3-62 2002 Buell P3: Engine

HOME

ASSEMBLY/INSTALLATION

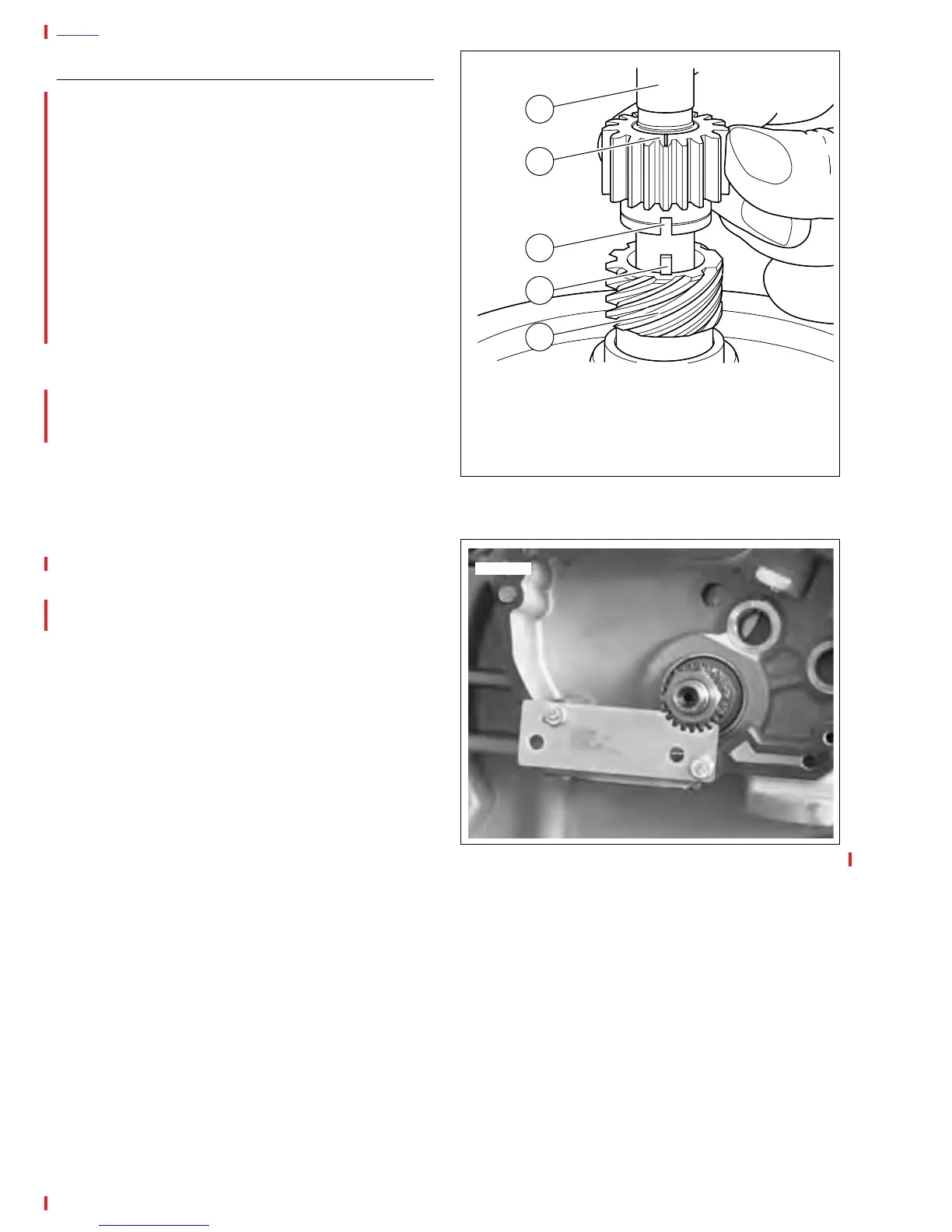

1. See Figure 3-110. Install oil pump drive gear and pinion

gear on pinion shaft.

a. Install shaft key into pinion shaft slot.

b. Slide oil pump gear drive gear over pinion shaft.

Drive gear must align with shaft key.

c. Align keyway in ID of pinion gear with shaft key.

d. Slide pinion gear over shaft key and against oil

pump drive gear.

