M-Series Operator’s Manual 4/9/15

Parameter 39 - Feedrate Override Percentage Limit

This parameter is used for limiting the upper end of the Feedrate Override Knob percentage to a value from 100% to

200%. This parameter can be used to restrict the Feedrate Override Knob effect on machines with maximum rates

over 200 in/min. The Feedrate Override Knob percentage is normally allowed to go to 200%. However, on machines

with high cutting speeds, if the knob is turned up to 200%, it creates overshoots on corners. If this parameter is set to

something like 110, it will stop the Feedrate Override Knob from exceeding 110% and thus causes the overshoots to

disappear. The PLC program must check this parameter to actually enforce the limiting of Feedrate Override.

Parameter 40 - Basic Jog Increment

This parameter holds the basic jog increment for linear axes (0.0001" or 0.002 mm by default). This value works in

conjunction with the x1, x10, and x100 jog keys to determine the amount to move a linear axis during incremental

jogging.

Parameter 41 – Rotary Axis Jog Increment

This parameter holds the jog increment for rotary axes (0.01° by default). This value works in conjunction with the x1,

x10, and x100 jog keys to determine the amount to move a rotary axis during incremental jogging.

Parameter 42 – Password for Configuration Menus

This parameter determines the password that the user must enter in order to gain full access to the configuration

menus.

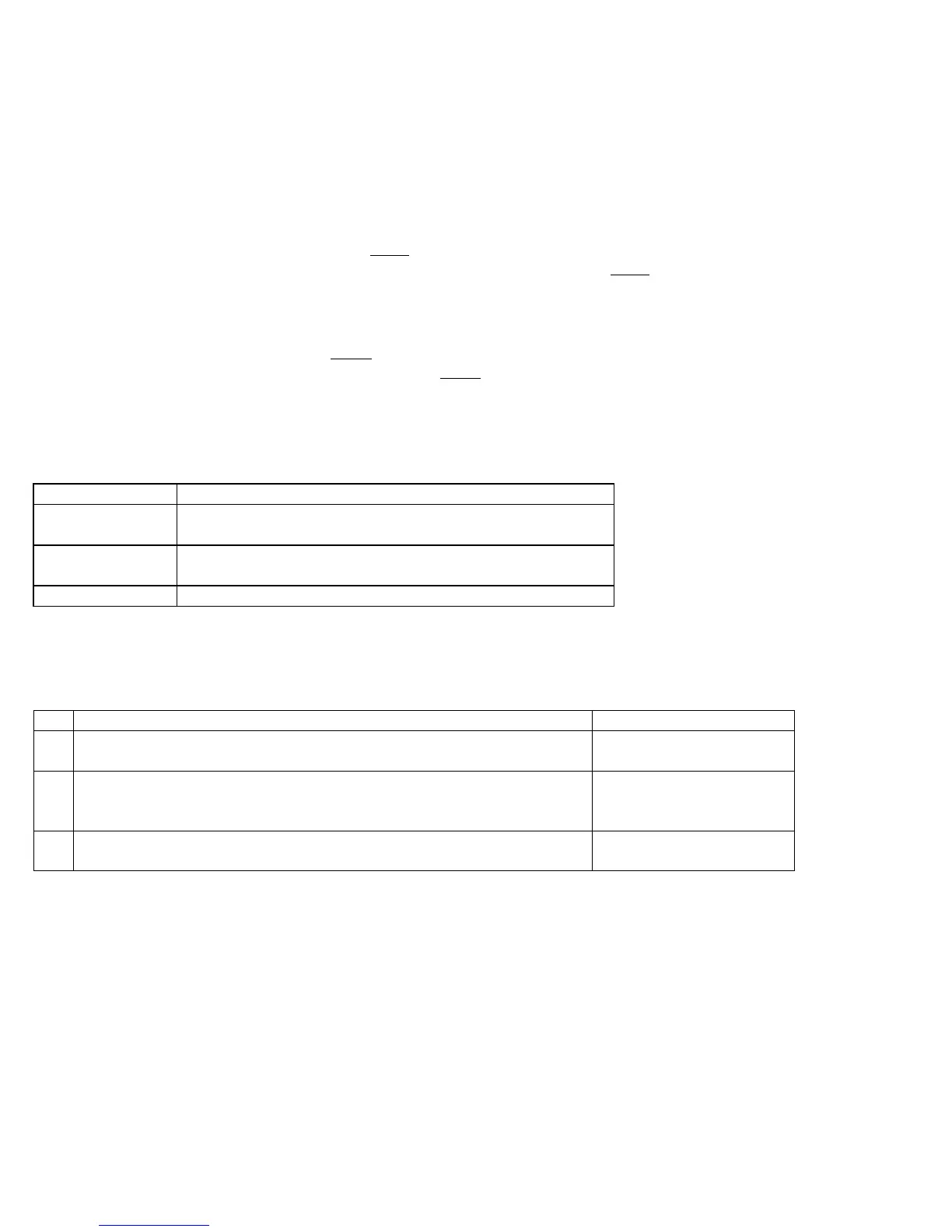

Value Meaning

54.0 No password required for supervisor access; the user is not

prompted for a password

ABCD.ABCD Password is 4 digits represented by “ABCD”

Example: for the password to be 1234, set to 1234.1234

Any other number Password is “137”

Parameter 43 – Automatic tool measurement options

This parameter is a bit field that is used to configure properties of the TT1.

