M-Series Operator’s Manual 4/9/15

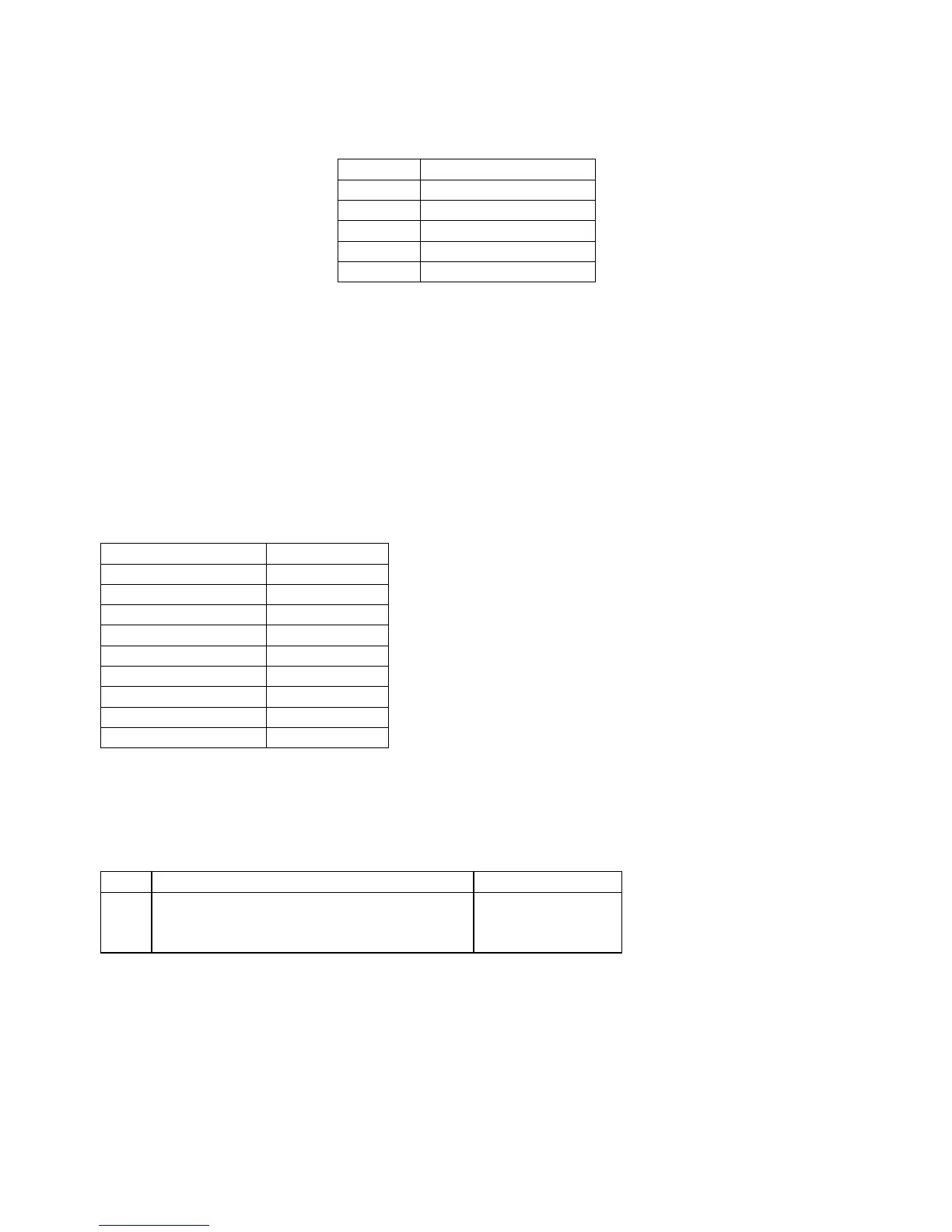

Parameter 17 – Detector Location Return Point

A non-zero value specifies the number of the reference return point (entered into the WCS menu) directly above a

permanently mounted TT-1 tool detector. When the Auto function is called up in the tool offset library, the control will

position the table to the return point specified by this parameter, and touch the tool off the TT-1 Tool detector.

Entry Return Point

0 None

1 G28

2 G30

3 G30P3

4 G30P4

A zero indicates that the tool detector is no permanently mounted; automatic tool measurement will be performed

without X/Y axis movement.

Parameter 18 - PLC Input Spindle Inhibit Parameter

This parameter stores the input for the Spindle Inhibit feature. A negative value must be entered if a "normally closed"

probe is to be used with the control. A positive value must be entered if a "normally open" probe is to be used with the

control. The absolute value of Parameter 18 will directly reflect the PLC input the Spindle Inhibit is wired to. When

this parameter is set, Digitizing and Probing cycles will not run unless a probe or touch-off block is connected. This

parameter is used to prevent the tool or probe from crashing into the table. The default for this parameter is 0, which

disables this feature.

