M-Series Operator’s Manual 4/9/15

Parameter 146 – Feed Hold Threshold for Feed Rate Override

This parameter sets the lowest value permitted as the feed rate override percentage before feed hold is engaged. Feed

hold will be released when the override percentage is greater than this value.

Parameter 147 – Number of Status Messages to keep in Operator Message Window

The Operator Message Window is the box of scrolling status messages that appears in the upper right corner of the

Main Screen. The number of remembered status messages can be adjusted by this parameter.

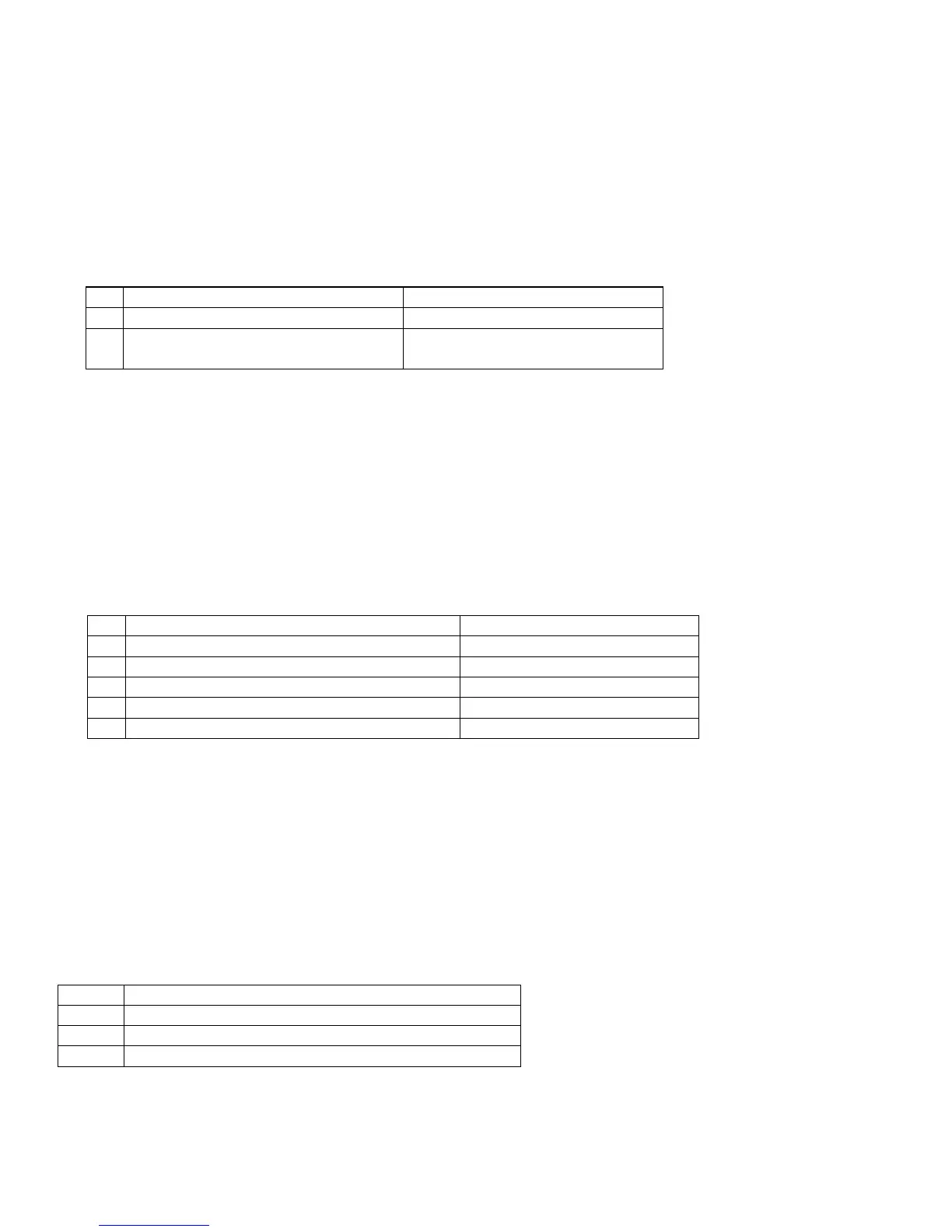

Parameter 148 – Miscellaneous Jogging Options

This parameter enables and/or disables certain optional modes of jogging.

Bit

Function Description Parameter Value

0 Unused Should be set to 0

1 Prohibit Keyboard Jogging Prohibit Keyboard Jogging = 2

Keyboard Jogging allowed = 0

Note: With this parameter set to zero, you need to set parameter 170 to enable keyboard jogging.

Parameter 149 – Spindle Speed Threshold

This parameter defines the spindle speed threshold percent for the “Slave feedrate to spindle speed” function and the

“Spindle up-to-speed” function, both of which are enabled and disabled via Parameter 78. It is specified as a

percentage of the programmed spindle speed. For example a value of 0.8 means 80 percent of the programmed

spindle speed. See Parameter 78 for more details.

