1 689 989 212 2014-10-31| Robert Bosch GmbH

Decommissioning | 1 687 010 496 | 21 en

7. Decommissioning

7.1 Change of location

¶ If the 1 687 010 496 is passed on, all the documenta-

tion included in the scope of delivery must be handed

over together with the unit.

¶ The 1 687 010 496 is only ever to be transported in

the original or equivalent packaging.

7.2 Disposal and scrapping

7.2.1 Substances hazardous to water

! Oils and greases as well as refuse containing oil and

grease (e.g. filters) represent a hazard to water.

1. Substances hazardous to water must not be allowed

to enter the sewage system.

2. Substances hazardous to water must be disposed of

in accordance with the applicable regulations.

7.2.2 1 687 010 496 and accessories

¶ Dismantle the 1 687 010 496 and sort out and

dispose of the different materials in accordance with

the applicable regulations.

1 687 010 496, accessories and packaging

should be sorted for environmental-friendly

recycling.

¶ Do not dispose 1 687 010 496 into house-

hold waste.

Only for EC countries:

The 1 687 010 496 is subject to the Euro-

pean directive 2012/19/EC (WEEE).

Dispose of used electrical and electronic

devices, including cables, accessories and

batteries, separately from household waste.

¶ Make use of the local return and collection

systems for disposal.

¶ Proper disposal of 1 687 010 496 prevents

environmental pollution and possible

health hazards.

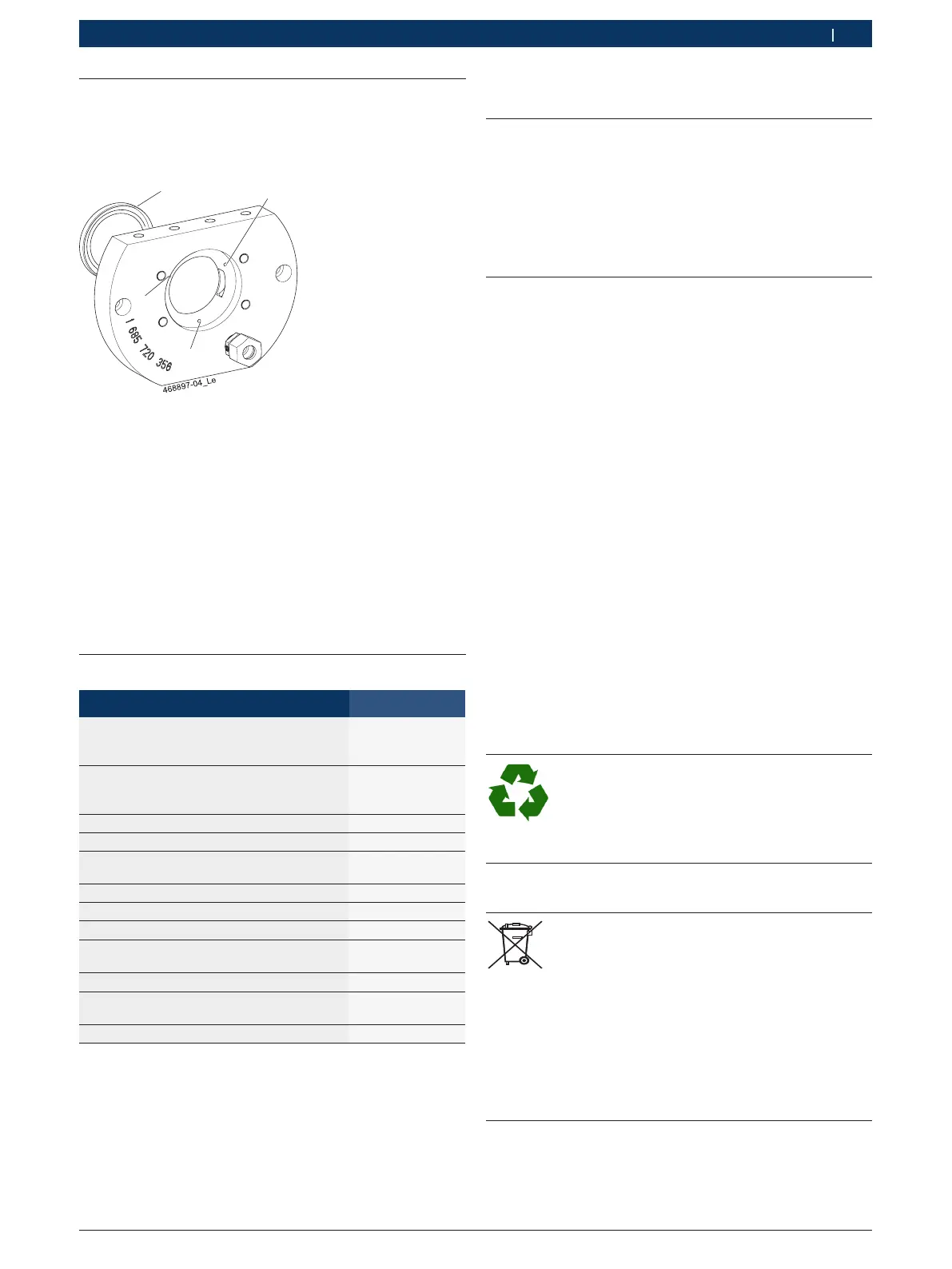

6.4 Replacing radial shaft seal

Replace the radial shaft seal on fixing flange

1685720356, if during a test any damage is detected

to the sealing lip, or leakage is detected.

Fig. 7: Fixing flange with radial shaft seal

1. Using a punch (D = 3 mm) through the 3 bores of

the fixing flange (fig. 7, item 1, 2, 3), drive the radial

shaft seal (fig. 7, item 4) out of its seat

2. Apply a light coat of oil to the new radial shaft seal

and place it flat on the seat of the fixing flange.

3. With a hand press and an assembly tool (e.g. plate

with a flat surface that completely covers the radial

shaft seal), press the radial shaft seal in flush.

4. Press in the radial shaft seal again after waiting 2

minutes.

6.5 Spare and wearing parts

Designation Part number

Fixing flange (for flange D = 85 mm)

R Radial shaft seal (FKM - 60 x 80 x 7)

<)

R Threaded union (G 1/2")

<)

1 685 720 356

1 680 209 032

1 683 391 152

Coupling half (D=24.8, M18 x 1.5)

<)

R Hexagon collar nut (M18 x 1.5)

<)

R O-ring (30 x 3 mm)

<)

1 686 430 059

1 683 314 017

1 680 210 134

Mounting sleeve 1 680 506 040

Mounting wrench 1 687 951 030

Exhaust gas sampling hose

<)

R Plug-in hose nipple (G 1/8")

<)

1 680 712 367

1 684 484 012

Exhaust gas sampling hose

<)

1 680 712 202

Inlet union (M14 x 1.5/ AD15/ 24°)

<)

1 683 385 056

Exhaust gas sampling hose

<)

1 680 712 373

Test adapter

<)

R Plug-in hose nipple (M8 x 1)

<)

0 986 613 091

0 986 613 089

Threaded socket (M10 x 1)

<)

l 1 683 356 133

Inlet union screw (2 x 10 (3-4) DIN

7643-9SMNPB2)

<)

2 911 201 703

Threaded piece (M14 x 1.5 / M16 x 1.5)

<)

2 413 359 003

<)

Wear parts

! Test oil as per ISO 4113 is classified under waste oil

collection category 1. Category 1 waste oil must not

contain any foreign substances, such as waste oils

of a different category, gasoline or diesel. See the

safety data sheet of the test oil for the correct waste

code number.

Loading...

Loading...