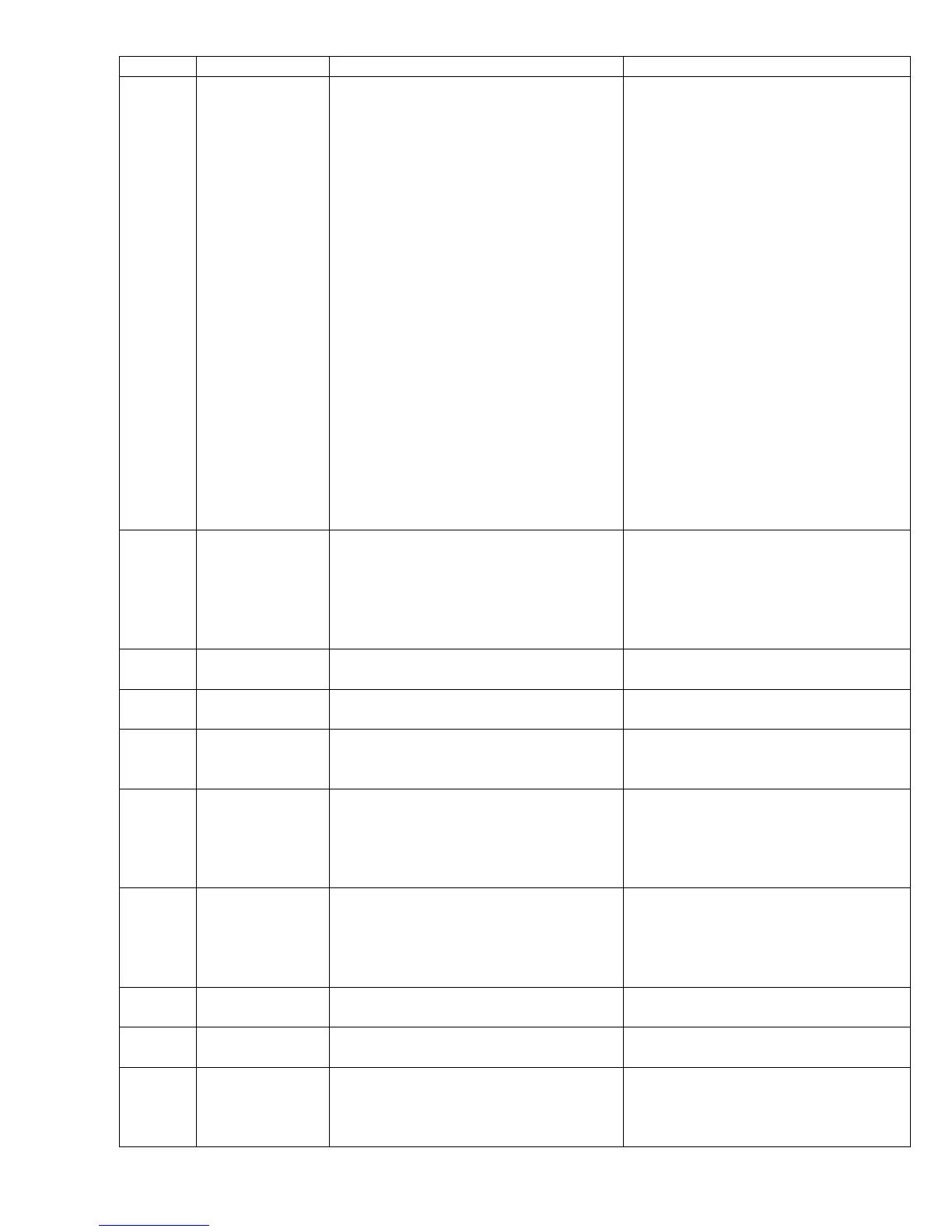

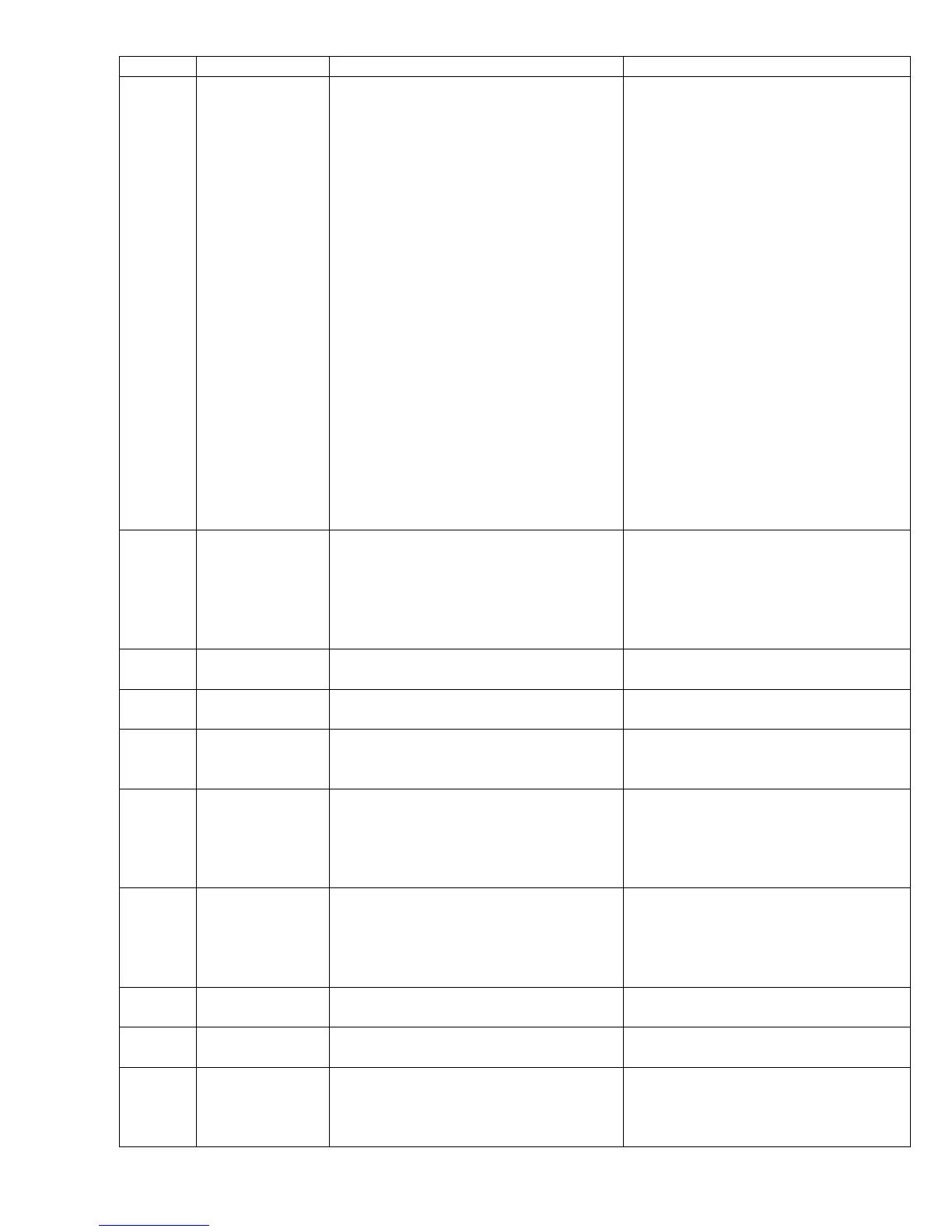

M-Series Operator’s Manual 4/9/15 15-5

Number

Message Cause & Effect Action

411 _ axis full power

without motion

90% Power (PID Output > 115) is

applied to any axis and no motion

>0.0005 inches is detected, for more

than the time specified in parameter 61

(default .5 sec.). All axis motion is

stopped and the CNC program is

aborted.

The probable causes of this error are:

1. One of the axes is against a physical

stop.

2. The servo drive has shutdown due to

a limit switch input.

3. The Z home switch is the same as the

Z + limit switch.

1. If the axis has run into a physical

stop, use the slow jog mode to move

the axis away from the stop. Determine

and set software travel limits to stop

machine before in runs into the hard

stops.

2. If the axis is not on a physical stop,

check for a tripped limit switch. If it is

then the software is commanding a

move into the switch but the hardware

is shutting the move down. Go to the

motor setup screen and enter the limit

switch input number if applicable.

3. Make sure the switch input is not

unstable or noisy. If it is then replace

the switch. If the problem persists it

may be necessary to create separate

home and limit switch inputs.

Use slow jog to move opposite the

direction causing the error and clear all

limit switches. Jog toward the direction

causing the error, if no motion occurs

then a servo drive failure is indicated.

412 _ axis encoder

differential error

An error condition was detected in the

