M-Series Operator’s Manual 4/9/15 15-6

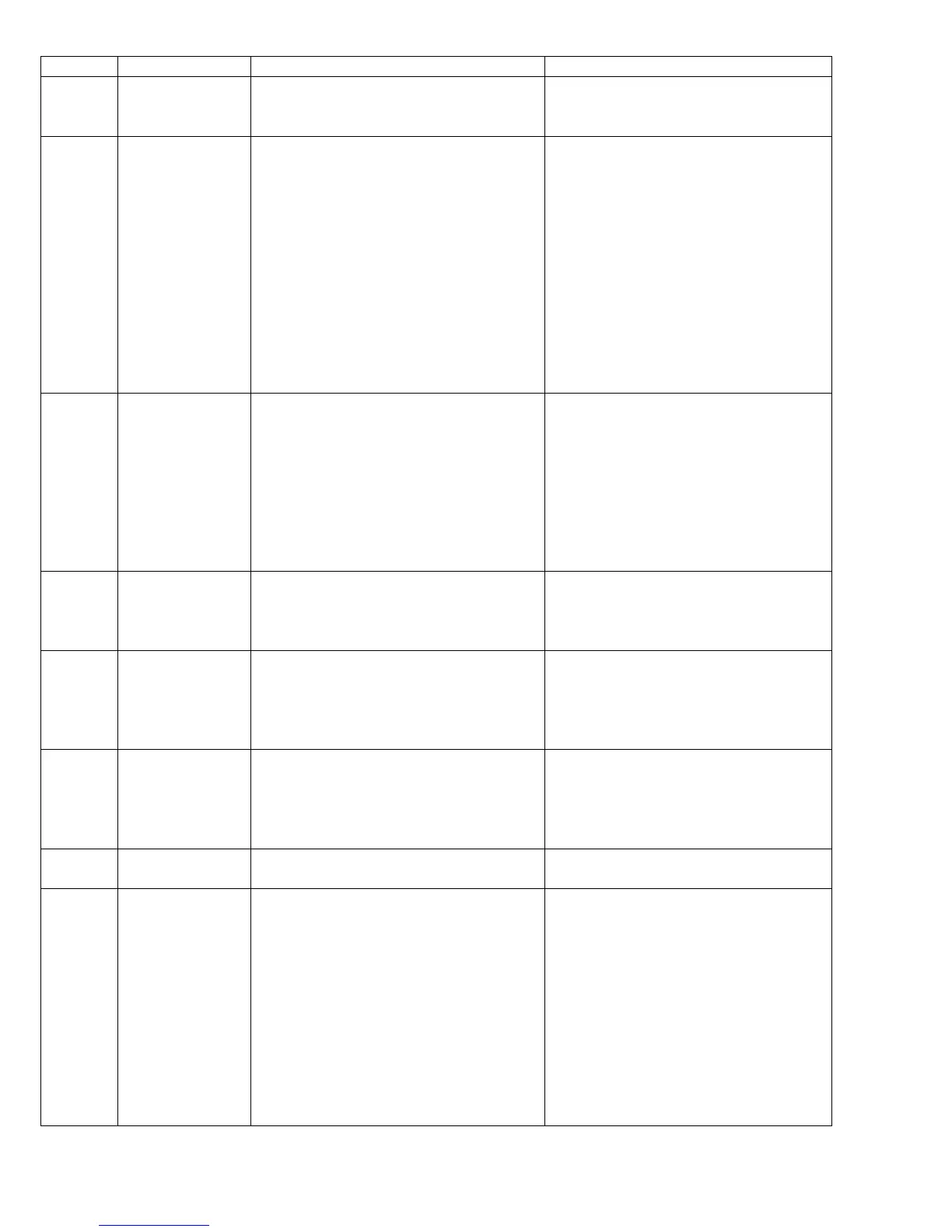

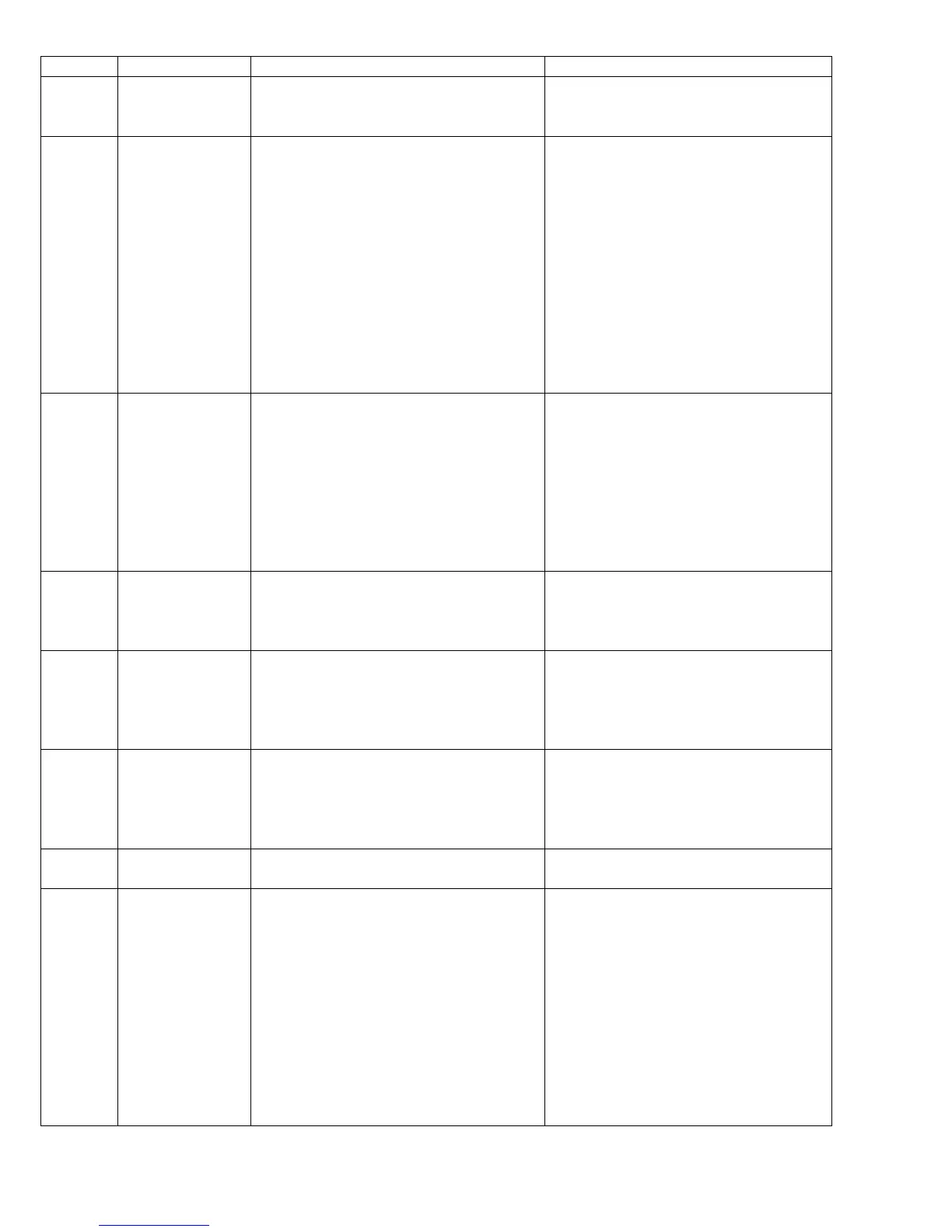

Number

Message Cause & Effect Action

435 _ axis runaway:

Check motor

wiring

Motor was in a runaway fault condition.

Power to motor will automatically be

shut off.

Check motor wiring

436 Servo drive

shutdown

This error message is produced by

hardware detection of a physical error.

The servo drive hardware generates this

error message if it detects either an

overcurrent or overvoltage condition.

The particular hardware condition is

reflected on the servo drive LED’s.

Once the servo drive detects this error

condition it stops all motion and

removes power to the motors. The

hardware indicates the presence of this

condition to the CNC software via the

servo drive fault input to the PLC.

On DC systems check status of the

servo drive LED’s and check fibers

4&5. If this message is displayed on an

AC system check P178 bit 4 is set.

437 Servo power

removed

Axis was moving more than 300 RPM

while power was supposed to be off.

1.) Motor may be wired backwards.

2.) May be a shorted servo drive.

3.) Axis motion is canceled but motor

continues to move due to inertia, which

is probably caused by an unbalanced

axis.

Power to motors is released.

Check motor wiring, servo drive, or

look at Kg value in PID and make sure

