Revision 2016/03, 6ELE, V1.14

4-37

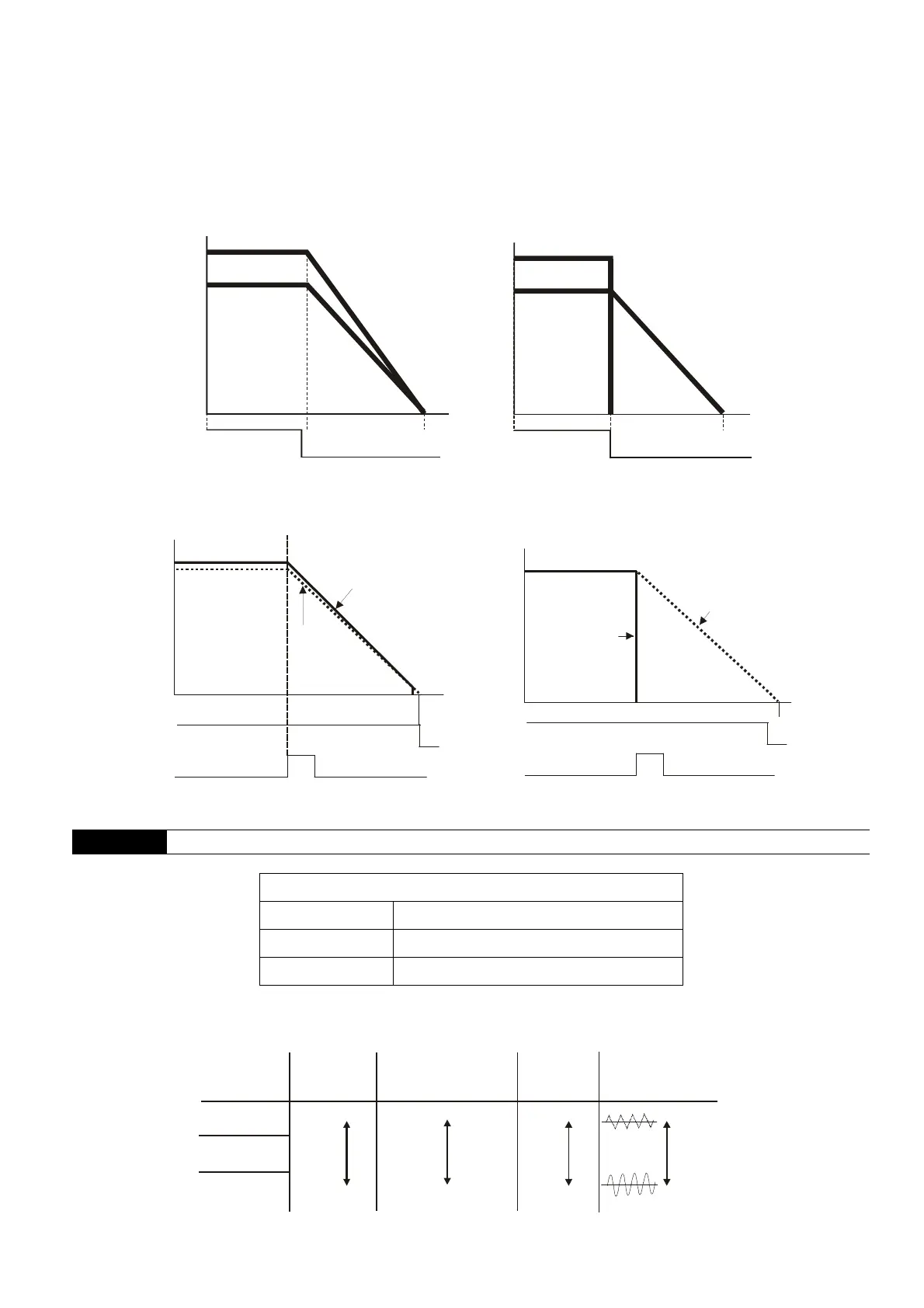

The motor stop method is usually determined by the characteristics of the motor load and how frequently it is

stopped.

(1) It is recommended to use “ramp to stop” for safety of personnel or to prevent material from being wasted in

applications where the motor has to stop after the drive is stopped. The deceleration time has to be set

accordingly.

(2) If motor free running is allowed or the load inertia is large, it is recommended to select “coast to stop”. For

example: blowers, punching machines, centrifuges and pumps.

