M-Series Operator’s Manual 4/9/15

Example:

M3 S500 F27.78 ; start spindle CW, set up for 18 pitch tap

G84 X1 Y1 R.1 Z-.5 ; tap a 0.5 deep hole at X1 Y1

Y1.5 ; ... and another one at X1 Y1.5

G80 ; cancel canned cycle

…

; Using Tool 15 Rigid Tap 6-32

G84 X0.337 Y0.925 Q0.03125 Z-0.35 R0.1 ; tap first hole

G84 X3.312 Y0.925 Q0.03125 Z-0.35 R0.1 ; tap second hole, must use Q

G80 ; cancel canned cycle

…

; Using Tool 22 Rigid Tap 4-40

G84 X1.862 Y1.627 Q0.025 Z-0.19 R0.1 ; tap first hole

G84 X2.862 Y1.627 Q0.025 Z-0.19 R0.1 ; tap second hole, must use Q

G84 X4.262 Y1.627 Q0.025 Z-0.19 R0.1 ; tap third hole, must use Q

G80 ; cancel canned cycle

Tech Tip – How to Setup Rigid Tapping

Overview

This section describes the theory of rigid tapping parameters, to control accuracy of depth of cut and

quality of threads, in various working materials.

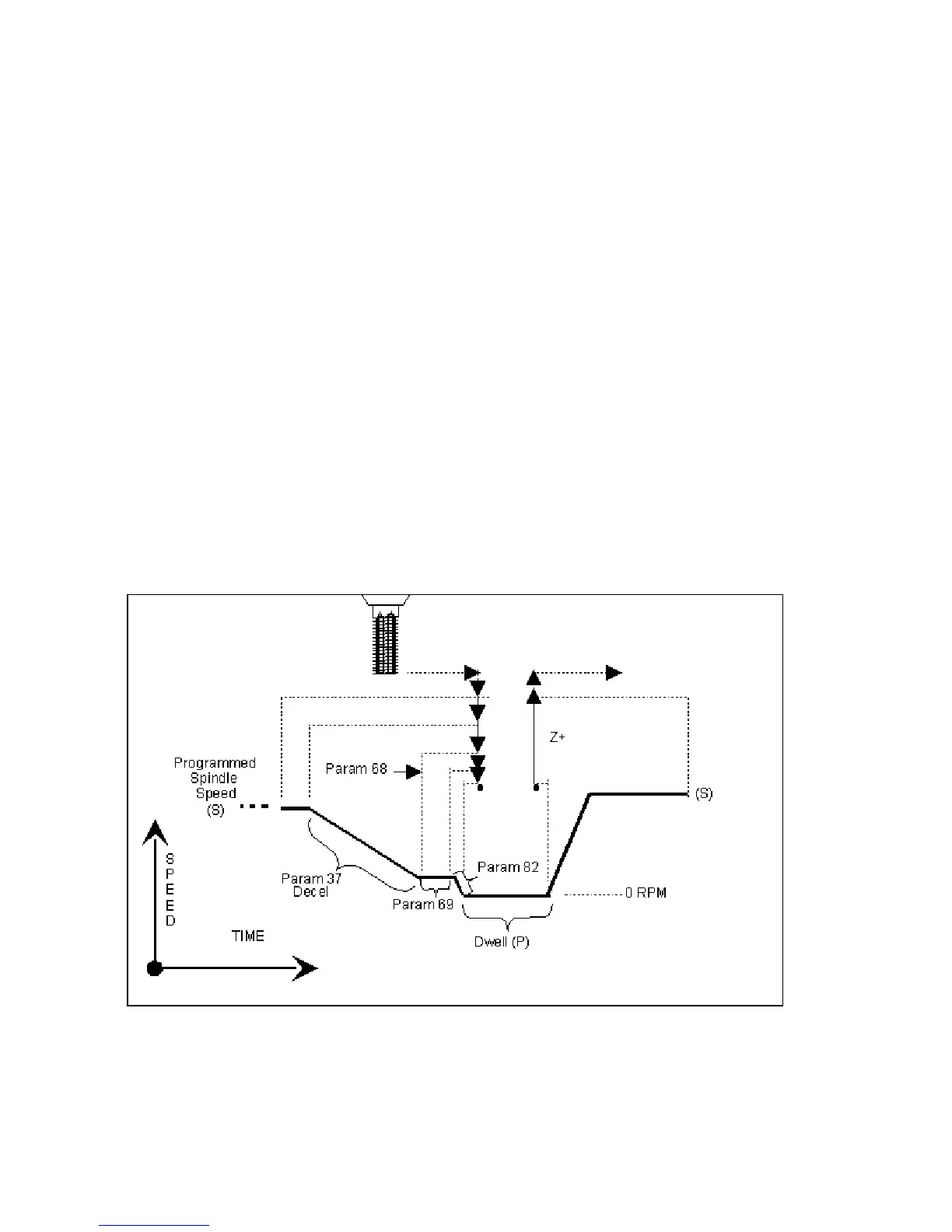

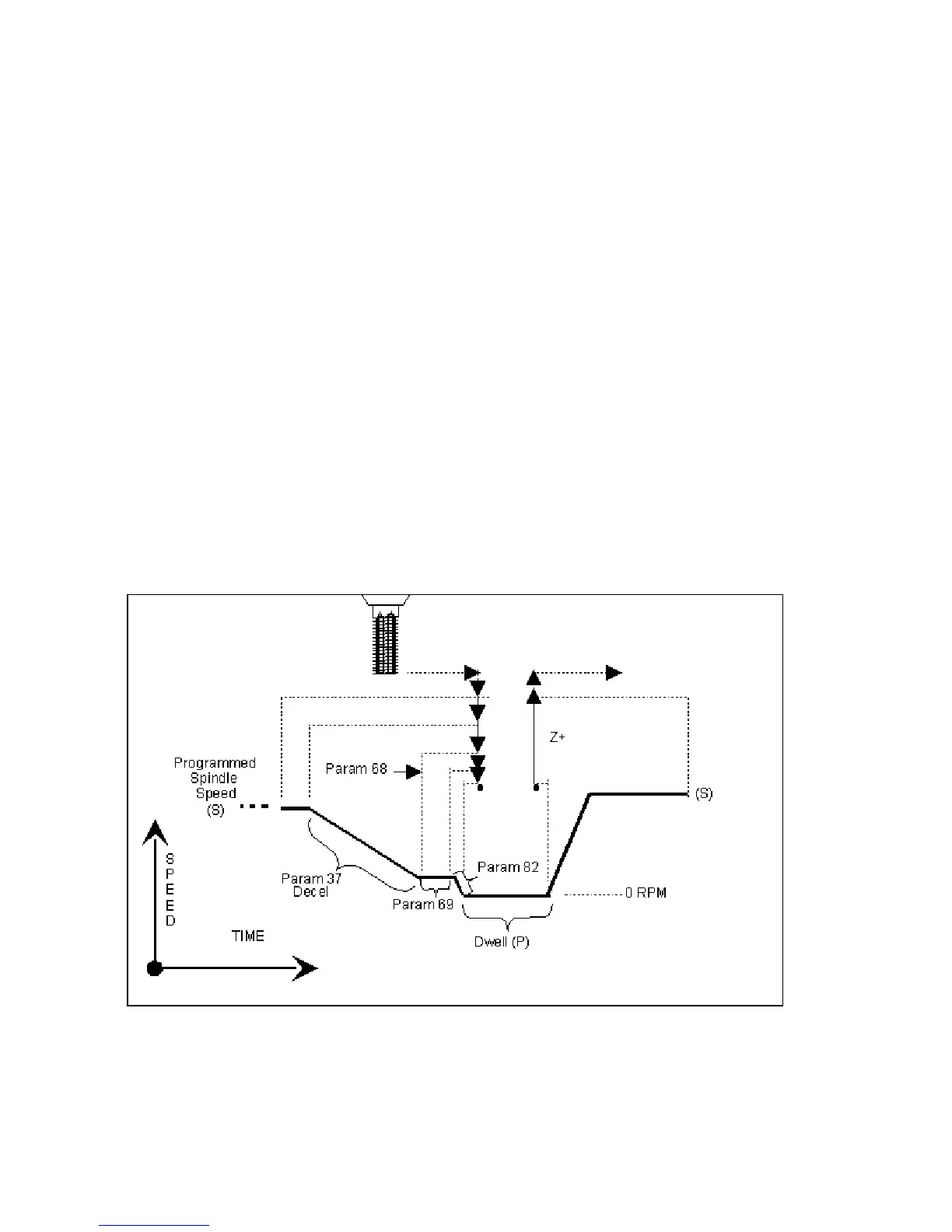

Graphic representation of parameter controls

Loading...

Loading...