M-Series Operator’s Manual 4/9/15

List of Rigid tapping setup parameters – see Chapter 14 for more details

Parameter

Function

34 Spindle Encoder Counts/Rev

35 Spindle Encoder Axis Number

36 Rigid Tapping Enable/Disable

37 Spindle Deceleration Time

68 Minimum Rigid Tapping Spindle Speed

69 Duration For Minimum Spindle Speed

74

M-Function executed at bottom of tapping cycle

84

M-Function executed at return to initial point of tapping cycle

82 Spindle Drift Adjustment

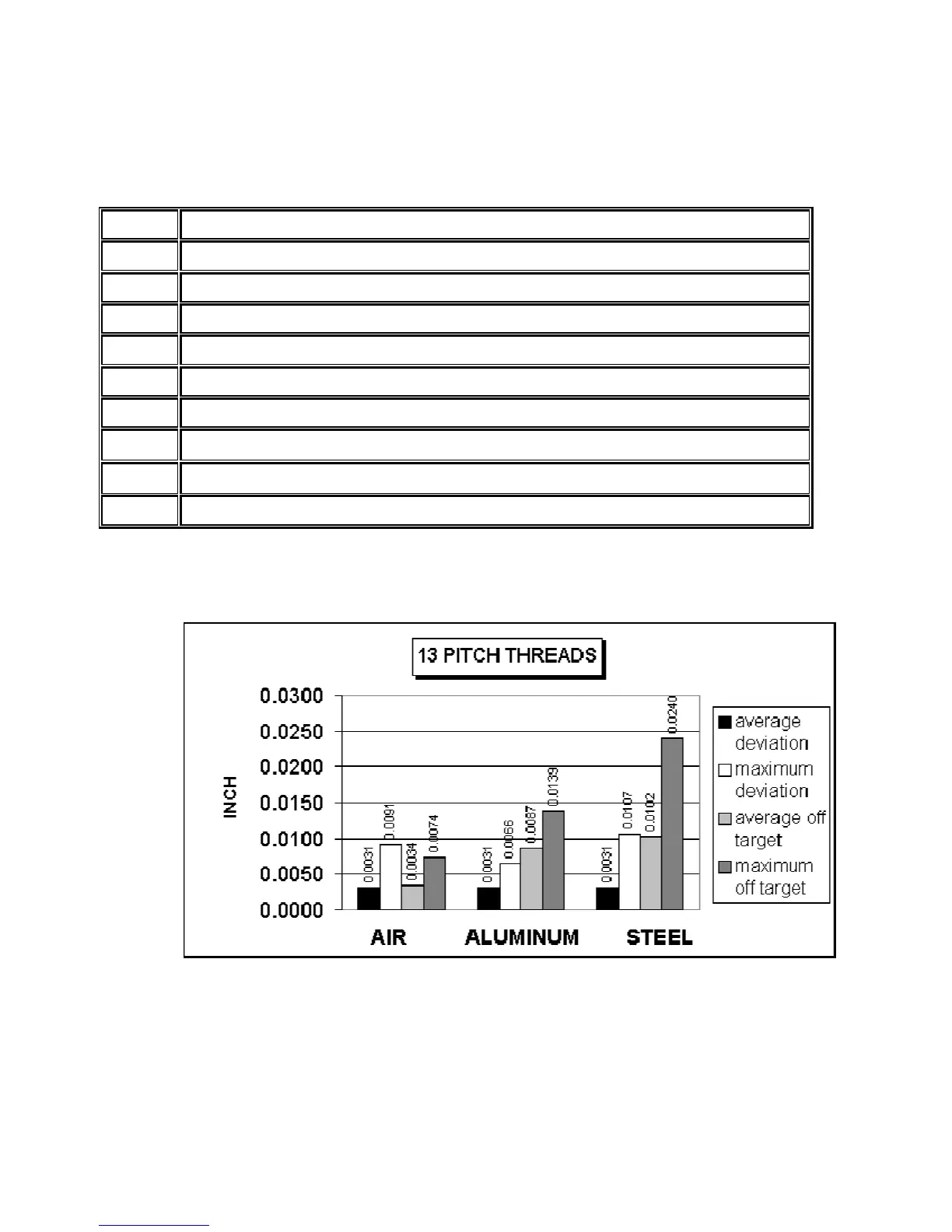

Graphic representation of test results for precision

The above charts show test results of rigid tapping, utilizing version 7.14 software. The tool used in the

testing was a ½-13 spiral fluted tap with TiN coating. Coolant used was water base soluble oil. Hole size was

.4218. Tapping depth was .800. Also note that the parameters were adjusted to cut air, and not changed for

aluminum or cold rolled steel for these tests. It can be seen, as the material changes, so does the off target

values. This is due in part to the amount of torque required from the spindle to cut the various types of

material. For testing purposes, the parameter settings for the above results were as follows.

Parameter 36 = 1, Parameter 37 = 3, Parameter 68 = 100, Parameter 69 = 1.25, Parameter 82 = 108

Loading...

Loading...