M-Series Operator’s Manual 4/9/15

Parameter 349, 352, and 355 – MPG/Handwheel Detents per Revolution 1, 2, and 3

This value is the number of clicks (detents) per revolution. It is the number of divisions or markings on the mpg or

handwheel. Moving the mpg or handwheel one detent or division will cause the motor to move one jog increment

(depending on the multiplier x1, x10, x100, etc). . Note: PLC program interaction is needed to enable an MPG or

handwheel.

Parameter 350, 353, and 356 –MPG/Handwheel Encoder Counts per Revolution 1, 2, and 3

This value is the number of counts generated per rotation of the mpg or handwheel. Note: PLC program interaction is

needed to enable an MPG or handwheel.

Parameters 357-364 – Axis Drive Max RPM for Axes 1-8

These parameters allow you to set the drive/motor max rate capability (in RPMs) for use by the PID algorithm for the

calculation of the axis KV1 contribution. This value is independent from the axis Max Rate setting in the Jog

Parameters menu, which is used by the control software. However, for those axes whose corresponding parameters are

set to 0 (the default) the the PID algorithm will use the axis Max Rate setting in the Jog Parameters for the calculation

of the axis KV1 contribution. These parameters are intended for 3

rd

party velocity mode drives that have a different

max rate setting than that of the control software.

Parameters 365 – Drive power-on delay

This specifies the number of milliseconds that the MPU11 will wait between the moment that drive power first comes

on and the start of commanded motion. However, this does not work for the case of turning off a single axis using

M93, moving a different axis, and then moving the powered off axis. The default value is 0 which means no delay.

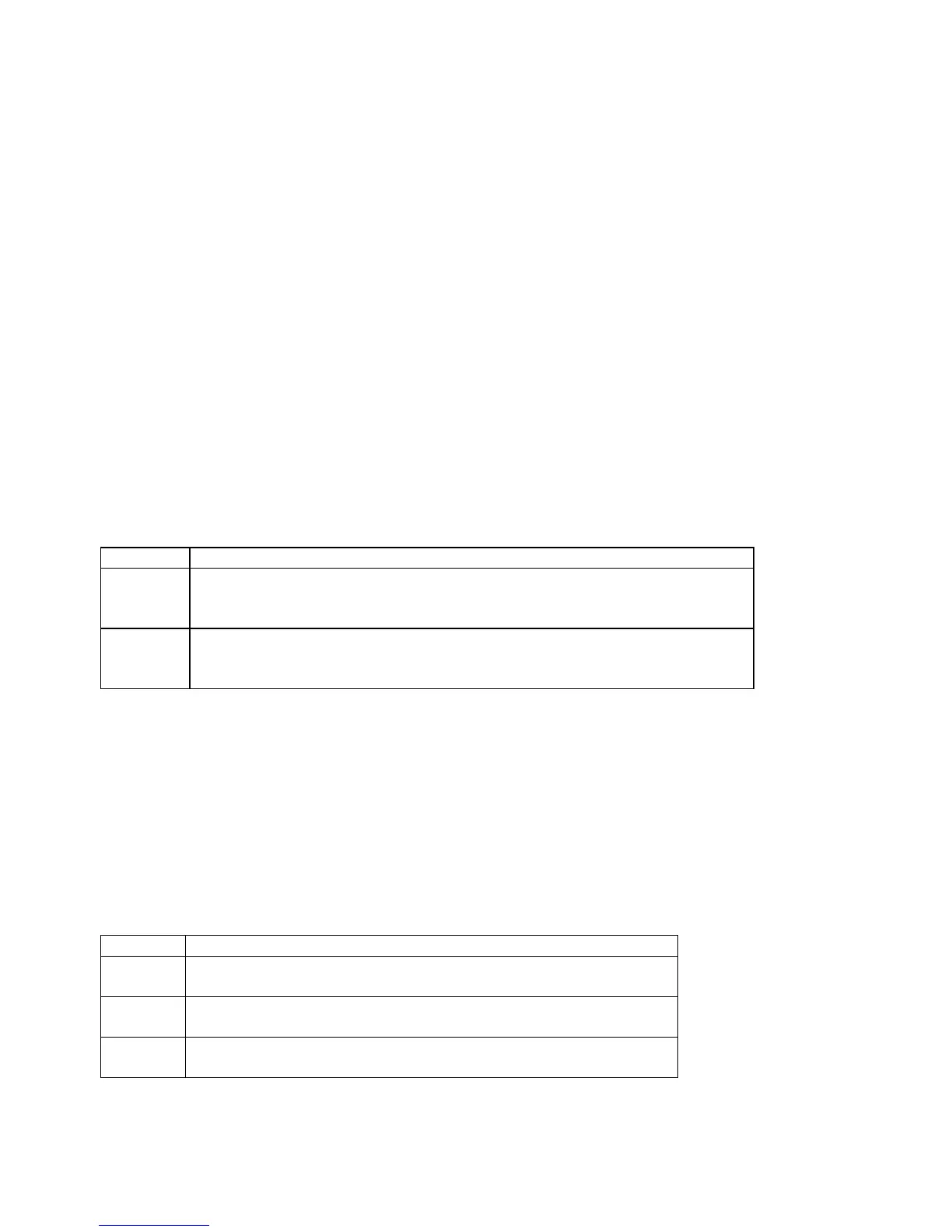

Parameters 366 / 367 – Probe / TT1 deceleration multiplier

Parameter

Function

366 Probe deceleration multiplier:

This factor adjusts the deceleration rate of probing moves coming to a stop due

to probe hit.