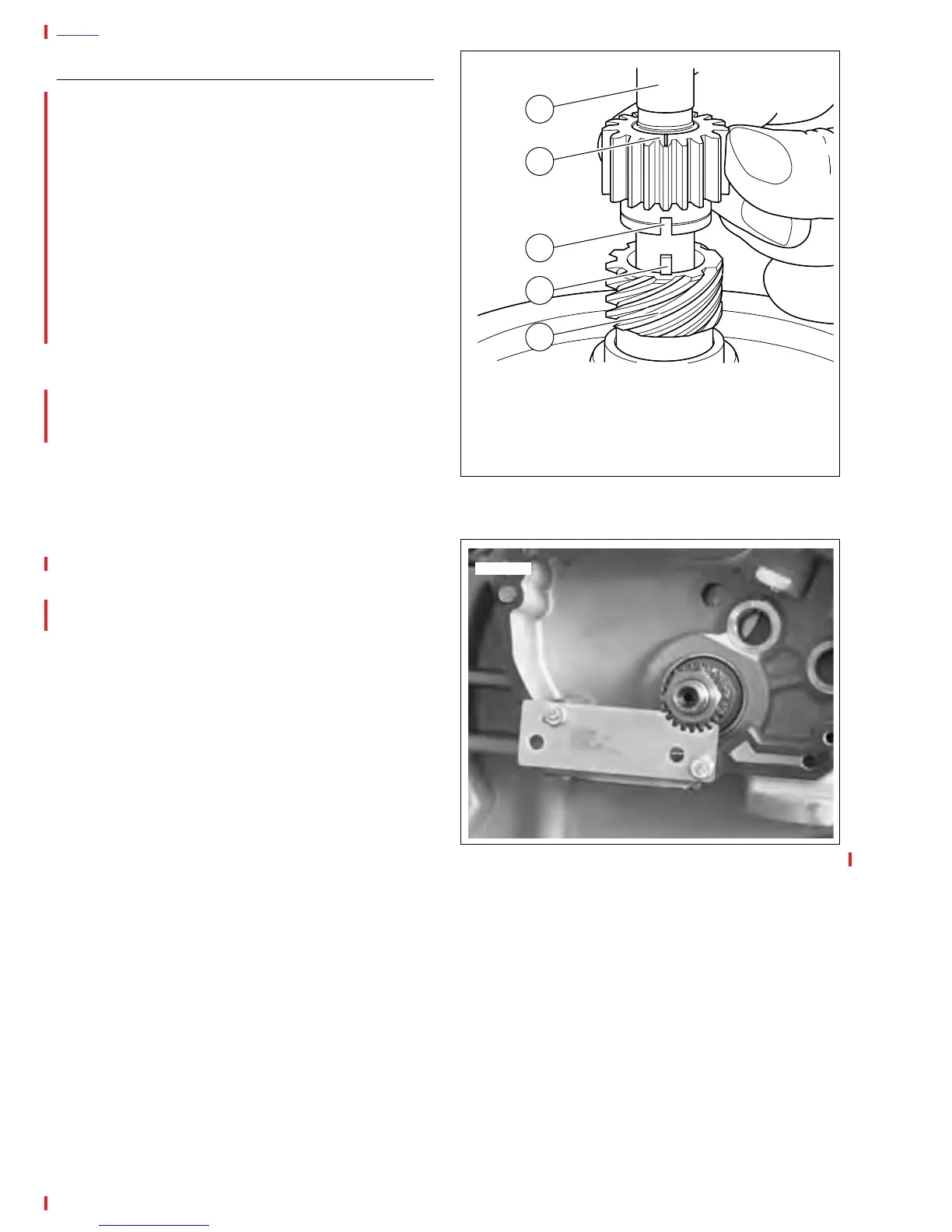

2. See Figure 3-98. Install nut.

a. Clean threads on pinion shaft and nut.

b. See Figure 3-111. Install CRANKSHAFT LOCKING

TOOL (Part No. HD-43984) to gearcase with “Side

B” facing out, over pinion shaft, with two screws.

c. Apply several drops of LOCTITE

®

thread locker 262

(red) to last few threads of nut.

d. Install nut to pinion shaft. Tighten nut to 19-21 ft-lbs

(26-29 Nm) plus an additional 15 to 17 rotation.

3. See Figure 3-101. Liberally apply engine oil to bushings,

shafts, and gears. Install all cam gears into bushings of

right crankcase half, properly aligning timing marks of

cam gears and pinion gear.

NOTE

Because of the larger diameter additional gear (which

meshes with the pinion gear) on the outboard end of the cam,

the exhaust cam gear must be installed before the intake cam

gear is installed.

4. See Figure 3-98. Install a new seal and new dry gear-

cover gasket on crankcase.

°

°

Figure 3-110. Aligning Pinion Gear

Figure 3-111. Crankshaft Locking Tool (HD-43984)

1. Pinion Shaft

2. Timing Mark on Pinion Gear

3. Keyway

4. Shaft Key

5. Oil Pump Drive Gear

a0078x3x

1

2

3

4

5

7686

Loading...

Loading...