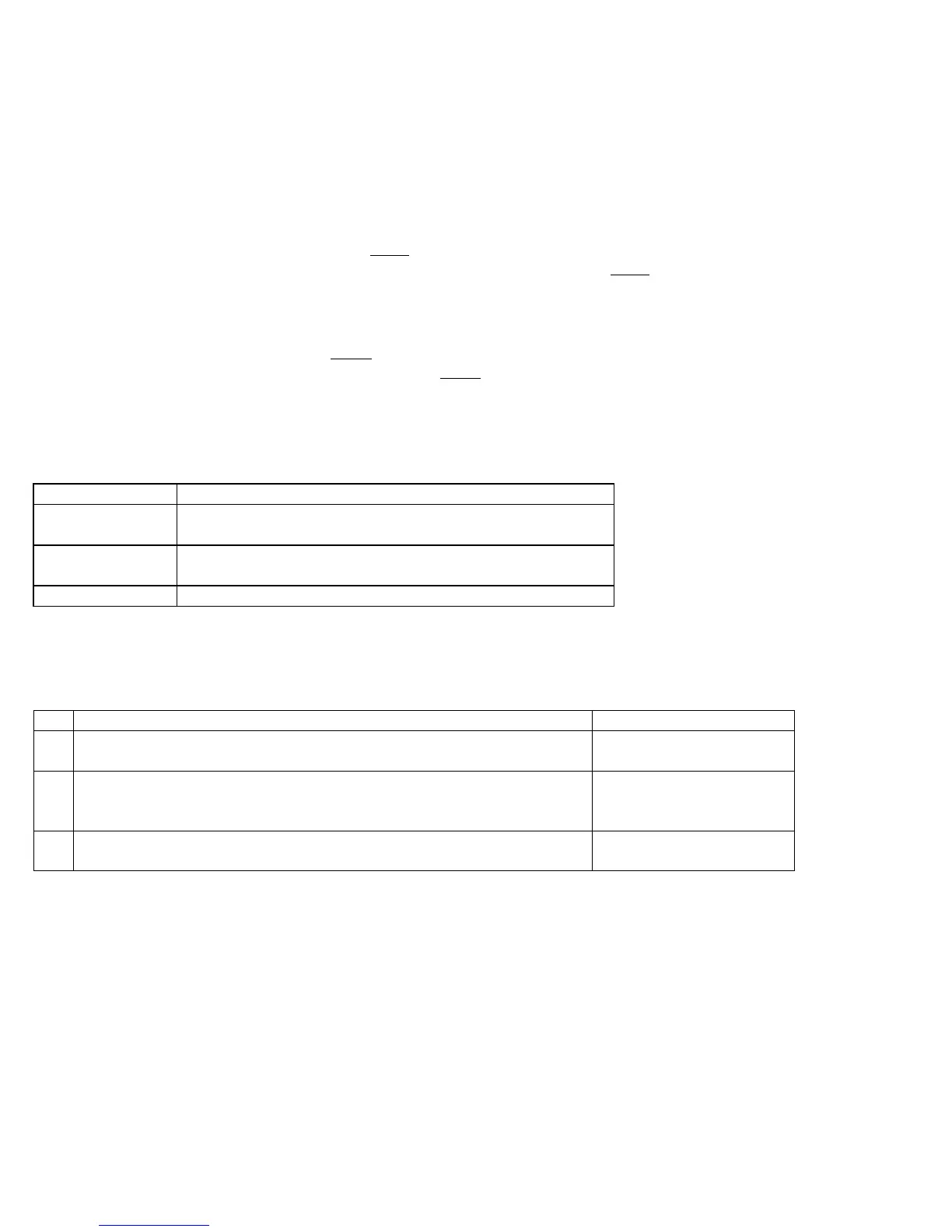

Bit Function Parameter Value

0 The height of the tool detector (parameter 71) will be subtracted from the

measured height of the tool.

Yes = 1; No = 0

1 Which PLC input to use for the Tool Z reference measurement.

0 = Use Touch Probe input in Parameter 11.

2 = Use TT1 input in Parameter 44.

0 = Use Parameter 11.

2 = Use Parameter 44.

2 Remind the operator to plug in the TT1 before doing Batch Tool

Measuring.

Yes = 4; No = 0

Parameter 44 – TT1 PLC input number

This parameter is the input number that the TT1 is wired into on the PLC. If a shared PLC input is used for the TT1

and the DP4 probe, then the value can be left at zero or set to the same value as parameter #11.

NOTICE

If you are using a different PLC input for the TT1 and DP4 when setting the Z reference

in the tool library with the DP4, make sure you don’t use a ruby probe tip. The TT1 is

electrical continuity based and the ruby tip is not electrically conductive!

Loading...

Loading...