M-Series Operator’s Manual 4/9/15 11-5

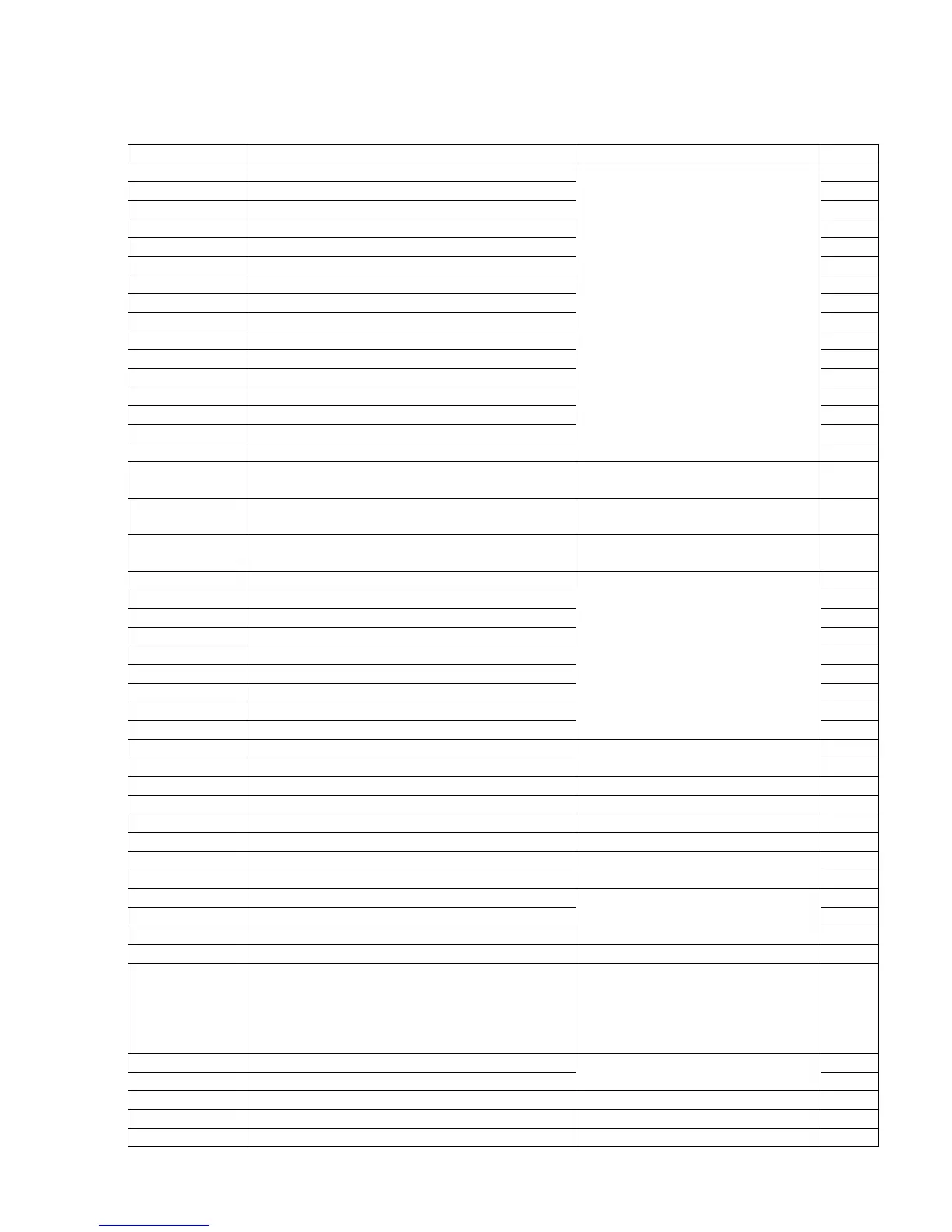

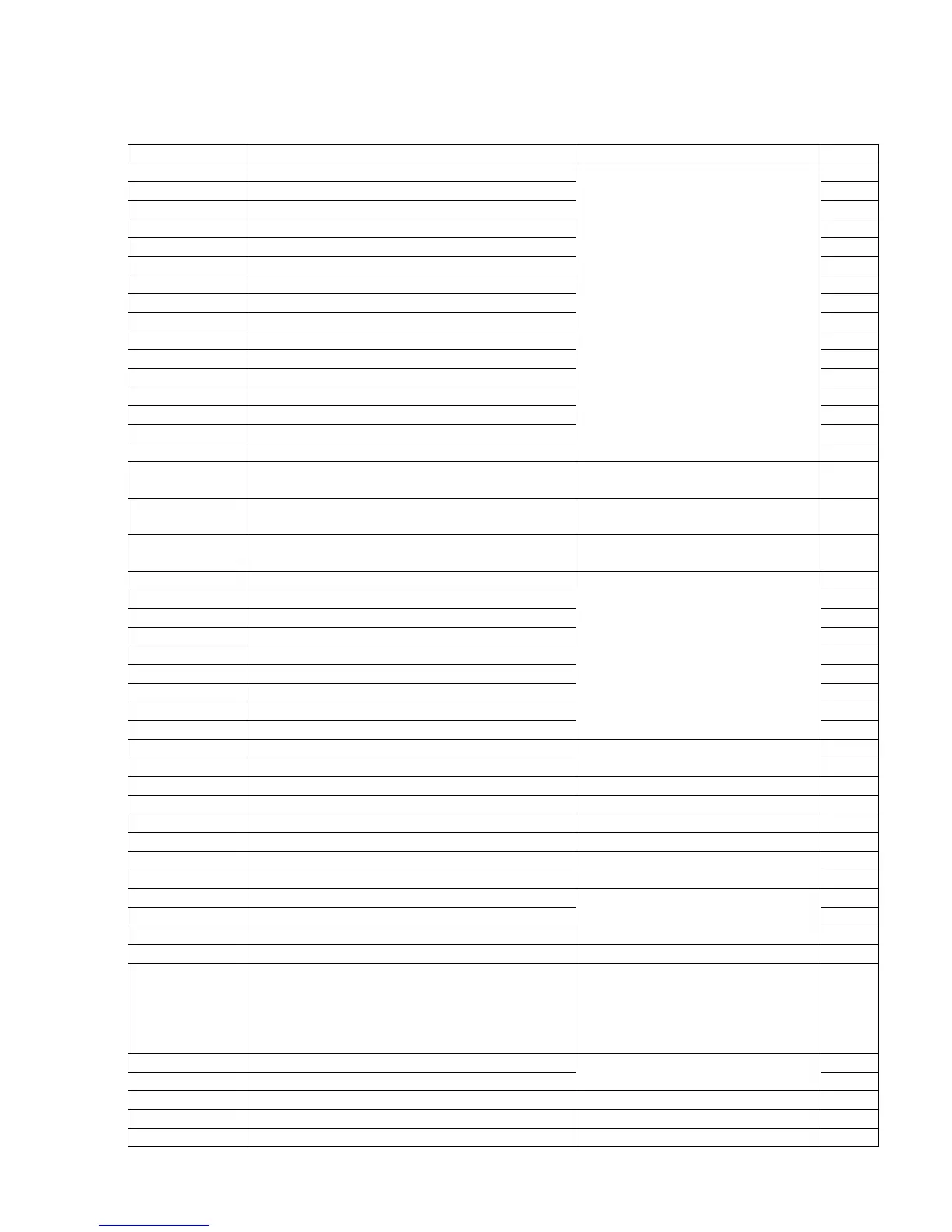

#, = - User or System Variable reference

The ‘#’ character is used to reference a macro or a user or system variable. For variables that can be written, the ‘=’

is used to assign to them. General purpose user variables are #100 to #149 and #29000 to #31999.

Index Description Returns R/W

1-3 Macro arguments A-C R/W

4-6 Macro arguments I-K (1st set) R/W

7-9 Macro arguments D-F or 2nd set of I-K R/W

10 3rd I (G is invalid) R/W

11 Macro argument H or 3rd J R/W

12 3rd K (L is invalid) R/W

13 Macro argument M or 4th I R/W

14 4th J (N is invalid) R/W

15 4th K (O is invalid) R/W

16 5th I (P is invalid) R/W

17-18 Macro argument Q-R or 5th J-K R/W

19-21 Macro arguments S,T,U or 6th set of I-K R/W

22-24 Macro arguments V,W,X or 7th set of I-K R/W

25-27 Macro arguments Y,Z or 8th set of I-K R/W

28-30 9th set of I-K R/W

31-33 10th set of I-K

The floating point value if defined by

a G65 call, 0.0 otherwise.

These can be used as private, local

variables in any program or

subprogram except in custom macro

M functions. In custom macro M

functions, the macro arguments are

passed in by reference.

R/W

100 - 149 User variables Floating-point value. Initialized to

0.0 at start of job processing

R/W

150 – 159 Nonvolatile user variables Floating-point value saved in

cncm.job.xml file.

R/W

300-399 User string variables. These variables retain their

values until the CNC software is exited

