80-0000010B OM

366

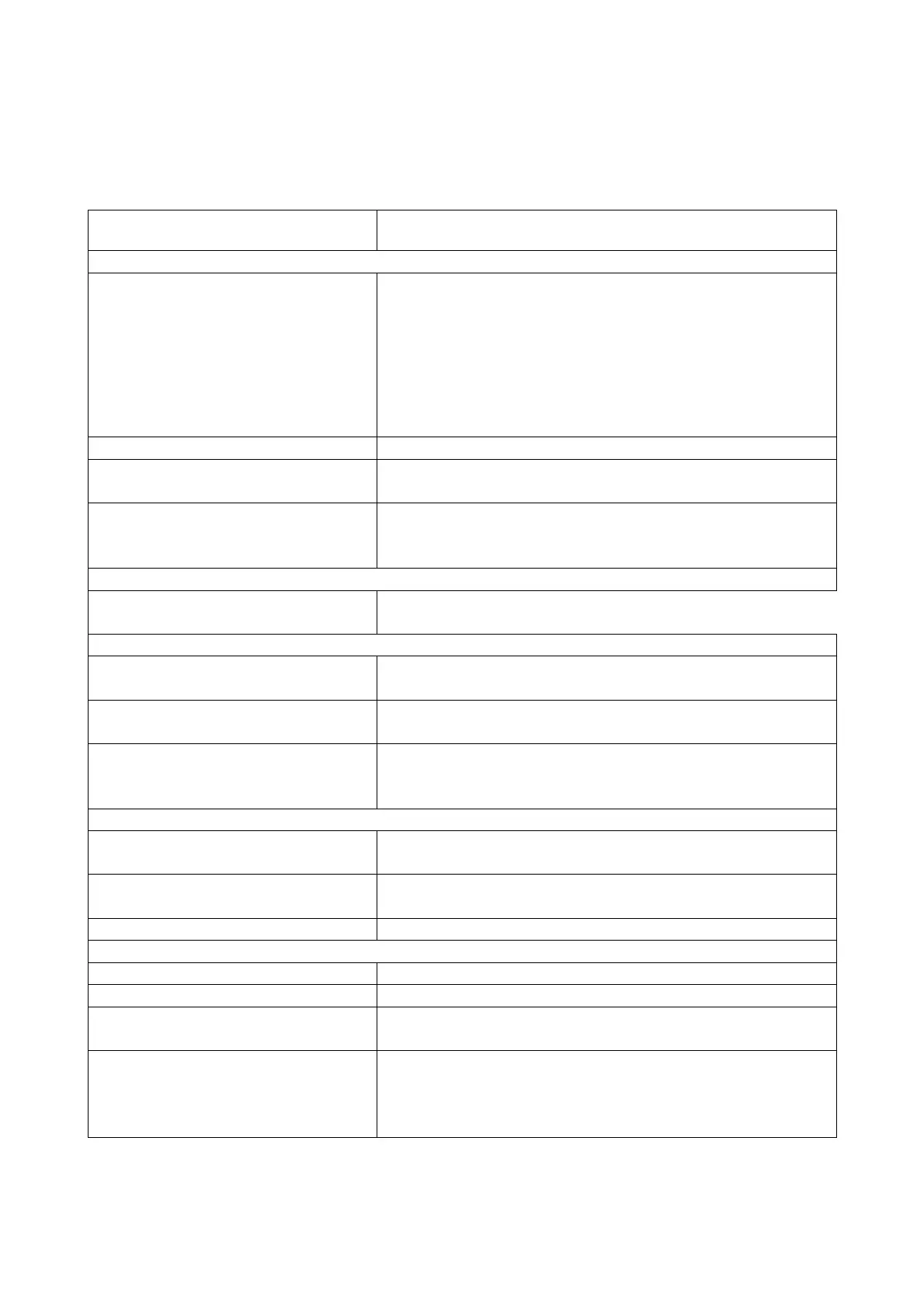

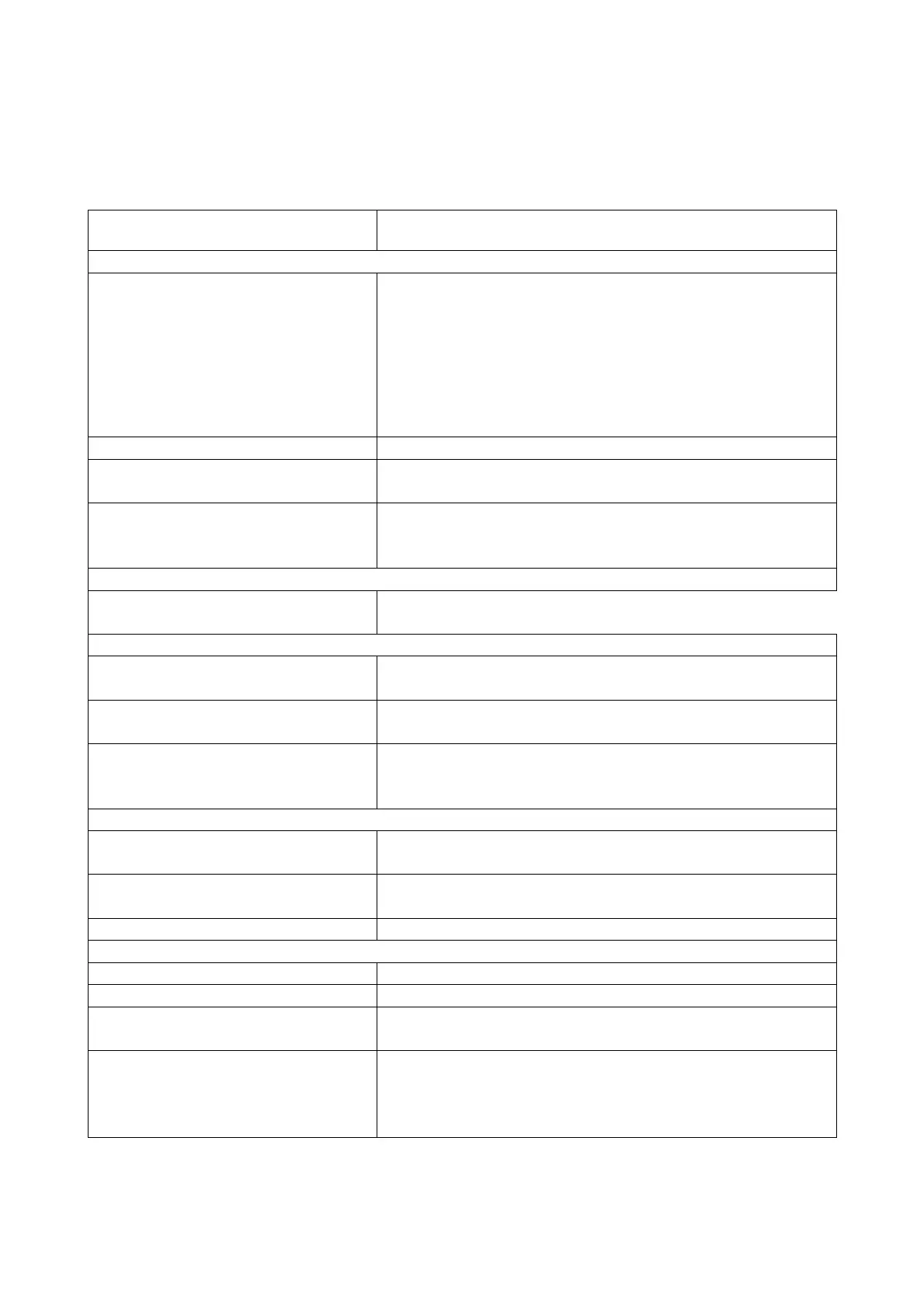

7.12 Possible failures of hydraulic lift linkage and instructions for trouble-

shooting

A list of possible failures of the hydraulic lift linkage and instructions for their trou-

bleshooting are given in Table 7.12.

Table 7.12

Failure,

external manifestation, cause

Troubleshooting

RLL with agricultural implement attached will not rise

No pressure in the hydraulics:

sticking of bypass valve;

Remove the valve parts, rinse and install into the

body. The valve must move freely

clogging of safety valve;

Disassemble the safety valve, rinse, reinstall. Adjust the

valve actuation pressure.

insufficient amount of oil in the

tank.

Add oil to the tank to the recommended level

Loss of pump efficiency Check pump performance, replace if necessary.

Regulator control rod length is

maladjusted

Adjust

Weight of the implement exceeds

the allowable value for the tractor

lift linkage

Use agricultural implements, as agreed with the manu-

facturer

No forced lift linkage lowering

Regulator control rod is improper-

ly adjusted

Adjust

Slow rise of lifting linkage with agricultural implement attached

Air suction into the hydraulic sys-

tem

Identify place of suction and eliminate the failure

Loss of pump performance Check pump performance, replace if necessary.

Weight of the implement exceeds

the allowable value for the tractor

lift linkage

Use agricultural implements, as agreed with the manu-

facturer

Oil foaming in oil tank and spitting through the breather

Air suction into the hydraulic sys-

tem through the suction line

Tighten the connection and replace the gaskets of

suction pipe branch if necessary

Air suction through self-tightening

cuffs of the HLL oil pump

Check condition of self-tightening cuffs and replace if

necessary.

Oil level in the tank is too high Drain excess oil to recommended level.

Increased oil heating during system operation

Insufficient oil in the tank Add oil to the tank to the recommended level.

Oil lines bent or crumpled Repair the crumples or replace oil line

Sticking of spool of hydraulic dis-

tributor

Return the levers of hydraulic distributor to the neutral

position after finishing the operation

Hydraulic motors of the imple-

ment are not in agreement with

the tractor pump feed in terms of

consumption

Apply implements as agreed with the manufacturer

Loading...

Loading...