Chapter 4 Parameters|

||

|

4-38 Revision 2016/03, 6ELE, V1.14

From the table, we see that the PWM carrier frequency has a significant influence on the electromagnetic

noise, AC motor drive heat dissipation, and motor acoustic noise.

The PWM carrier frequency will be decreased automatically by the ambient temperature and output current of

the AC motor drives. It is used to prevent AC motor drive overheat and extend IGBT’s life. Therefore, it is

necessary to have this kind of protection method. Take an example of 460V models, assume that the carrier

frequency is 12kHz, ambient temperature is 50 degrees C with single AC motor drive. If the output current

exceeds 80% * rated current, the AC motor drive will decrease the carrier frequency automatically by the

following chart. If output current is around 100% * rated current, the carrier frequency will decrease from 12k

Hz to 8k Hz.

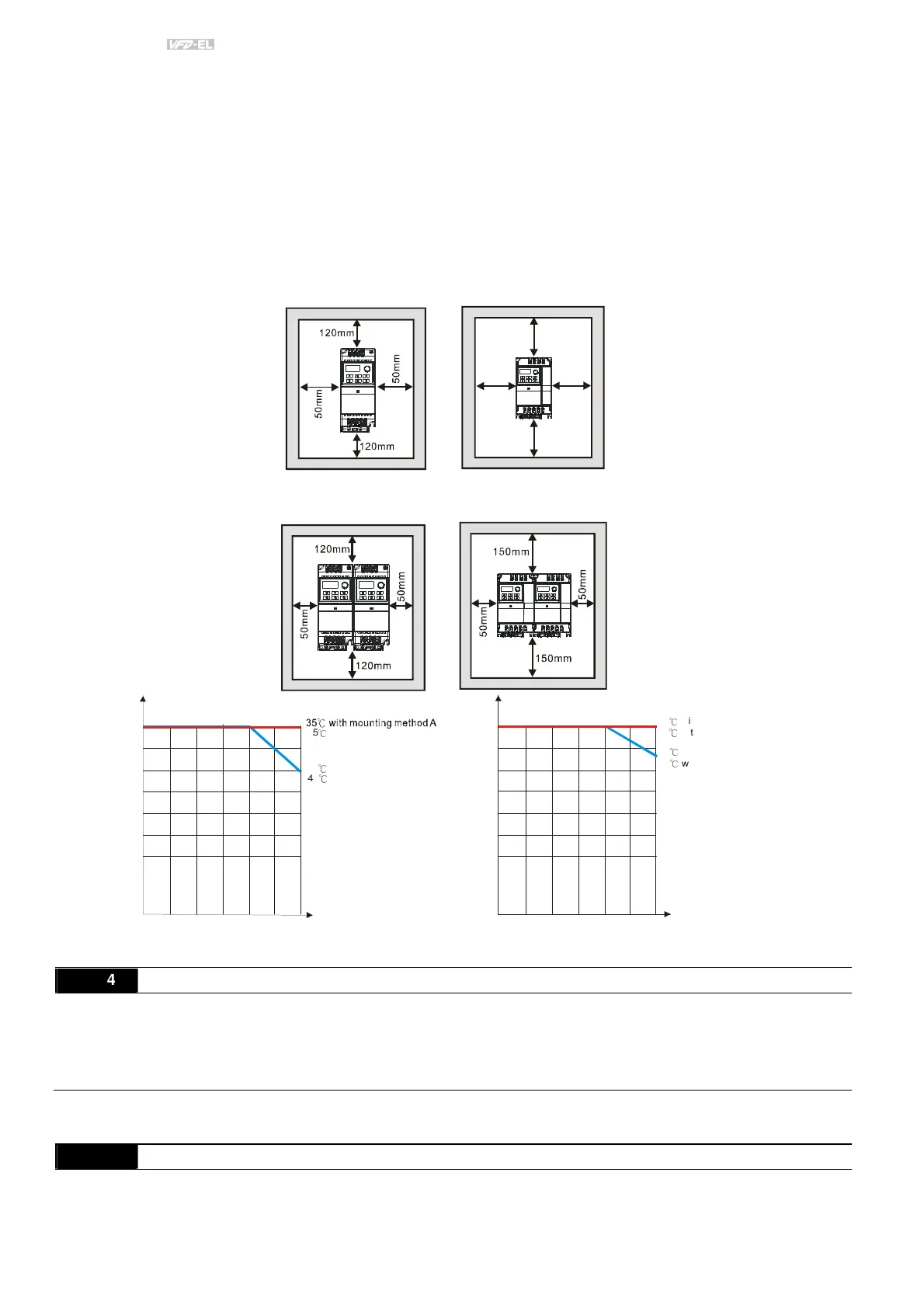

Mounting method

