80-0000010B OM

361

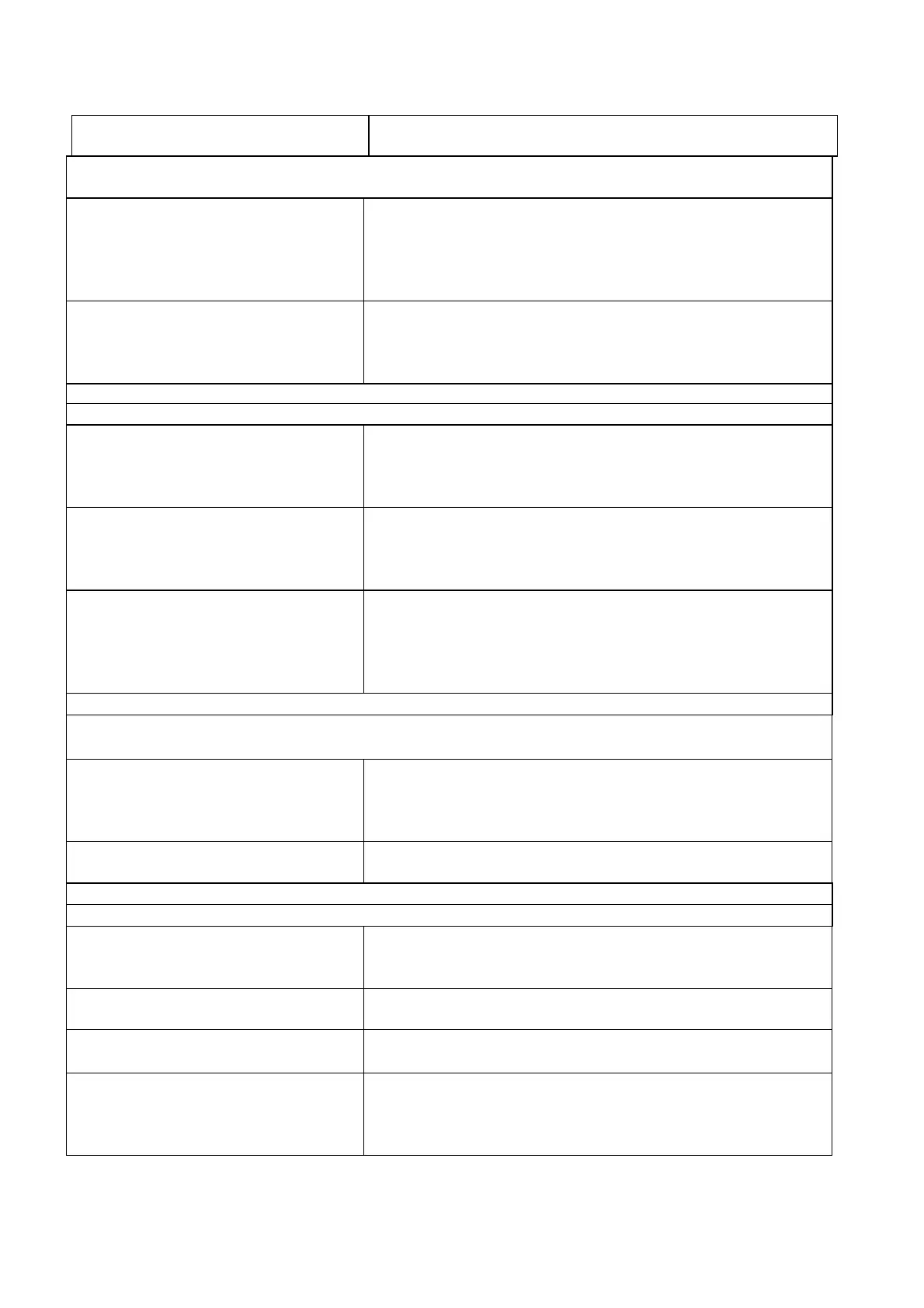

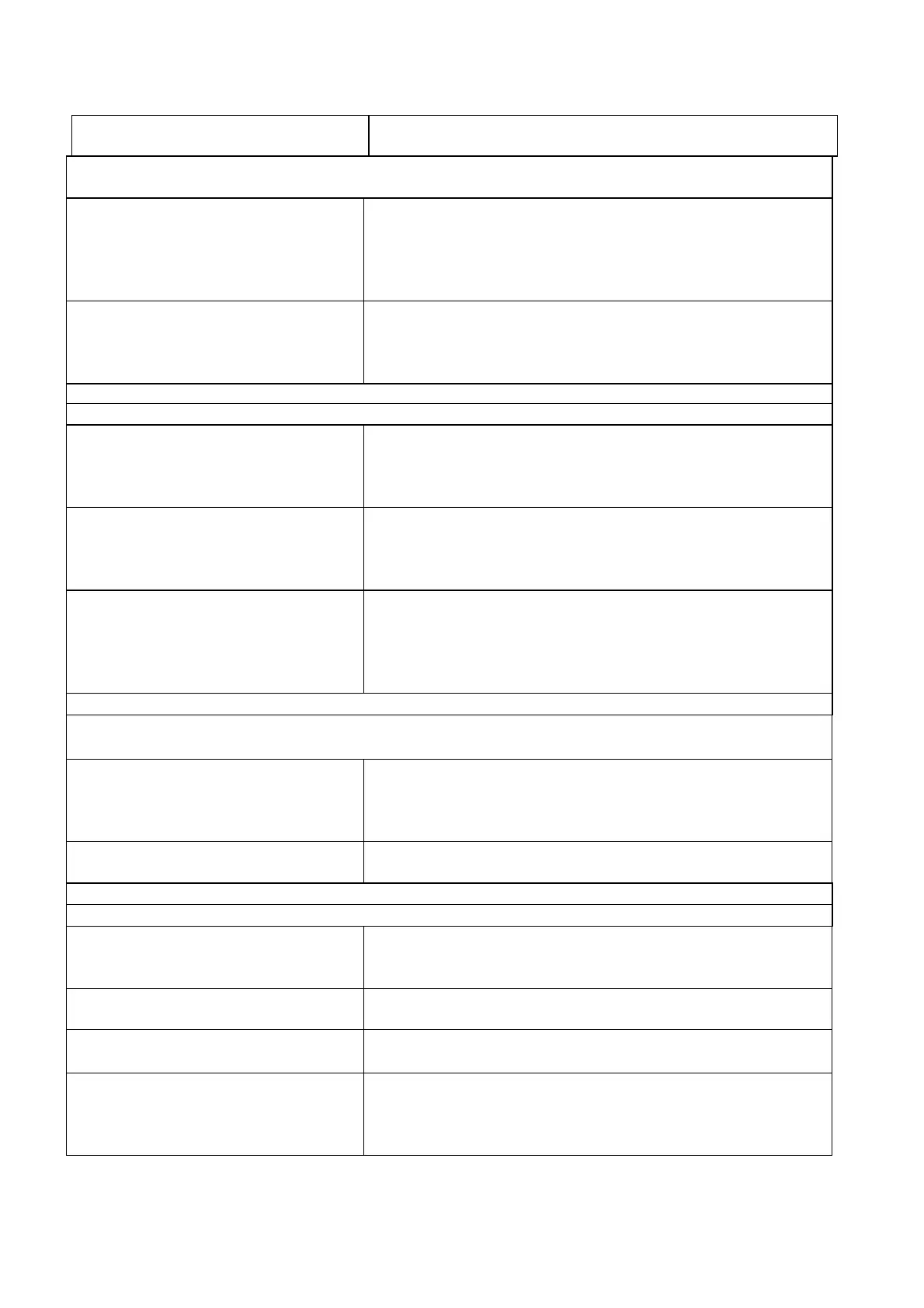

Table 7.9.1 continued

Failure,

external manifestation, cause

Troubleshooting

Steering wheel fails to turn back (by 20…30 mm) when the effort is taken off

the steerin

wheel after turnin

Excessive friction or sticking in

steering column’s mechanical

components

Stop friction in steering column by doing the following:

- loosen upper nut;

- lubricate friction surfaces of plastic bushings;

- eliminate contact of cardan-

oint yoke with steering

column bracket walls.

The springs that return the spool of

dosing pump to the neutral position

have lost their flexibility or are bro-

ken

Contact the dealer. Replacement of springs, assembly

and performance check shall be carried out by the

maintenance department in compliance with the instruc-

tions of the manufacturer

1)

Steerin

wheel

oes on rotatin

after the turn was finished

Gripping of sleeve with the spool

(possible due to dirt accumulation)

Contact the dealer. Rinsing of dosing-pump compo-

nents is required. Assembly and check of operability

shall be performed only by maintenance department in

accordance with manufacturer’s instruction

1)

Spool recentering springs of dos-

ing pump have lost spring flexibility

or are broken

Contact the dealer. Replacement of springs, assembly

and check of operability shall be performed only by