RUN

STOP

Frequency

Time

Time

output

frequency

output

frequency

motor

speed

motor

speed

operation

command

operation

command

stops according to

decel eration time

free run to stop

ramp to stop and free run to stop

EF

frequency output

motor

speed

EF

operation

command

stops according to

decel eration time

When Pr.02.02 is set to 2 or 3

frequency

output

free run to stop

operation

command

When Pr.02.02 is set to 0 or 1

motor

speed

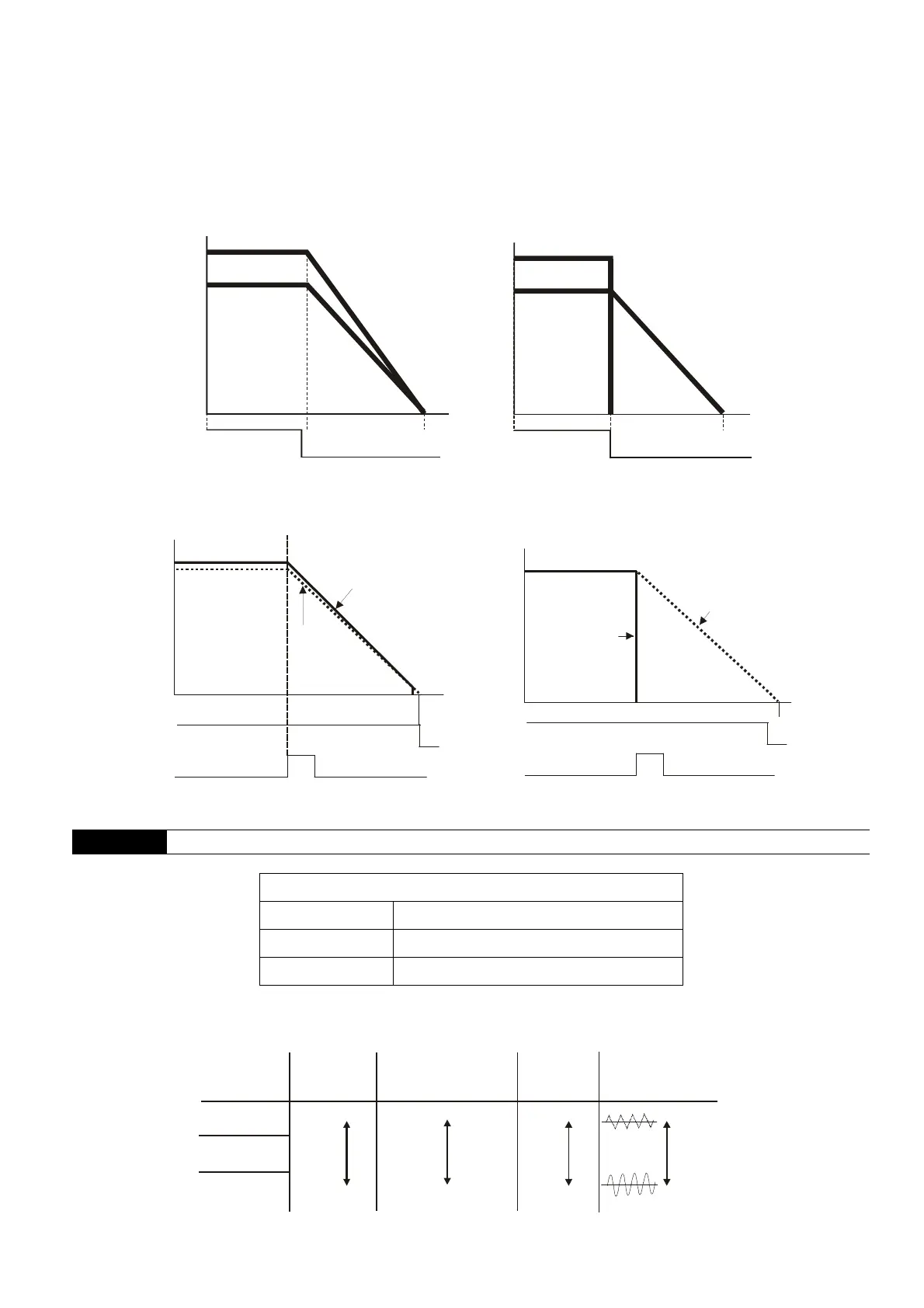

02.03

PWM Carrier Frequency Selections

Unit: 1

115V/230V/460V Series

Power 0.25 to 5hp (0.2kW to 3.7kW)

Setting Range 2 to 12 kHz

Factory Setting 8 kHz

This parameter determines the PWM carrier frequency of the AC motor drive.

2kHz

8kHz

12kHz

Carrier

Noise

Noise or leakage

current

Heat

Dissipation

Current

Wave

Significant

Minimal

Significant

Minimal

Minimal

Significant

Minimal

Significant

Loading...

Loading...