M-Series Operator’s Manual 4/9/15

Parameter 323 – MPU11 Encoder Speed Filter

This is an axis bitfield where setting a bit to ‘on’ selects the low speed filters for the corresponding axis. As a general

guideline, an axis’s bit should be set unless that axis refers to a 3rd party drive. Bit 0 (value 1) refers to axis #1, bit 1

(value 2) refers to axis #2, bit 2 (value 4) refers to axis #3, bit 3 (value 8) refers to axis #4, and so forth.

Parameter 324-331 – Axis Boxcar Size

These parameters set the maximum sample size of the boxcar filter for each axis. For most applications these values

should be set to 0 (default). For applications where the motor drives are too responsive or jumpy, these boxcar filters

act as a way to smooth the PID output. They average the PID output by the entered boxcar size thus reducing PID

spikes. Eg. A value of 4 would add the last 4 PID values and then divide by 4 for before output. A value of 5 would

add the last 5 PID values then divide by 5 before output. Note that during PID averaging, the Error Sum is not zeroed

during direction reversal. Conversely, a value of 0 disables the boxcar filter for that axis and also zeroes the Error Sum

on Direction Reversal. Note also that as a byproduct of averaging by 1, a boxcar value of 1 may be used to produce a

true PID output while not zeroing the Error Sum on direction reversal.

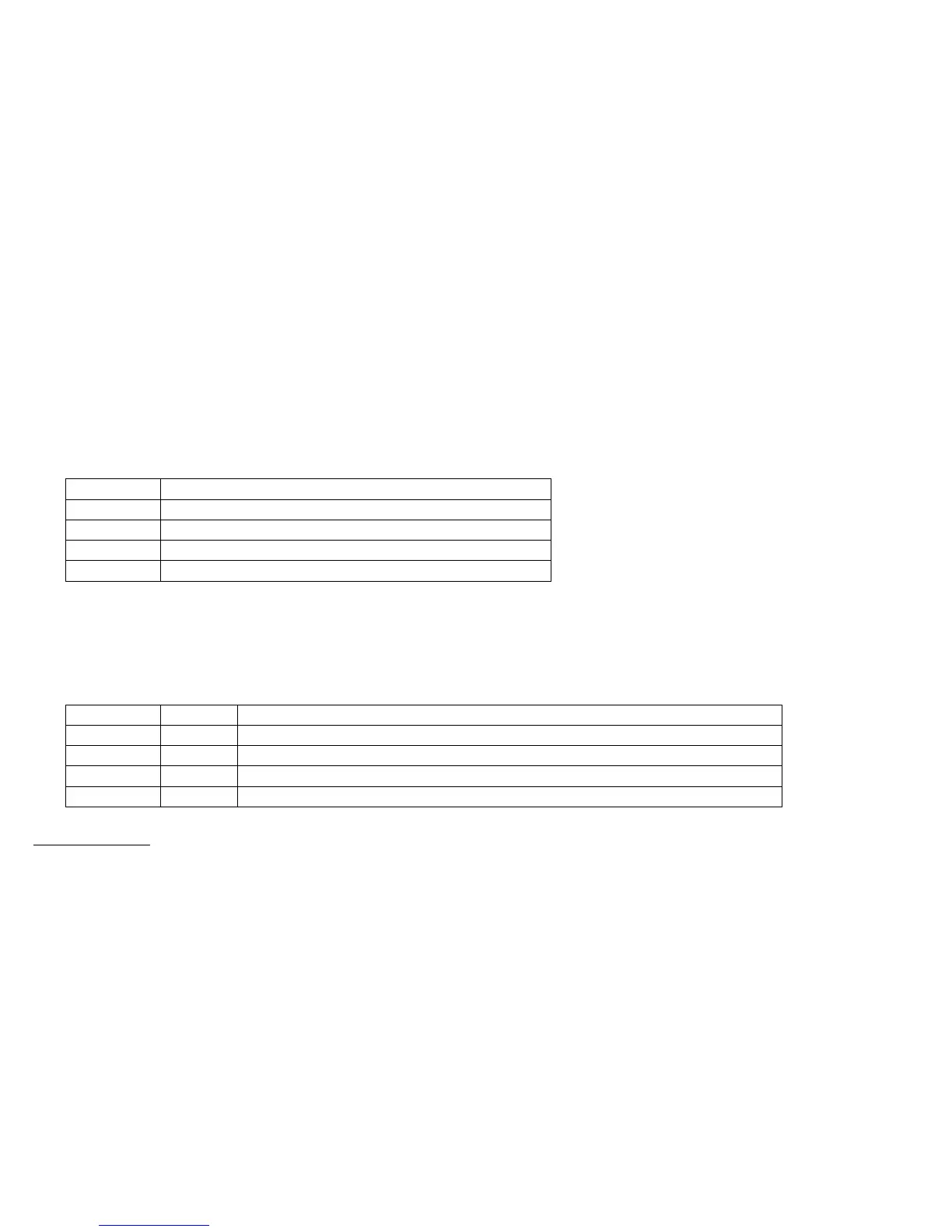

Parameters 332-335 – Encoder error suppression

These parameters control suppression of various types of encoder errors on a per encoder basis. These parameters are

bitfields by encoder index, NOT axis index. The mpu11 has 15 encoder indexes. For example to disable encoder faults

for Encoder #5 on the mpu11, enter a 16 into the parameters 332 and 334. To suppress encoder faults and error

messages for all 8 axes, enter 255 into each of the paramters mentioned in the following table.

