Revision 2016/03, 6ELE, V1.14

4-61

06.05

Over-Torque Detection Time (OL2) Unit: 0.1

Settings 0.1 to 60.0 sec Factory Setting: 0.1

This parameter sets the time for how long over-torque must be detected before “OL2” is displayed.

06.06

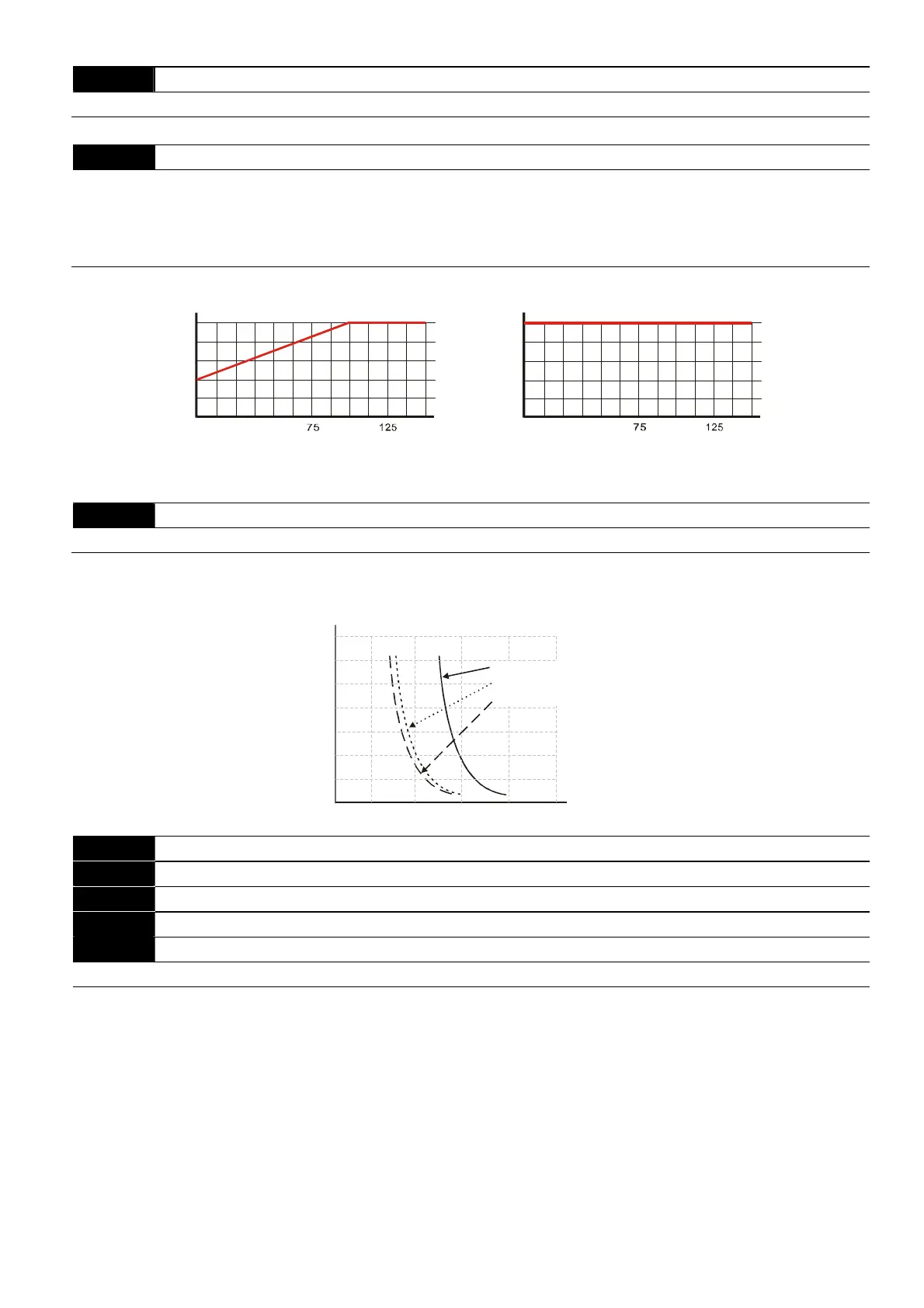

Electronic Thermal Overload Relay Selection (OL1)

Factory Setting: 2

Settings 0 Operate with a Standard Motor (self-cooled by fan)

1 Operate with a Special Motor (forced external cooling)

2 Operation disabled

This function is used to protect the motor from overloading or overheating.

