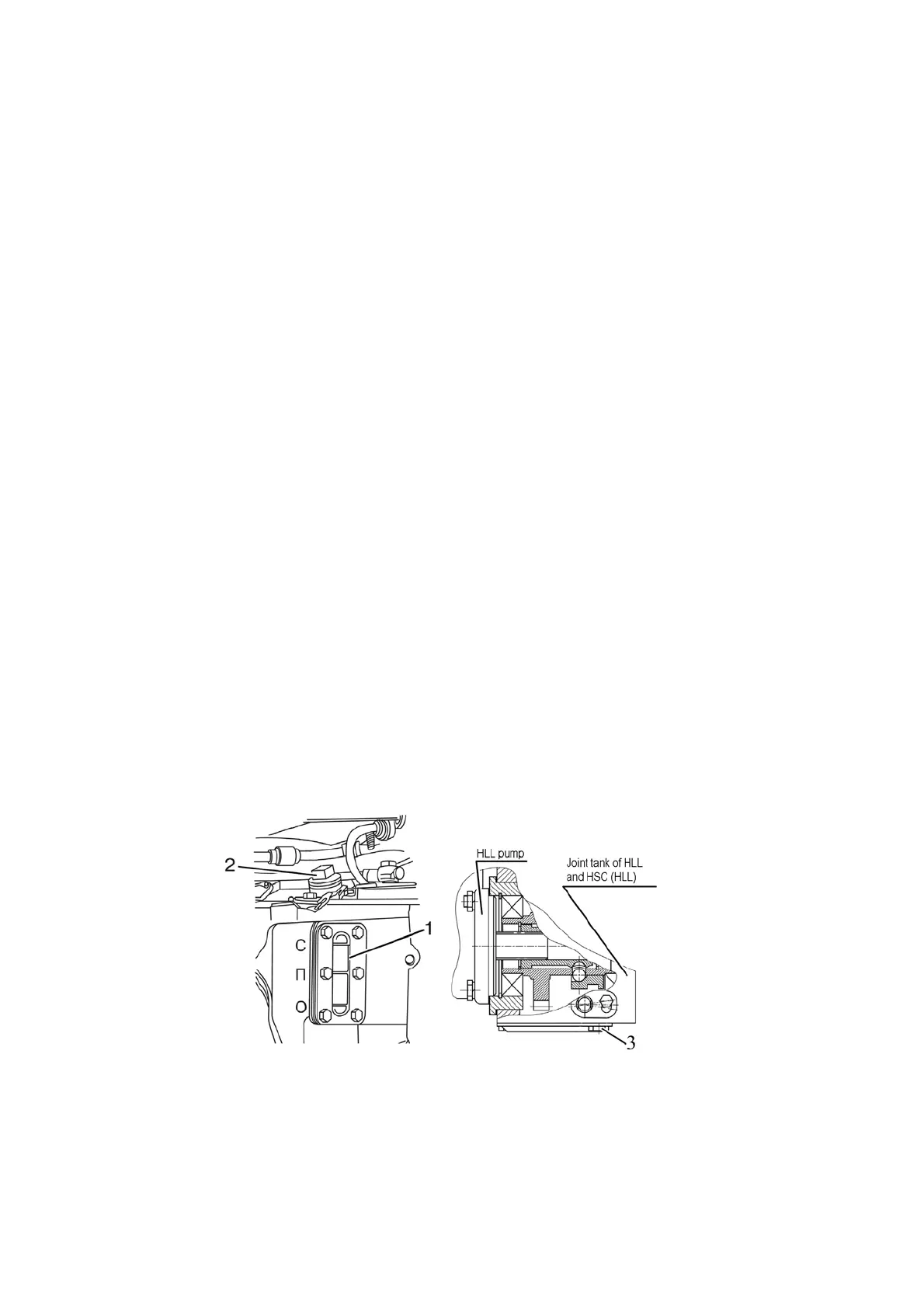

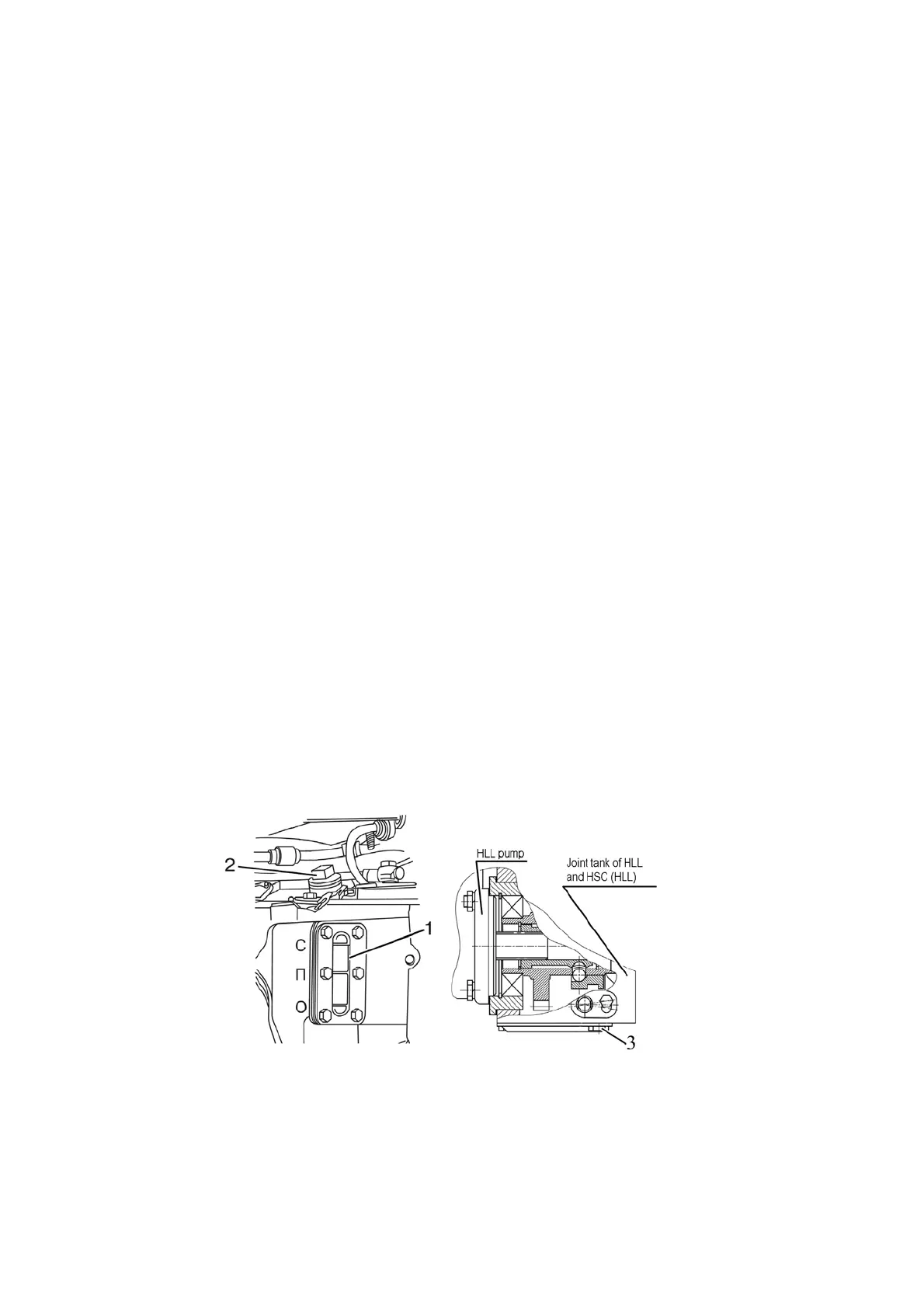

- unscrew the plug of oil filler opening 2 (Figure 6.4.40) and drain plug 3; drain the oil

from the oil tank into a special container for used oil;

- re-place drain plug 3 and fill the system with fresh oil up to the mark “П” on oil level indica-

tor 1. When using machines that require large oil extraction, fill oil to the level of upper mark “С”.

- re-place the plug of oil filler opening 2.

1 – oil level indicator; 2 – plug of oil filler opening; 3 – drain plug.

Figure 6.4.40 – Oil change in hydraulic systems of RLL and HSC

ATTENTION: THE OPERATION OF OIL CHANGE IN HLL AND HSC SHALL BE

PERFORMED ONLY WITH RETRACTED RODS OF RLL HYDRAULIC CYLINDERS AND

OF MACHINES COUPLED WITH THE TRACTOR!

WARNING: BE CAREFUL TO AVOID CONTACT WITH HOT OIL!

Loading...

Loading...