String Literal R/W

2400, 2401-2418

Active WCS, WCS #1-18 CSR angles R/W

2500, 2501-2518

Active WCS, WCS #1-18 Axis 1 values R/W

2600, 2601-2618

Active WCS, WCS #1-18 Axis 2 values R/W

2700, 2701-2718

Active WCS, WCS #1-18 Axis 3 values R/W

2800, 2801-2818

Active WCS, WCS #1-18 Axis 4 values R/W

2900, 2901-2918

Active WCS, WCS #1-18 Axis 5 values R/W

3000, 3001-3018

Active WCS, WCS #1-18 Axis 6 values R/W

3100, 3101-3118

Active WCS, WCS #1-18 Axis 7 values R/W

3200, 3201-3218

Active WCS, WCS #1-18 Axis 8 values

Floating point value

R/W

3901 Parts Cut (Part #) R/W

3902 Parts Required (Part Cnt)

R/W

4001 Move mode 0.0 (rapid) or 1.0 (feed) R

4003 Positioning mode 90.0 (abs) or 91.0 (inc) R

4006 Units of measure 20.0 (inches) or 21.0 (metric) R

4014 WCS 54.0-71.0 (WCS#1-18) R

4109 Feedrate (F) R

4119 Spindle Speed (S)

Floating point value

R

4120 Tool Number (T) R

4121 Current height offset number (H) R

4122 Current diameter offset number (D, mill only)

R

4201 Job processing state 0 = normal, 1 = graph R

4202 Job Search mode 0 = search mode off

1 = searching for line number

2 = searching for block number N__

3 = searching for Tool number

4 = resuming job

R

5021-5028 Machine Position (X=5021, Y=5022, etc.) R

5041-5048 Current Position (X=5041, Y=5042, etc.)

Floating point value

R

9000-9399 Parameter values 0 – 399 See Chapter 14 R

9900-9999 Parameter values 900 – 999 See Chapter 14 R

10000 Mill: Height offset amount, active H Floating point value R/W

Loading...

Loading...