M-Series Operator’s Manual 4/9/15

G83 is a deep hole drilling cycle. It periodically retracts the tool to the surface to clear accumulated chips, then

returns to resume drilling where it left off. The retract and return are performed at the rapid rate. Because there

may be chips in the bottom of the hole, the tool does not return all the way to the bottom at the rapid rate. Instead it

slows to feedrate a short distance above the bottom. This clearance distance is selected by setting Parameter 83

with G10 (see example below).

Example:

G10 P83 R.05 ; set clearance to .05"

G83 X0 Y0 R.1 Z-2 Q.5 ; drill 2" deep hole in 0.5" steps

G80 ; cancel canned cycle

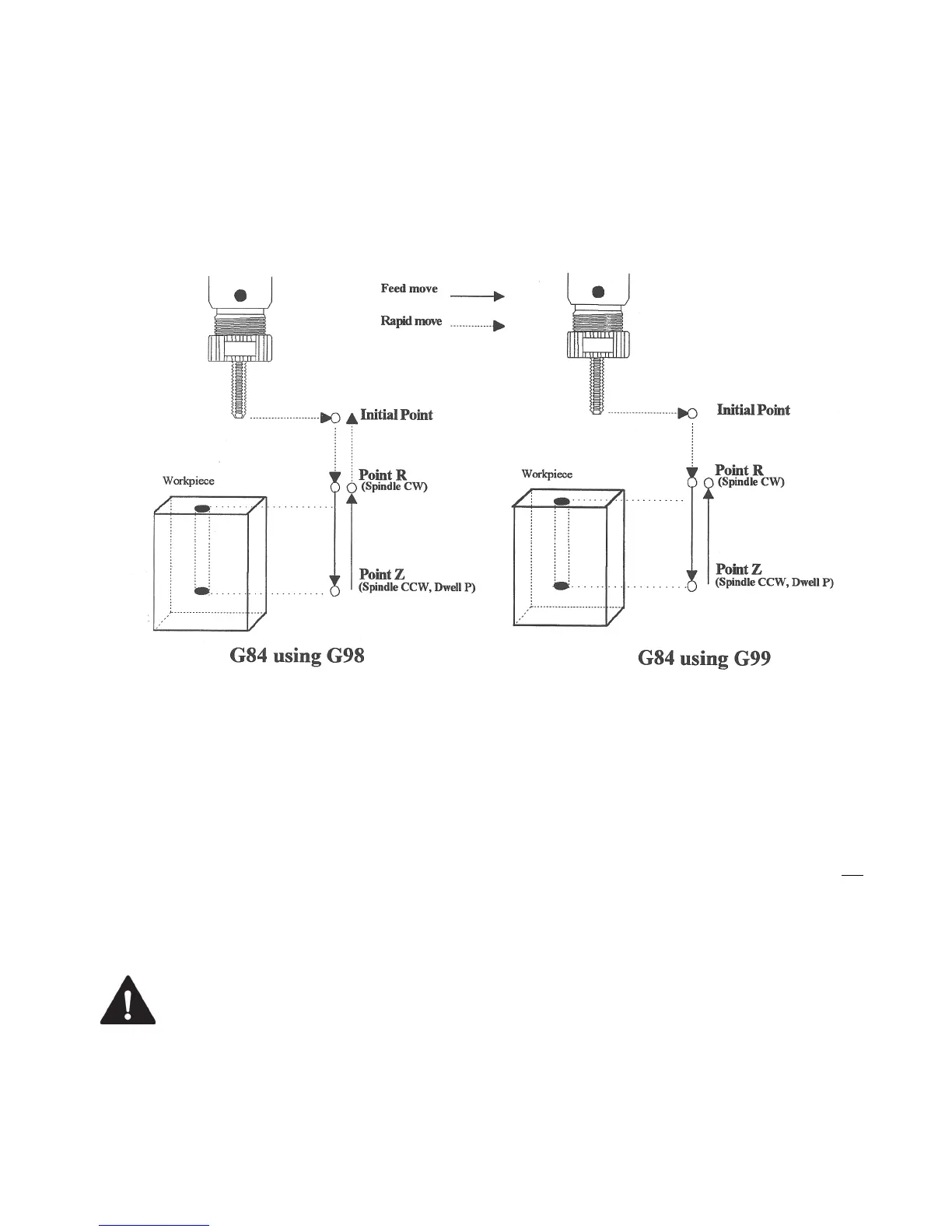

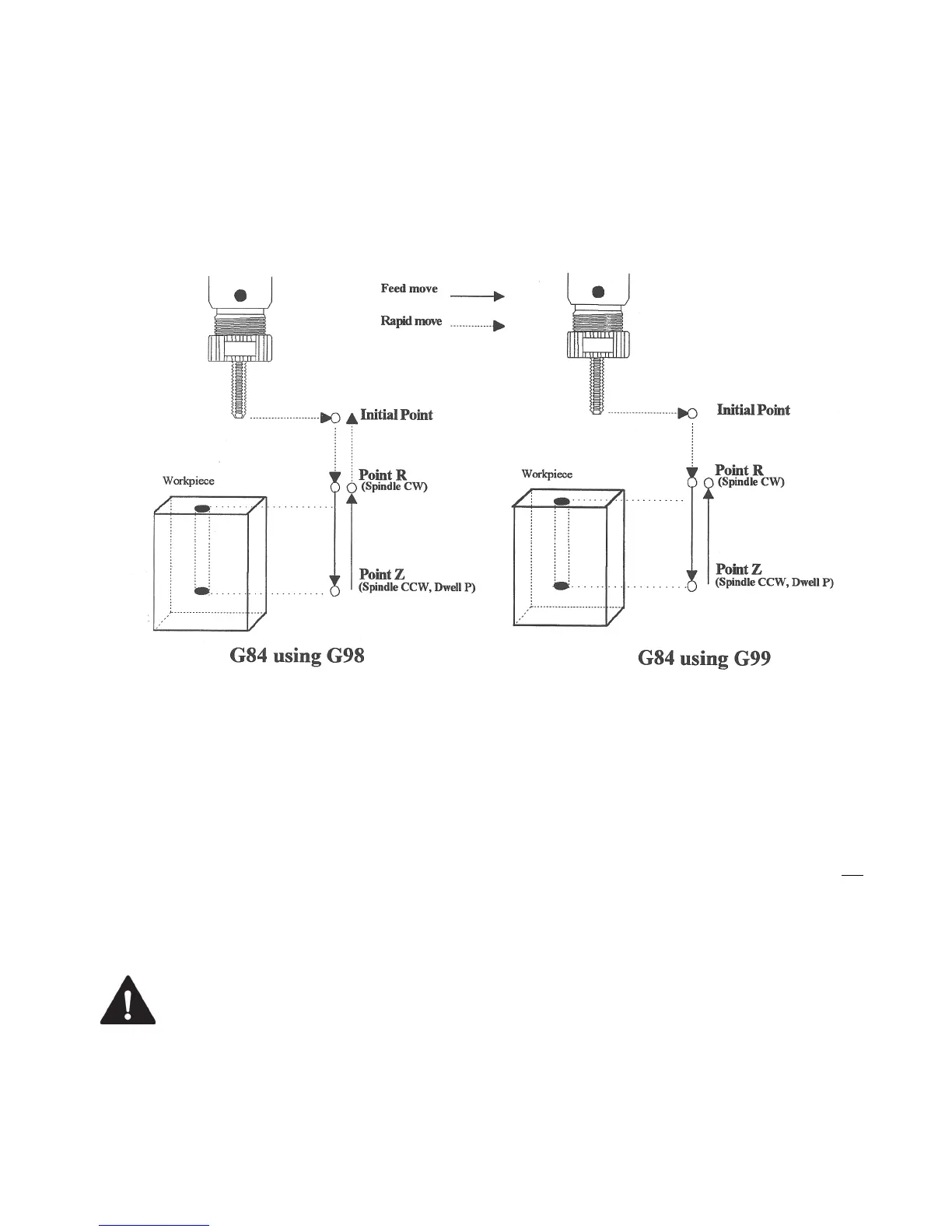

G84 - Tapping

G84 performs right-hand tapping. The spindle speed (and feedrate, if you are doing floating tapping) should be set

and the spindle started in the CW direction before issuing G84. G84 will normally use the default M4 to select

spindle CCW (at the bottom of the hole) and M3 to re-select spindle CW (after backing out of the hole) depending

on the settings of parameters 74 and 84.

The tap may continue to cut a short distance beyond the programmed Z height as the spindle comes to a stop before

reversing. When tapping blind holes, be sure to specify a Z height slightly above the bottom of the hole to prevent

the tool from reaching bottom before the spindle stops.

Note: If rigid tapping is enabled, a Q may be used to set the thread lead or pitch. However, because Q is not modal

in the case of Rigid Tapping, you must specify Q on every line at which Rigid Tapping is to occur.

Note: At the bottom of the hole, G84 will call the default version of the specified M function even if it has been

customized by an M function macro.

WARNING

FEED HOLD is temporarily disabled during the tapping cycle, but it will be re-

enabled at the end of the cycle.

NOTICE

Pressing CYCLE CANCEL while the tap is in the hole will very probably break the tap

or strip the threads in the tap hole. However, do so if it is an emergency.

Loading...

Loading...