1 689 989 212 2014-10-31| Robert Bosch GmbH

Preparation for testing | 1 687 010 496 | 19 en

5. Testing

5.1 Switching on the EPS

Warning - danger of injury due to escaping

test oil or flying parts!

If the hydraulic connections for the test

equipment and common rail pump are set

up incorrectly, test oil can escape at high

pressure or components of the test equip-

ment can burst when the test is started. This

can cause injury or material damage.

¶ Before switching on, check that all hoses

on the test equipment and the common

rail pump are properly connected.

¶ Do not open the splash guard until the

EPS drive motor has stopped.

¶ Replace any leaky or faulty hose lines.

1. On the EPS 815, close the shut-off valve (fig. 3 item

8) of the test oil return.

i Required only on test setup without automatic pres-

sure control.

2. Switch on the EPS at the main switch.

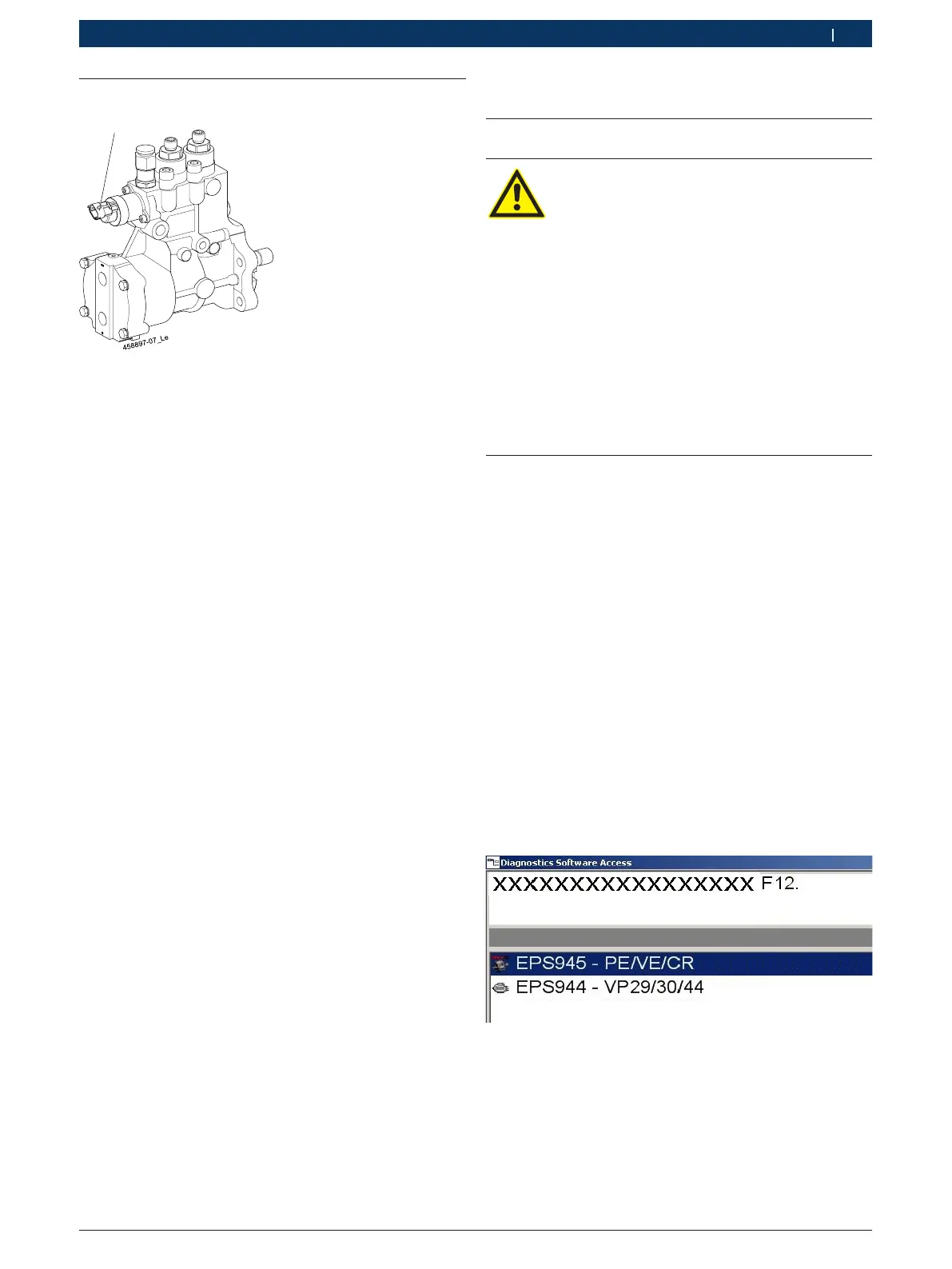

3. Select and start the EPS 945 - PE/VE/CR software

(fig. 6) for the CB18test.

The software performs an initialization and the

status displays light up green.

4. Switch on the converter / test oil pump, the lubricat-

ing-oil supply unit, and the test oil heater at the EPS

control unit.

5. Set the inlet pressure to 0.1 bar – 0.2 bar.

6. Switch on controller release for the drive motor at

the EPS control unit.

" The EPS and CRS 845H test set are ready for the

pump test.

Fig. 6: Software EPS 945 - PE/VE/CR

4.3 Electrically connecting the CB 28

Fig. 5: Electrical connection

1 ZME

¶ Connect ZME connecting line 1684462511 or

1684463706 of the EPS using adapter cable

1684460255 to the ZME (fig.5, item1) of the

CB28.

Loading...

Loading...