maintenance department in accordance with manufac-

turer’s instruction

1)

The spline drive of the steering

column and the dosing pump are

mounted out-of-line or with an in-

sufficient side clearance

Loosen four bolts retaining the dosing pump on the

steering column. To expand the clearance set max. 1,5

mm thick additional washers between the dosing pump

and the steering column bracket. Tighten the bolts with

a torque of 20 to 25 Nꞏm.

Loss of tightness of dosing pump at spool shaft end, at slot housing

gerotor pair

cover

Worn-out sealing of spool Contact the dealer. Replacement of faulty seals, as-

sembly and check of operability shall be performed

only by maintenance department in accordance with

manufacturer’s instruction

1)

Loosened tightening of doser

cover bolts

Tighten the bolts with the torque of 30 to 35 Nꞏm

Wobblin

o

steered wheel durin

movement

Cone pins of HSC hydraulic cyl-

inders or steering link are not

tightened

Tighten pin nuts

Increased play in steering joints Eliminate play in steering joints as indicated in section 6

“Technical maintenance”

Worn-out mechanical joints or

bearings

Replace worn-out components

Air presence in the HSC hydraulic

system

Bleed air from the HSC hydraulic system by turning

the steering wheel with moving guide wheels from the

left-most to the right-most position (stop-to-stop posi-

tion

for 2-3 times

Loading...

Loading...