M-Series Operator’s Manual 4/9/15

Parameters 396 – Probing Setup Plunge Speed

This sets the probing plunge feedrate for the macro-based probing cycles on engine block systems.

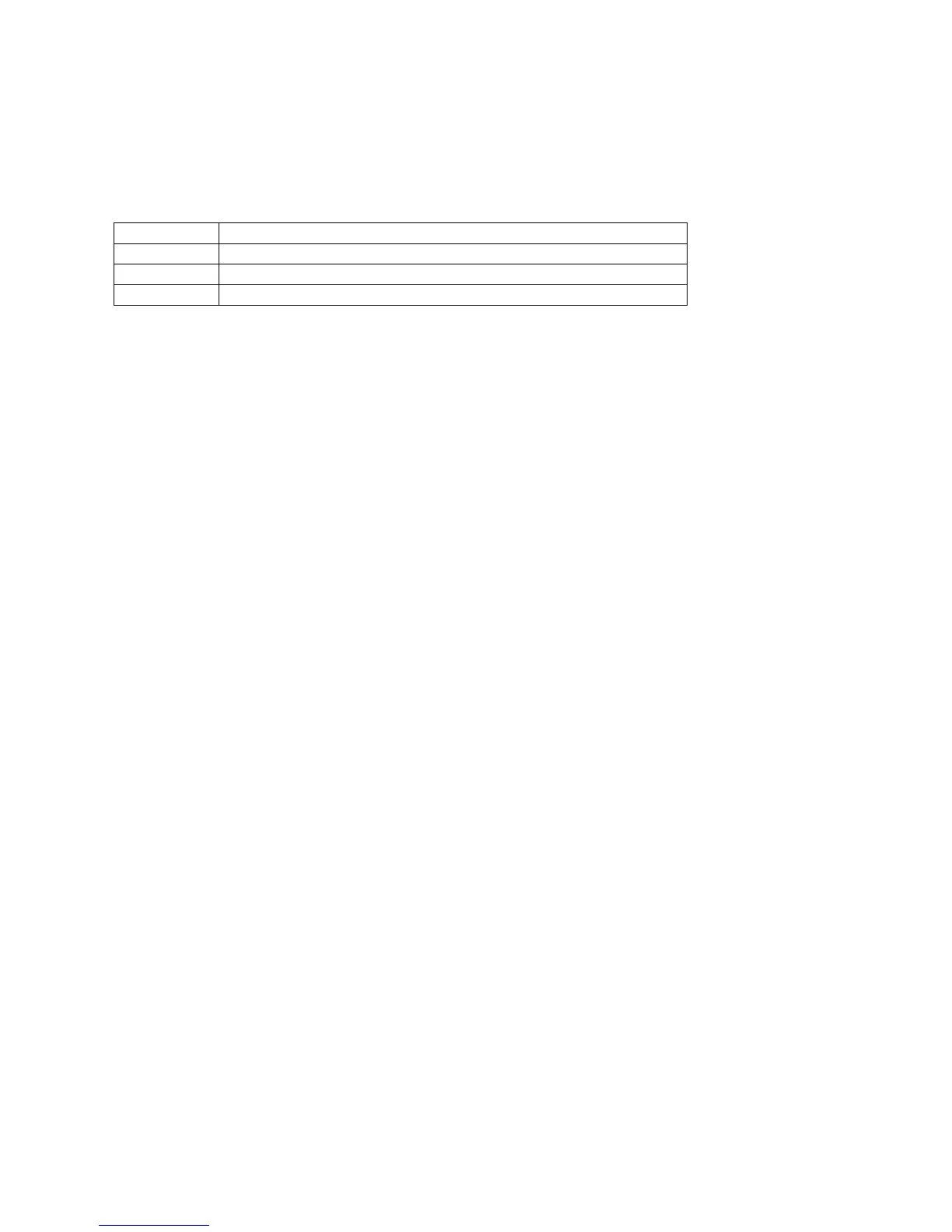

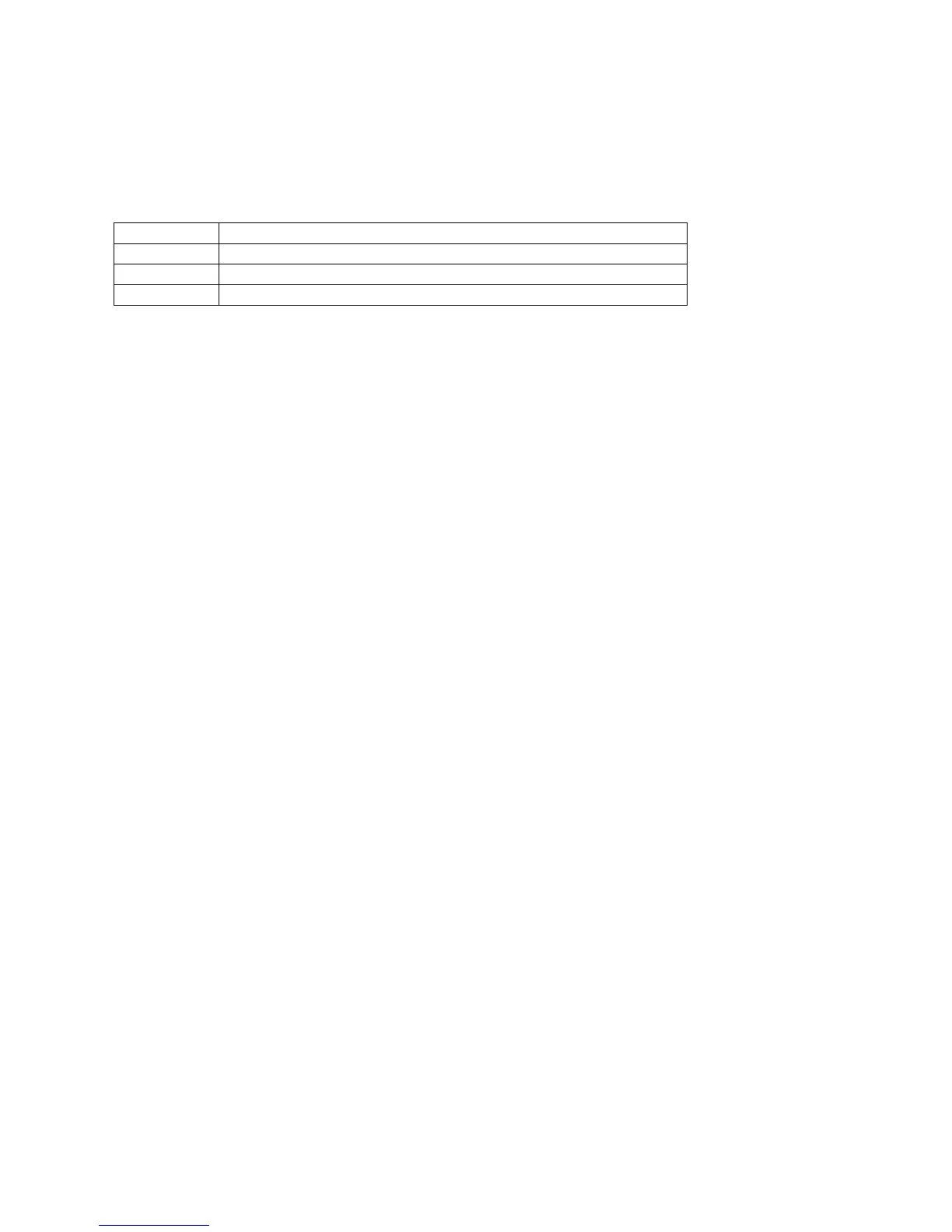

Parameters 398 – Port/Block mode

This determines the current mode of Port/Block systems and is set by the Port/Block menu. This parameter should not

be manually modified.

Value Mode

0 3-Axis

1 Engine Block

2 Tilt Table

.

Parameters 399 – AD1 arc chord tolerance adjustment

This parameter adjusts the precision of AD1 arcs. When Smoothing is turned off (P220 = 0) arc moves (such as G2 and

G3) are generated as a string of many small linear moves that are used to closely approximate the programmed arc.

These small linear moves are called arc chords. These arc chords straddle each side of the theoretical true arc path, but

their distance (in encoder counts) from the path is limited by what value is set in this parameter. The default value is

.5, meaning that by default the arc chord never strays away from theoretical true arc by more than ½ encoder count.

Parameters 900-999 – PLC program parameters

These parameters are used as a way of communicating floating point values to a PLC program. The meanings of these

parameters depends on how a PLC program uses them and can vary from one machine to another. One suggested use

of these parameters is as a set of configuration values. The values of these parameters are saved upon modification

(via a menu or CNC job) and will be retain their values even after shutdown and restart of the control software.

All remaining parameters are reserved for further expansion.

Loading...

Loading...