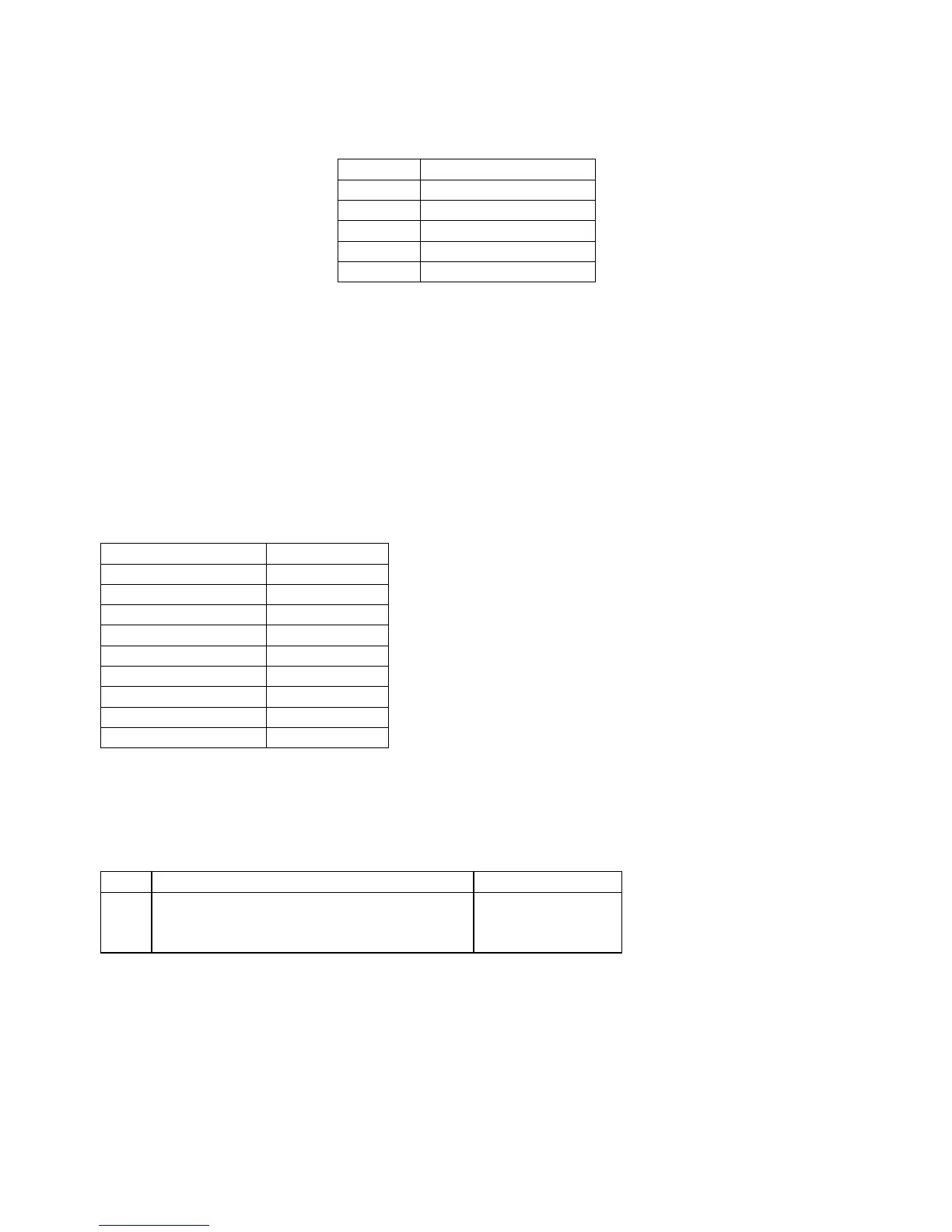

PLC Type/Model Input Number

Allin1DC 50771

MPU11 50771

DC3IO/DC3IOB 15

RTK3 15

Servo3IO/M15DRV1

5

PLCIO2 10

15/15 10

RTK2 10

Koyo ATC 2

Parameter 19 - MPG modes

The MPG is a hand-held device that is used as an alternate way of jogging the machine. This parameter defines the

MPG’s mode of operation.

Bit Function Description Parameter Value

2 Enable Z axis MPG* -- This will allow the z-

axis to be moved with the MPG while

running a job independent of the x and y axes

Yes = 4, No = 0

*PLC program interaction is needed for these features. The plc program is in direct control of MPG modes. Z-axis

MPG operation is not available with all controls.

Loading...

Loading...