AX-Series Motion Controller Instructions Manual Chapter 2

473

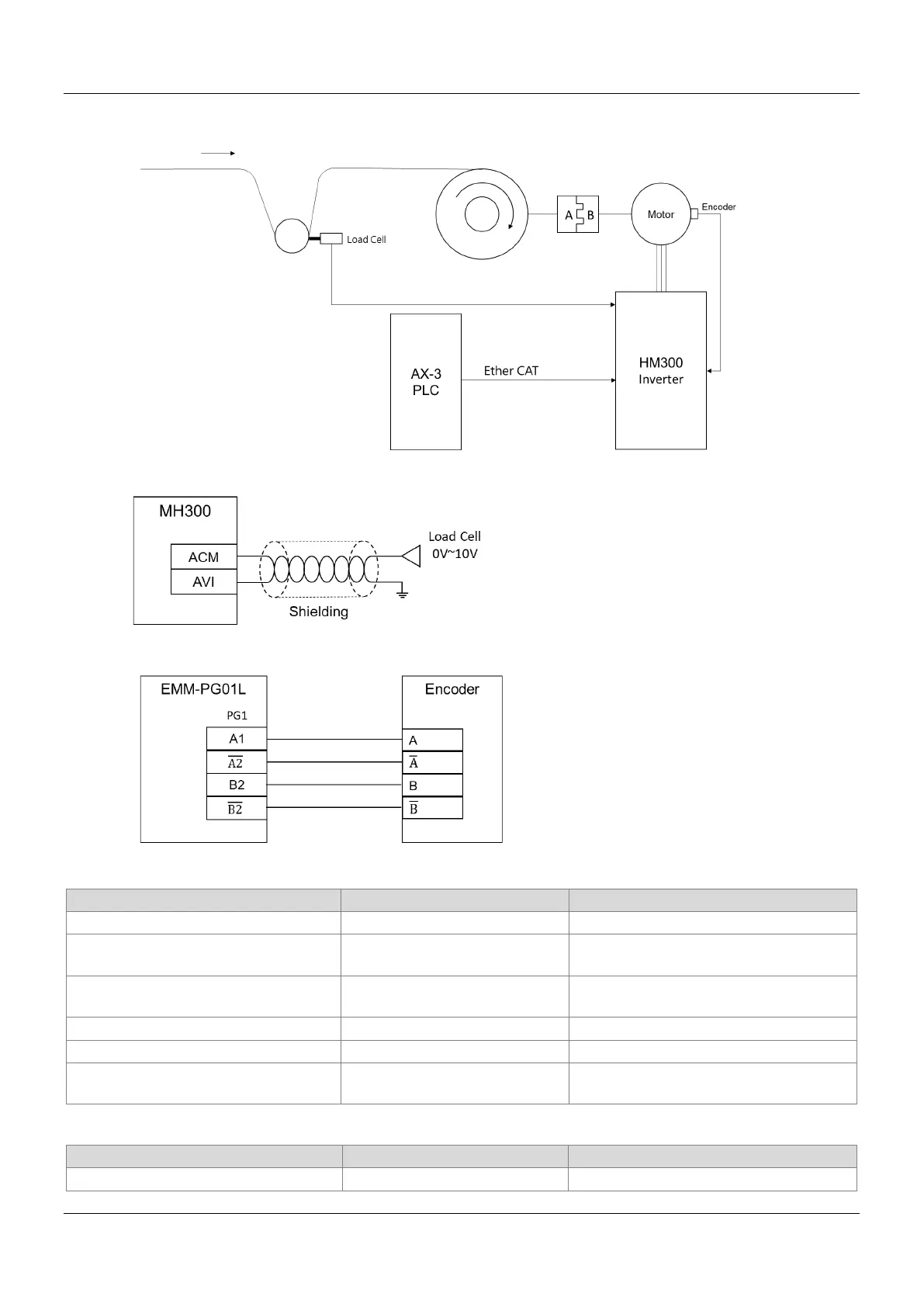

Example 2: This example shows how to use the TensionCloseLoop_TorqueMode (Tension closed-loop, torque mode)

mode. Refer to the following device architecture:

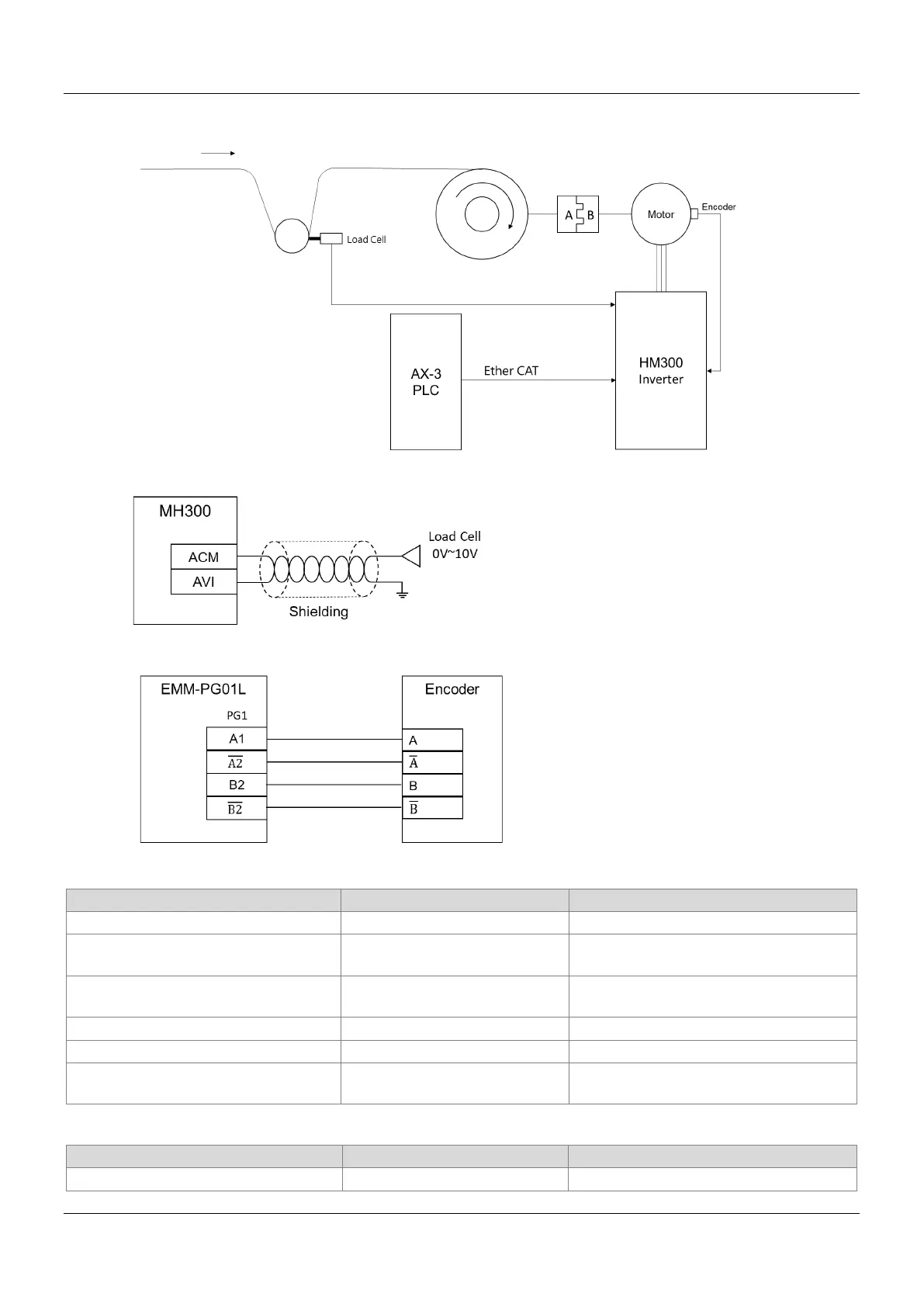

Load Cell Wiring Diagram.

EMM-PG01L Wiring Diagram

R2R_Configuration Parameters

Name Value Description

TensionCloseLoop_TorqueMode

Set the tension closed-loop torque mode

A(uiGearRatio_WindingSide)

200

Set the mechanical gears on the winding

B(uiGearRatio_MotorSide)

100

Set the mechanical gears on the motor side

B

lrTensionTargetMax 350 Maximum tension value (N)

PID_TargetSource AVI

The hardware signal is the Load Cell

voltage signal of the tractor (Pitch roller).

R2R_RollDiameter Parameters

Set the roll diameter source to line speed

Loading...

Loading...