80-0000010B OM

367

End of Table 7.10

Failure,

external manifestation, cause

Troubleshooting

Agricultural implement will not hold in transport position (lowering speed exceeds

20 mm in 10 minutes

Wrong adjustment of regulator

control rod

Adjust

Oil leak at seal rings of the cylin-

der piston or rod

Replace cylinder piston seal rings

Regulator shut-off valve is not

tight

Adjust or replace the valve

During draft control, the change of ploughing depth exceeds agrotechnical norms,

and en

ine rpm drops at overload

Correction speed valve is shut By turning the flywheel counterclockwise, increase the

speed of automatic corrections

The top link of mounted imple-

ment is installed in the lower hole

of the clevis

Install the top link to the upper hole of the clevis, and if

the maximal ploughing depth is not enough install to the

central hole

Draft sensor is improperly adjust-

ed

Adjust the draft sensor and then the draft link

Draft link is improperly adjusted Adjust the draft link

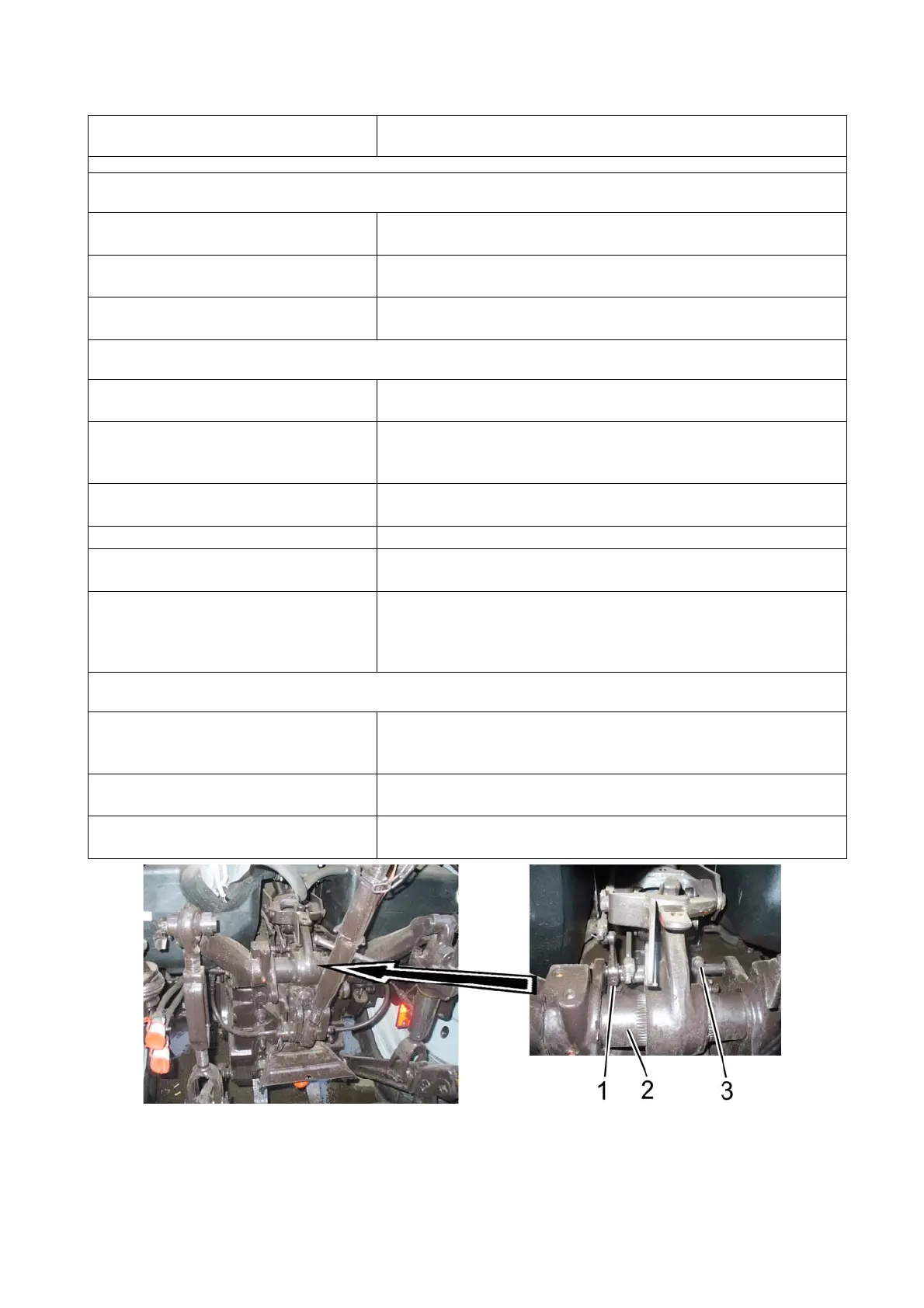

Loosened tightening of split hubs

of levers at intermediate shaft

Tighten bolts 1,3 (figure 7.12.1) of lever hubs on inter-

mediate shaft

Oversized holes on post and

frame of the plough, that are con-

nected with a turnbuckle; insuffi-

cient rigidness of plough frame

Repair the plough so as to provide rigidness of the

frame and its connection to the post

Regulator handle will not return automatically from “Uplift” to “Neutral transport”

position

Jammings in the connections of

control handle with draft regulator

Repair the jammings, strip the surfaces of articulated

joints against corrosion traces, and if necessary apply a

layer of grease

Overtightened bolt of fixer-s

spring on the control handle

Adjust the tension of fixer’s spring at control handle

Wrong adjustment of regulator

control rod

Adjust the length

1,3 – bolts of lever hubs; 2 – RLL shaft

Figure 7.12.1 Tightening the bolts of lever hubs at intermediate shaft

Loading...

Loading...