Parameter

Function

332 Suppress encoder differential faults

333 Suppress encoder differential error messages

334 Suppress encoder quadrature faults

335 Suppress encoder quadrature error messages

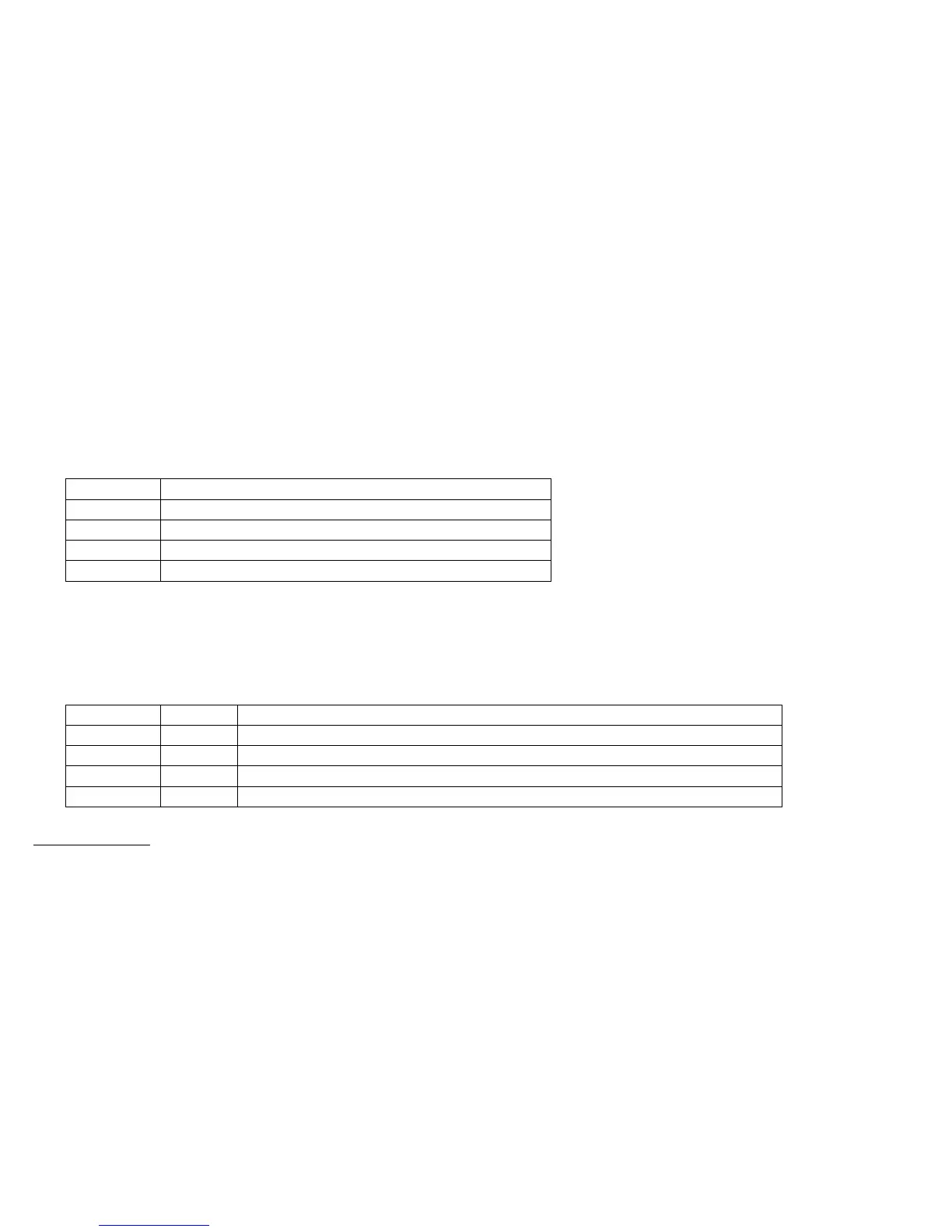

Parameters 336-339 – Motor torque estimation for velocity mode drives

These parameters are intended to be used with velocity mode drives in order to faciliatate a more accurate display of

the axis load meter bars shown under each position in the main DRO display. If P336 = 0, then this feature is disabled

and the normal PID output is displayed by the axis load meter bars. This feature is enabled if P336 is non-zero.

Parameter

Symbol Function

336 G Overall gain setting (0 = disable Motor torque estimation)

337 Ga Absolute error gain

338 Gs Error sum gain

339 Gd Delta error gain

Technical details:

The axis meter bar value (V) is then caluculated as: V = abs(100.0 * G * ((Ea*Ga + Es*Gs + Ed*Gd)) /

integration_limit), where Ea is the absolute error, Es is the error sum, and Ed is the delata error from the PID algorithm

and the integration_limit is from the “Limit” value set in the PID Config screen . This value V is then bound to the

range 0-100.

Parameters 340-347 – Precision Mode delay (in milliseconds) for axes 1-8

These parameters are used for synchronizing individual precision mode drives with different delays. The MPU11 will

use these values and compensate for the differences in the delays. These parameters have up to a 0.25 millisecond

resolution.

Parameter 348, 351, and 354 – MPG/Handwheel Encoder Input 1, 2, and 3

The encoder input for the MPG or handwheel. (1-15) See the encoder chart above. Note: PLC program interaction is

needed to enable an MPG or handwheel.

Loading...

Loading...