Frame B

Frame A

Frame A

40%

50%

60%

80%

90%

100%

70%

Carrier

2kHz

4kHz 8kHz

10kHz

12kHz

6kHz

50 with mounting method A

℃

40 with mounting method B

℃

25 with mounting method B

℃

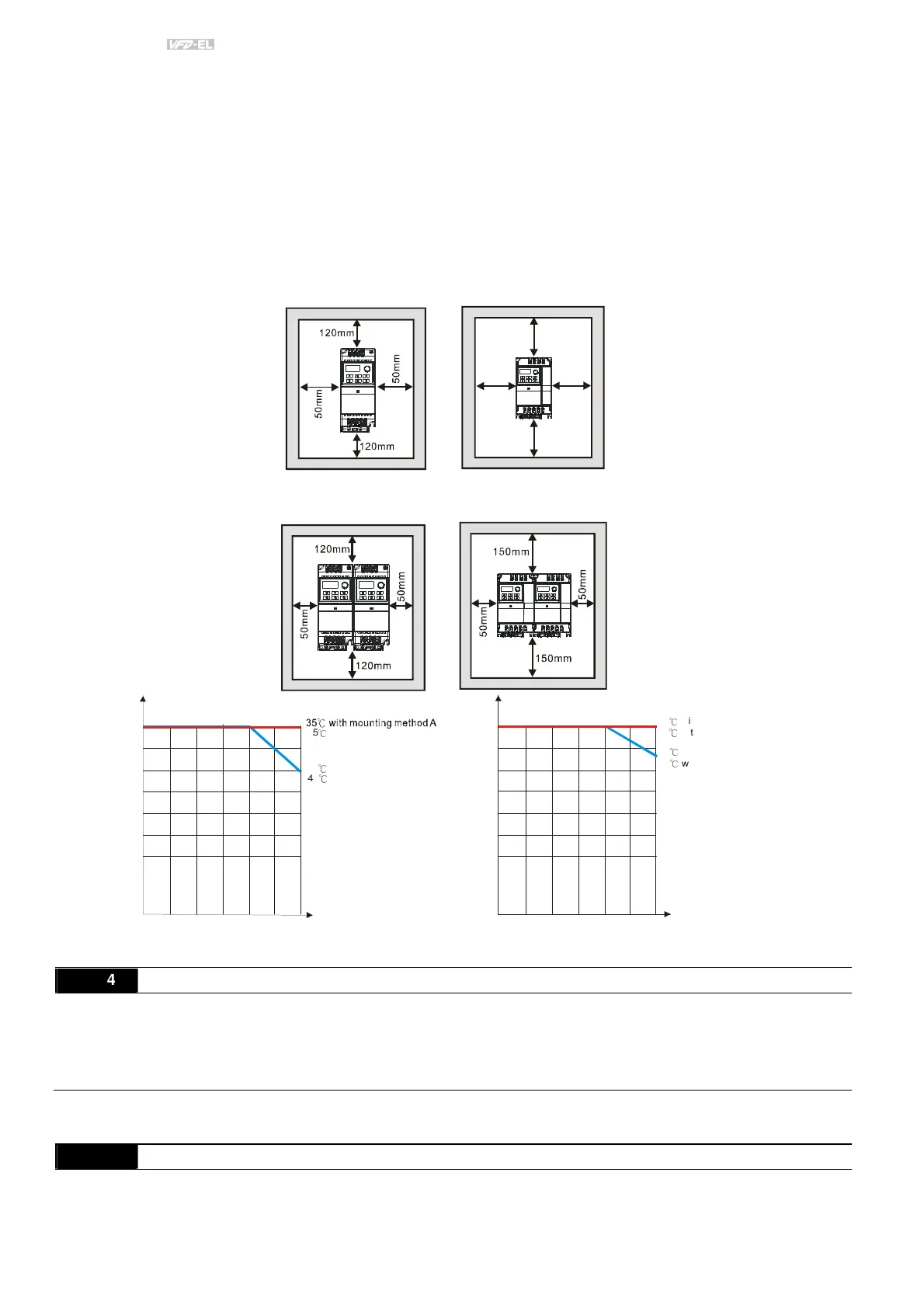

40%

50%

60%

For 115V/230V Series

80%

90%

100%

2kHz

4kHz 8kHz

10kHz

12kHz

6kHz

70%

Carrier

50 with mounting method A

℃

40 with mounting method B

℃

35 with mounting method A

℃

25 with mounting method B

℃

02.04

Motor Direction Control

Factory Setting: 0

Settings 0 Forward/Reverse operation enabled

1 Reverse operation disabled

2 Forward operation disabled

This parameter is used to disable one direction of rotation of the AC motor drive direction of rotation.

02.05

The source of Power-On command and Running command modifies the operating control of the VFD

Factory Setting: 1

Settings 0 Start running when Power is on.

1 Don’t run when Power is on

Loading...

Loading...