M-Series Operator’s Manual 4/9/15

Parameters 20-30 (also 132-135, 236-239) - Motor Temperature Estimation

These parameters are used for motor temperature estimation. Parameters 20, 29 and 30 correspond respectively to the

ambient temperature of the shop, the overheating warning temperature, and the job cancellation temperature, all in

degrees Fahrenheit. Parameters 21-24 and 132-135 are the heating coefficients. Parameters 25-28 and 236-239 are the

cooling coefficients.

To disable Motor Temperature Estimation for an axis, set its heating and cooling coefficients to 0. For example, to

disable Motor Temperature Estimation for axis 1, set Parameter 21 to 0, and set Parameter 25 to 0.

Note: Temperature estimation only applies to controls operating in Torque mode (i.e. DC brushed systems and

Centroid AC systems). MPU11 systems running in Velocity mode (i.e. third party drive systems) do not use this

feature, and thus should be disabled (by setting all heating and cooling coefficients to 0).

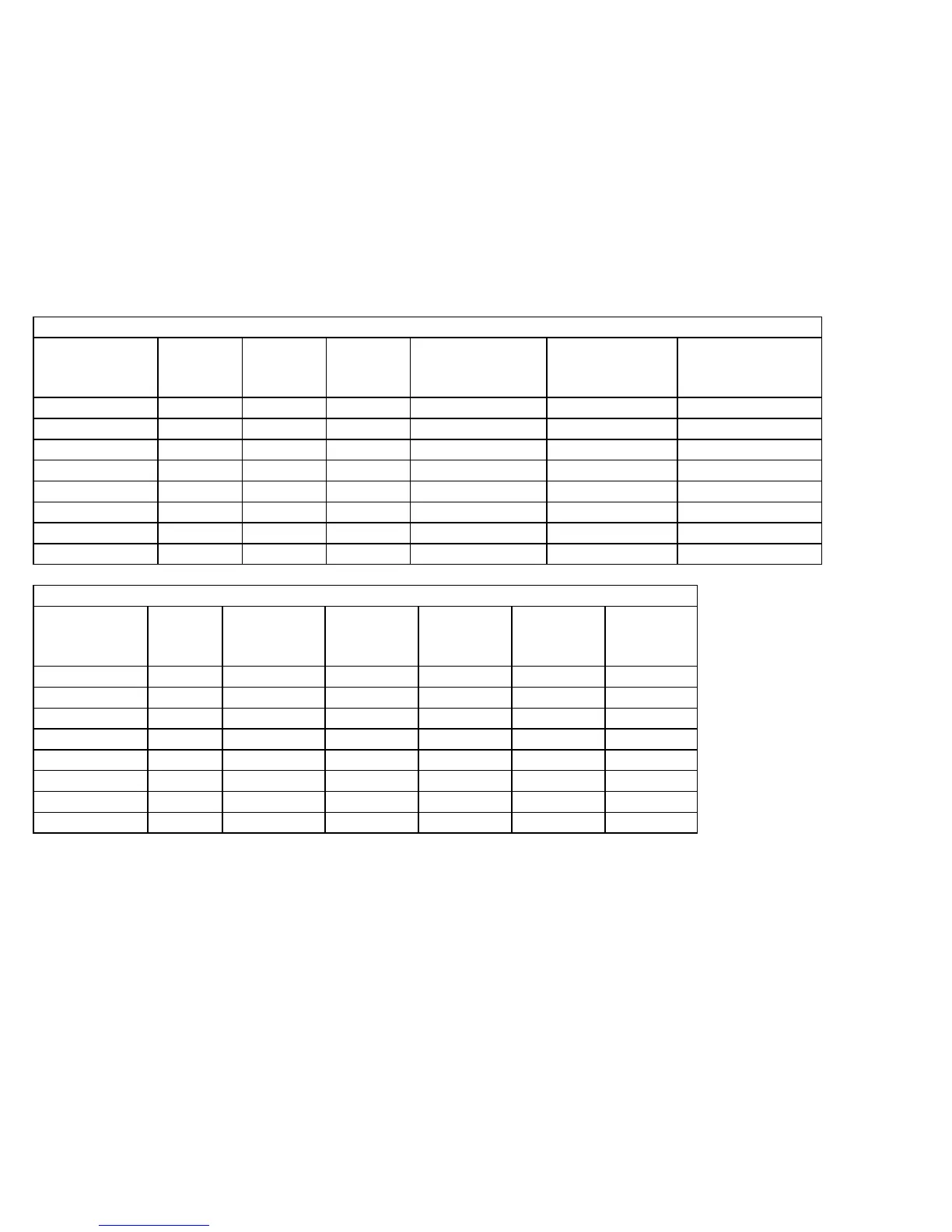

Suggested values for AC Brushless Motors and Drives

SD

Drive

SD3, SD1

750 W

motors

SD3, SD1

1,2 KW

motors

SD3, SD1

(finned heatsink)

1,2 KW motors

SD1 45A

(finned heatsink)

3 KW motors

SD1 45A

(finned heatsink)