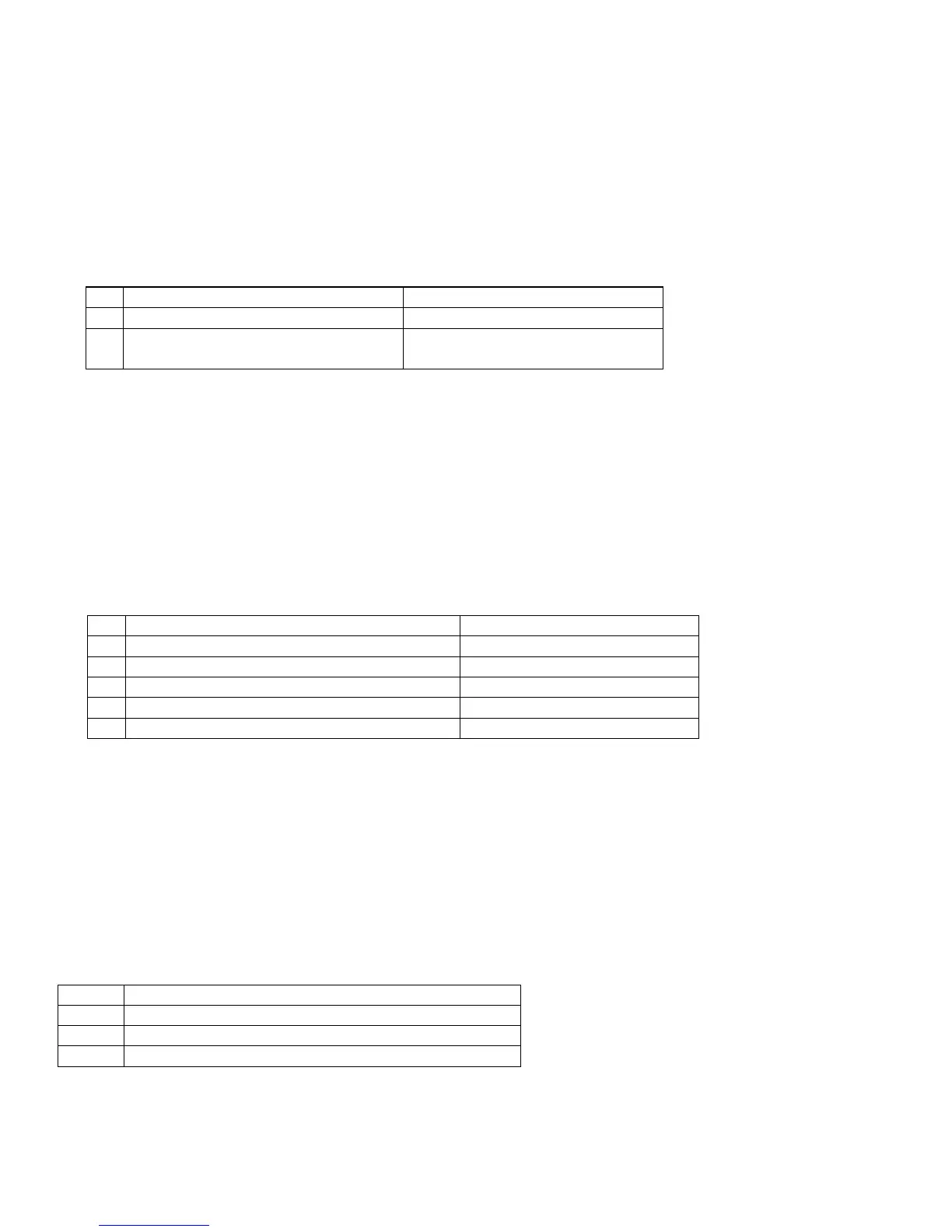

Parameter 150 – Backplot Graphics display options

This parameter controls the various options related to backplot graphics.

Bit

Function Description Parameter Value

0 Sets Run Time Graphics option default to ON Enable = 1, Disable = 0

1 Displays CSR positions in graphing Enable = 2, Disable = 0

2 Display A and B rotations for 5 axis machines Disable = 4, Enable = 0

3 Display Skew Correction Enable = 8, Disable = 0

4 Display Lash/Screw Compensation Enable = 16, Disable = 0

Parameter 151 – Repeatability tolerance for probing and radial digitizing.

Default is 0, repeatability check disabled. When disabled, only one measurement per point is taken in the probing

cycles and radial digitizing. When enabled, a minimum of two measurements are taken per point and the difference (if

any) is then compared to the repeatability tolerance as set in Parameter 151. If the difference is less than or equal to

parameter 151 the point is stored and probing continues. If the difference is greater than parameter 151, 2 more

measurements are taken and the process repeated up to a maximum of 10 times. In probing cycles, if the repeatability

tolerance cannot be met the cycle is cancelled and an error message generated. In radial digitizing, the point is

discarded and digitizing continues without interruption.

Parameter 155 – Probe Type

This parameter specifies the type of probe being used.

Value Meaning

0 Standard Mechanical probe

1 DSP probe

2 DP-7 probe

Parameters 156-159 – Autotune Move Distance / Auto Delay Calculation Move Distance for axes 5-8

See parameters 95 – 98 for more information.

Loading...

Loading...