M-Series Operator’s Manual 4/9/15

Summary

Rigid tapping parameters will vary from machine to machine. Not all machines are built the same (i.e.

Spindle hp, inverter type, rigidity, etc.), and tooling will play a roll in performance also. It was found through

our testing, if we changed one physical parameter, (i.e. using a tapping oil instead of water base coolant), it

improved the off target values by 1.5%. This is due to the fact that less friction is present when using special

cutting oil, therefore requiring less hp by the spindle to drive the tap. In most cases, rigid tapping depths

should be able to be held within +/- .008 inch or less by adjusting parameter 82 for specific cases.

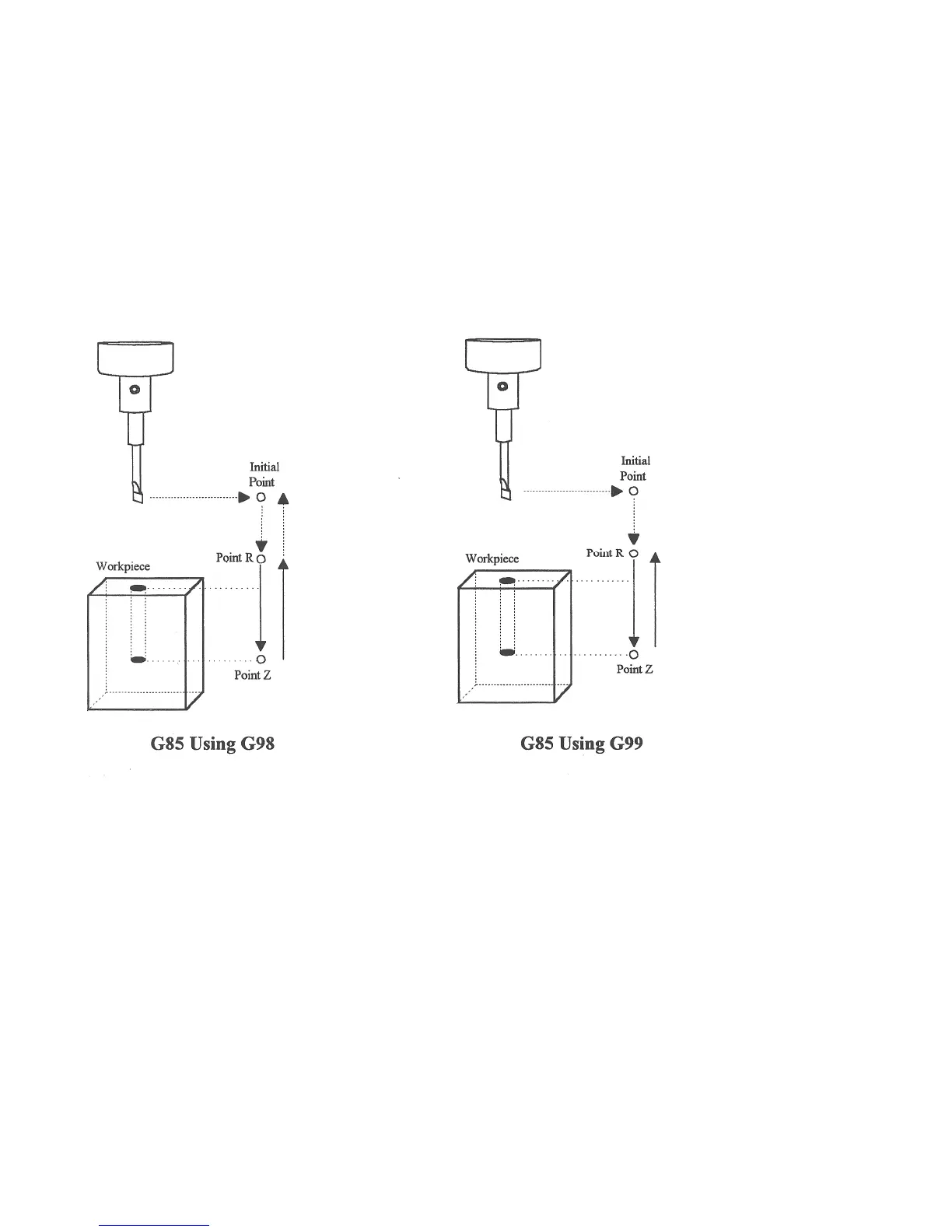

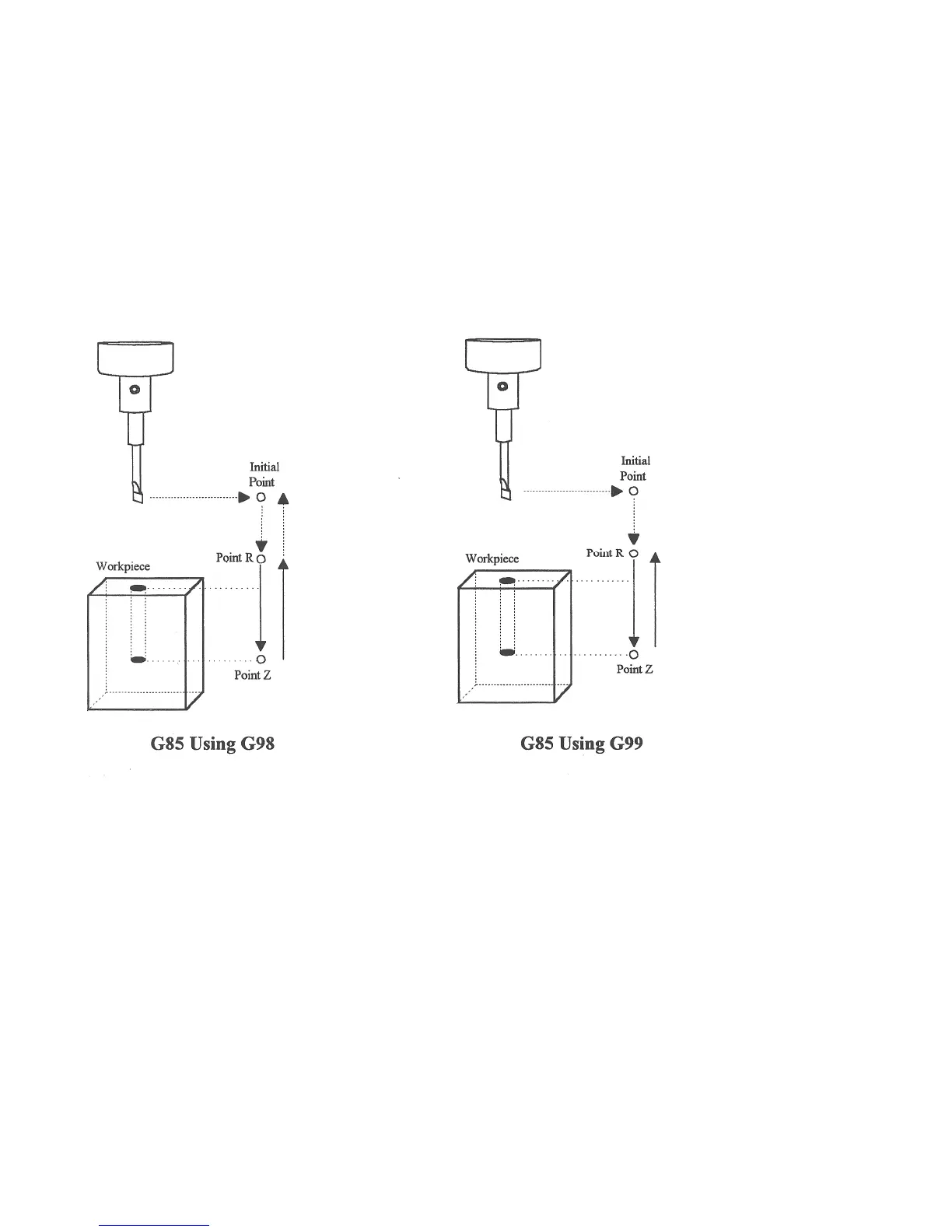

G85 – Boring

G85 is similar to G81, except that the tool is retracted with a feedrate move instead of a rapid move. G85 may be

used for tapping with reversing tap heads such as the Tapmatic NCR series.

Example 1:

G85 X1 Y1 R.1 Z-.5 ; bore a 0.5" hole at X1 Y1

G80 ; cancel canned cycle

Example 2:

M3 S500 F27.78 ; start spindle CW, set for 18 pitch tap

M109/1/2 ; disable feedrate and spindle overrides

G85 X1 Y1 R.1 Z-.4 ; tap hole at X1 Y1 to a depth of 0.4"

M108/1/2 ; enable feedrate and spindle overrides

G80 ; cancel canned cycle

Loading...

Loading...