40

20

60

80

25 50

rated frequency of the motor %

rated current of the motor%

Standard motor

(self-cooled by fan)

rated frequency of the motor %

rated cur rent of the m oto r%

Special Motor

(forced external cooling)

25 50

40

20

60

80

100

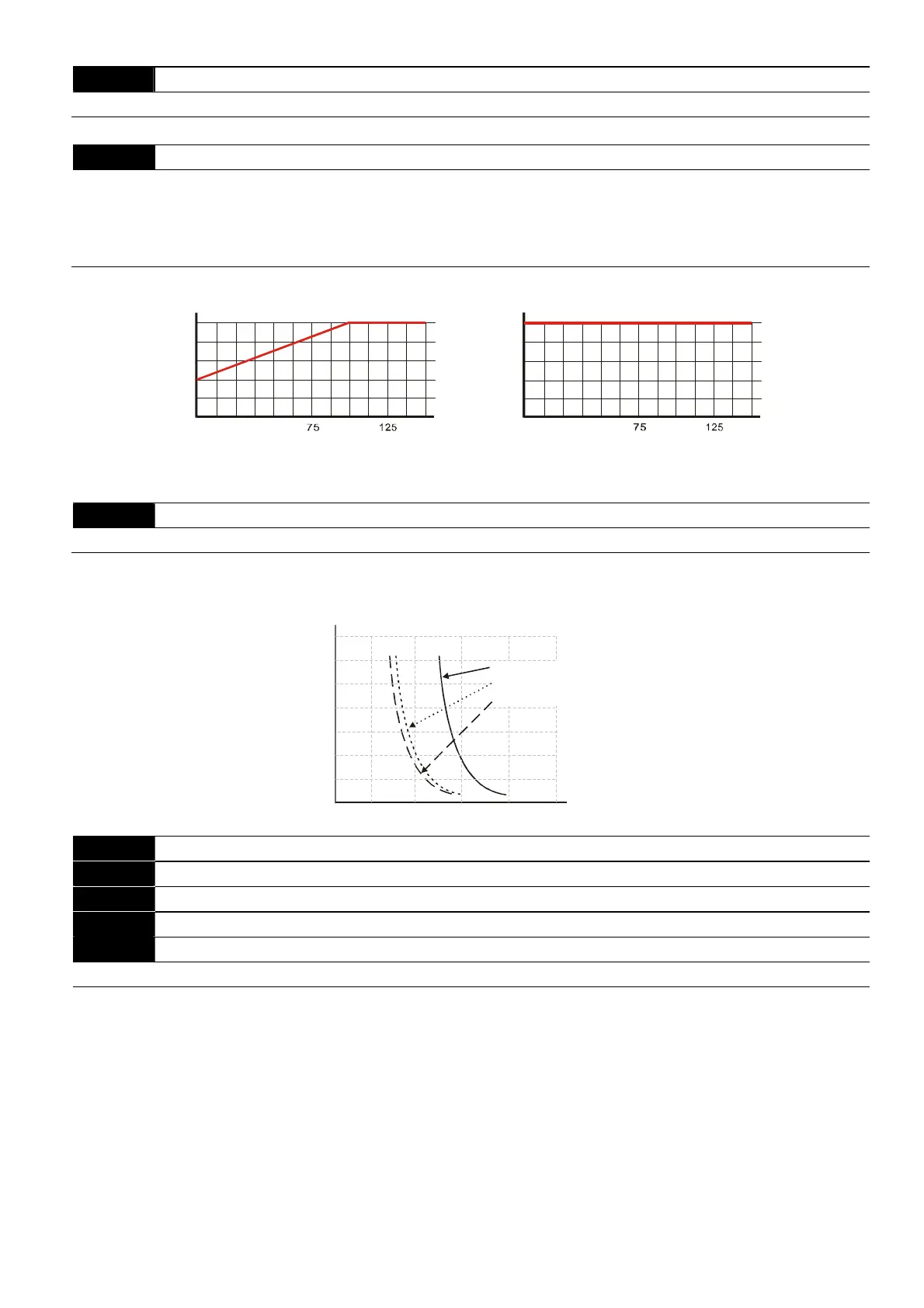

06.07

Electronic Thermal Characteristic Unit: 1

Settings 30 to 600 sec Factory Setting: 60

The parameter determines the time required for activating the I

2

t electronic thermal protection function. The

graph below shows I

2

t curves for 150% output power for 1 minute.

350

10Hz

5Hz

300

250

200

150

100

50

time (seconds)

Load

06.08 Present Fault Record

06.09 Second Most Recent Fault Record

06.10 Third Most Recent Fault Record

06.11 Fourth Most Recent Fault Record

06.12 Fifth Most Recent Fault Record

Factory Setting: 0

Readings 0 No fault

1 Over-current (oc)

2 Over-voltage (ov)

3 IGBT Overheat (oH1)

4 Reserved

5 Overload(oL)

6 Overload (oL1)

7 Motor Overload (oL2)

8 External Fault (EF)

9 Current exceeds 2 times rated current during accel.(ocA)

Loading...

Loading...