it’s not above +/- 5.

438 Spindle slave

position error

The slaved axis moved too far in the

wrong direction during a spindle-slaved

move (such as in rigid tapping). Job is

cancelled.

Check parameter 34 for wrong sign in

front of encoder counts.

439 _ axis servo

drive data output

error

Logic power failure or loss of

communication from the drive to the

MPU11.

Is logic LED on? Check fiber optic

cables to drive. For SD1 drives, make

sure bus cables are shielded and are as

short as possible. Power unit down

and check drive connections.

441 _ axis

overvoltage

Input power has gone higher than

340VDC and will shutdown the drive

and removes power. The motor brake

will engage for 5 seconds in this

condition.

Check input voltage is below 340VDC.

If not, incoming VAC needs lowered.

442 _ axis

undervoltage

Drive input power is less than 80 VDC. Check supply voltage.

443 _ axis

commutation

encoder bad

Control detected invalid commutation

zone value.

Perform a motor Move Sync in the

Drive menu. A Zero (0) or Seven (7)

is an invalid zone. Check for:

a.) Wiring problem in the encoder

cable or motor end cap (broken

encoder wires).

b.) Encoder cable shield connected at

motor end, when it shouldn’t be.

c.) Bad encoder.

d.) Motor power cable shields not

connected.

e.) Drive not grounded properly.

Loading...

Loading...