differential signal levels for this axis

encoder. May indicate a loose or

severed encoder cable or a bad encoder.

This will stop all motion and cancel the

job.

Reconnect/replace encoder or encoder

cable.

417 Abnormal end

of job

Job ended without reason.

418 Search Line or

Block not found

Requested search input data not found

in loaded CNC file.

Type in correct data or load correct

job.

419 Search line in

embedded

subprogram

Requested search line is found, but is

part of an embedded/extracted

subprogram

Use another line number

420 _ axis motor

overheating

CNC software estimates that a motor

has reached the warning temperature

(set in Parameter 29). Motor is

overheating or the temperature file is

corrupted. Job will be cancelled.

Contact dealer.

Determine what’s causing motor to

overheat or delete cnc.tem file and

reboot.

421 Motor(s) too

hot: job

canceled

CNC software estimates that one or

more motors have reached the limit

temperature (set in Parameter 30). Will

not be able to run until motor cools

down.

Contact dealer.

Determine what’s causing motor to

overheat or delete cnc.tem file and

reboot.

422 Check Jog Panel

cable

Jog panel failure or loose cable. Reconnect jog panel cable.

428 Check MPG

cable

MPG failure, loose cable, or was turned

off.

Reconnect MPG cable and turn axis

selector knob to an axis.

434 _ idling too

high: Releasing

power

Axis is not moving and no job is

running but axis has stopped against

some abnormal resistance. Power is

released to motors.

Run an autotune to adjust motor

settings.

Loading...

Loading...