2-42 2002 Buell P3: Chassis

HOME

11. See Figure 2-67. Remove the slide bushing by prying the

slide bushing at the split.

CLEANING AND INSPECTION

1. Thoroughly clean and inspect all parts. Replace any

parts that are bent, broken or damaged.

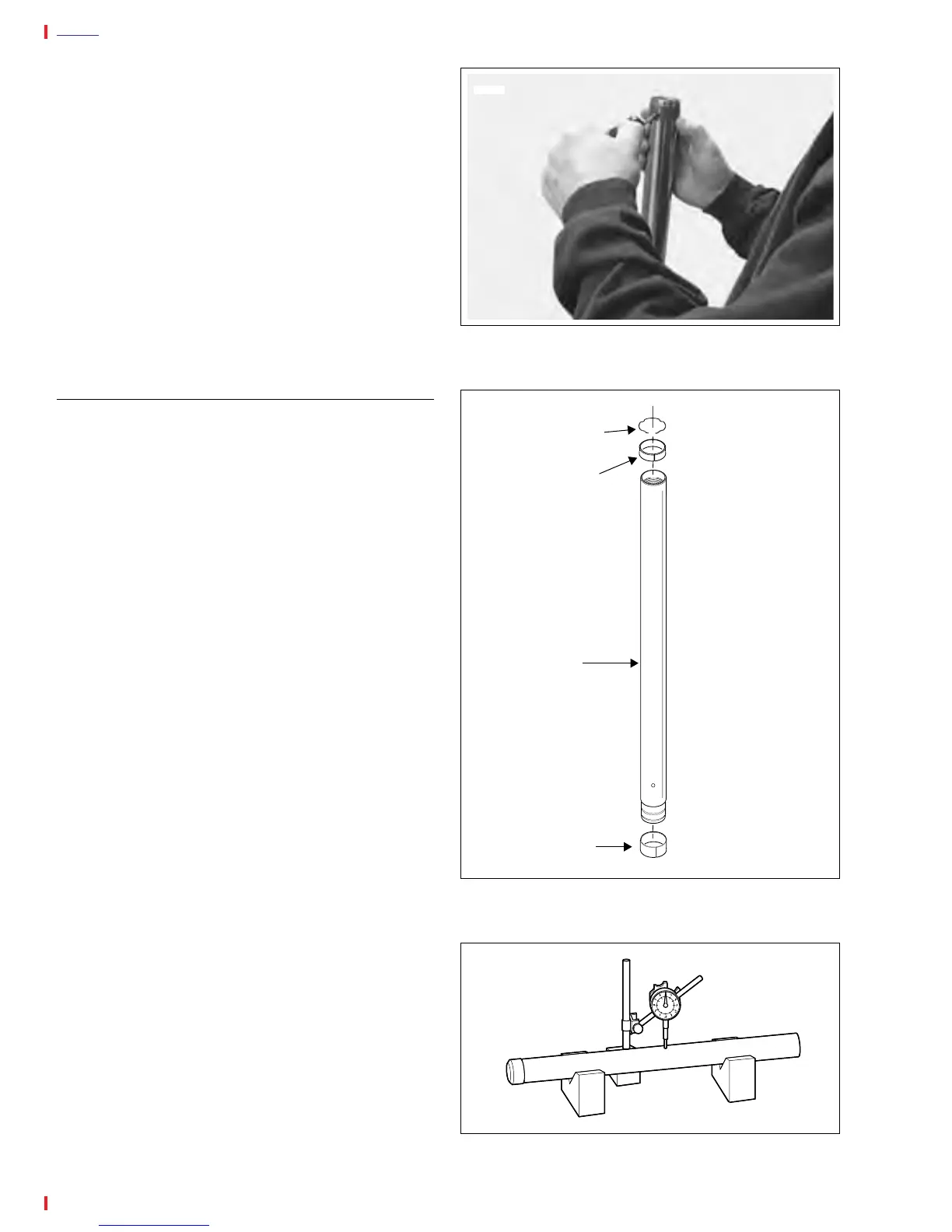

2. See Figure 2-68. Check the slider tube for score marks,

scratches and excessive or abnormal wear. Replace if

worn or damaged.

3. Check the slide bushing and the guide bushing for

excessive wear or scratches. Replace if damaged or

worn.

4. Replace the retaining ring if distorted.

5. Measure spring free length. Replace springs shorter

than service wear limit of 12.8 in. (325 mm).

6. Measure rebound spring free length. Replace springs

shorter than service wear limit of .69 in. (17.4 mm).

7. See Figure 2-69. Measure slide pipe runout. Replace

pipe if runout exceeds the service wear limit of 0.008 in.

(0.2 mm).

Figure 2-67. Removing Slide Bushing

Figure 2-68. Slider tube Components

Figure 2-69. Pipe Runout

3776

a0007xSx

Slide Bushing

Slider Tube

Guide Bushing

Retaining Ring

a0001xSx

Loading...

Loading...