4 KW motors

Parameters Axes Values Values Values Values Values

21-24 1-4 0.23 0.5 0.23 0.23 0.23

132-135 5-8 0.23 0.5 0.23 0.23 0.23

25-28 1-4 12.0 9.0 12.0 12.0 14.5

236-239 5-8 12.0 9.0 12.0 12.0 14.5

20 N/A 72 72 72 72 72

29 N/A 150 150 150 150 150

30 N/A 180 180 180 180 180

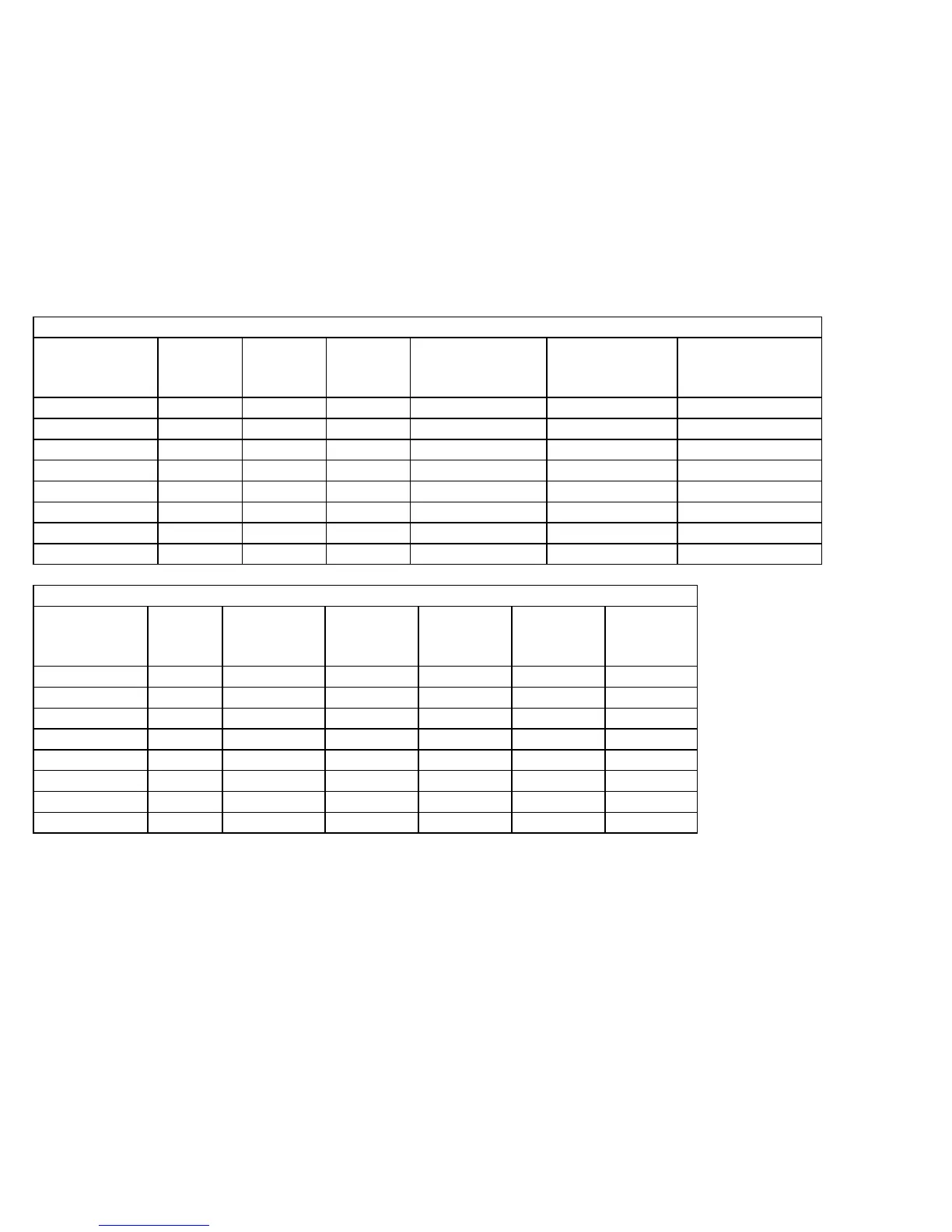

Suggested values for DC Brush Motors and Drives

Servo

Drive

9A Drive,

16 in/lb

motors

12A Drive,

29 in/lb

motors

15A Drive,

29 in/lb

motors

15A Drive,

40 in/lb

motors

25A Drive,

40 in/lb

motors

Parameters Axes Values Values Values Values Values

21-24 1-4 0.028 0.02 0.027 0.03 0.04

132-135 5-8 0.028 0.02 0.027 0.03 0.04

25-28 1-4 0.68 0.68 0.68 0.68 0.68

236-239 5-8 0.68 0.68 0.68 0.68 0.68

20 N/A 72 72 72 72 72

29 N/A 150 150 150 150 150

30 N/A 180 180 180 180 180

Parameter 31 - Legacy SPIN232 Com Port

For values 1-255, CNC11 will attempt to open that COM port and send out spindle commands. CNC11 should be

restarted after changing this value from 0 (disabled) to a valid value. Note that the baud rate is assumed to be 19200 to

work specifically with a SPIN232.

Parameter 33 - Spindle Motor Gear Ratio

NOTICE

The default value for this parameter is 1 and should not be changed unless you have

consulted your dealer or local Technical representative!!!

Parameter 33 is used for the gear or belt ratio between the spindle motor and the chuck in high gear range. It should be

greater than 1.0 if the motor turns faster than the chuck and less than 1.0 if the chuck turns faster than the motor. Note:

this value applies to high range. The ratio between high range and lower ranges is established by the gear ratio

parameters (65-67).

Loading...

Loading...