367 TT1 deceleration multiplier:

This factor adjusts the deceleration rate of TT1 tool measuring moves coming to

a stop due to tool touch detect.

The normal axis acceleration rate (configured by dividing the Max Rate in the Jog Parameters screen by the Accel

Time in the PID Config screen) is multiplied by the value of these parameters to determine the actual decelerations

used for each situation. A value higher than 1 will cause a more abrupt deceleration than the normal axis

configuration. A value below 1 will cause a gentler deceleration.

Parameters 374-379 – ACDC Drive Debug Log Settings

These parameters are used by support technicians and should be left at value 0.

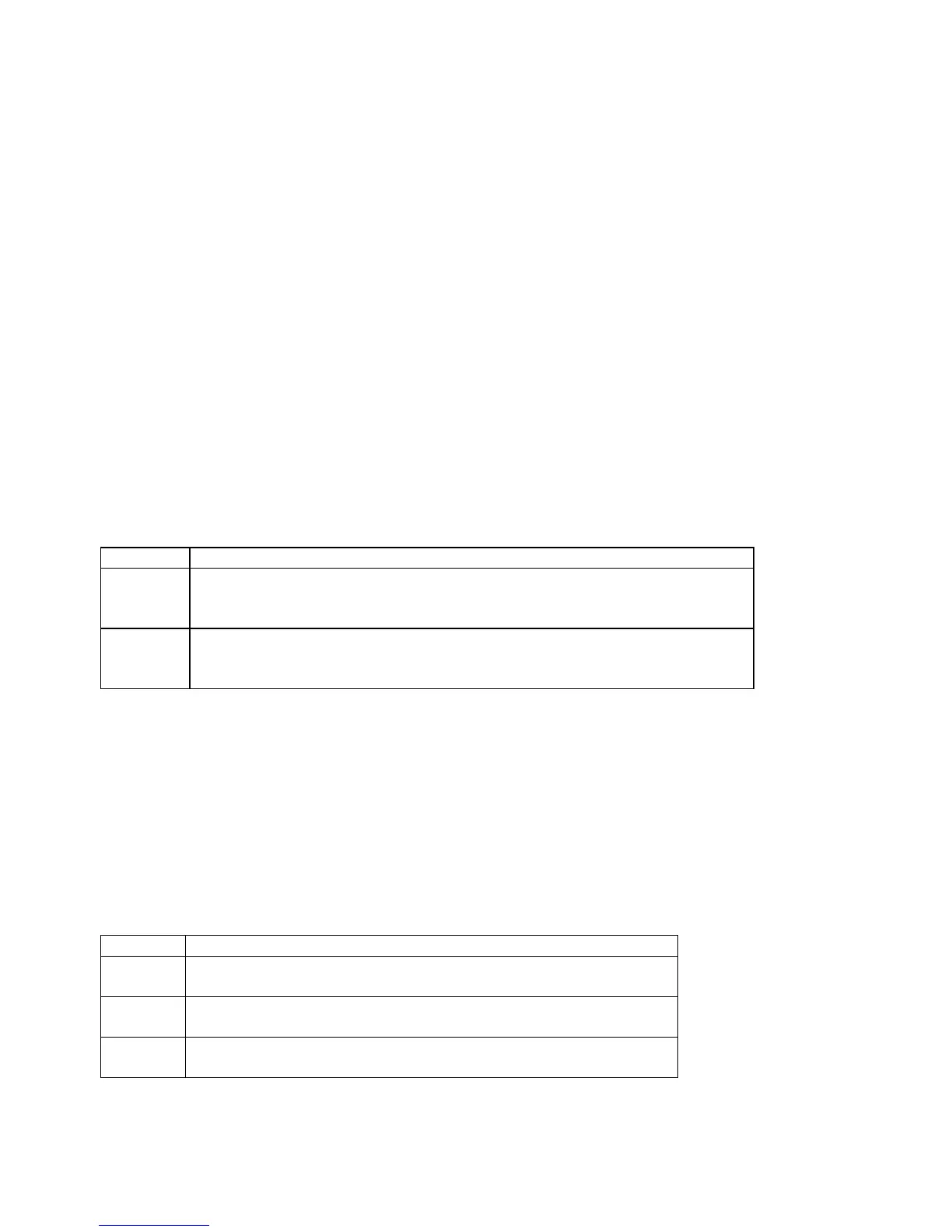

Parameters 392-394 – DP-7 parameters

These are parameters specific to the DP-7 probe and are used only if parameter 155 = 2.

Parameter

Function

392 DP-7 Pullback Distance:

The distance the probe moves off of the surface after a probing move.

393 DP-7 Pullback Feedrate:

The feedrate for the pullback move.

394 DP-7 Measuring Feedrate:

The feedrate for the slow measuring move.

Parameters 395 – Probing Setup Traverse Speed

This sets the probing traverse feedrate for the macro-based probing cycles on engine block systems.

Loading...

Loading...