Milling Quality Problems

138

5. Troubleshooting

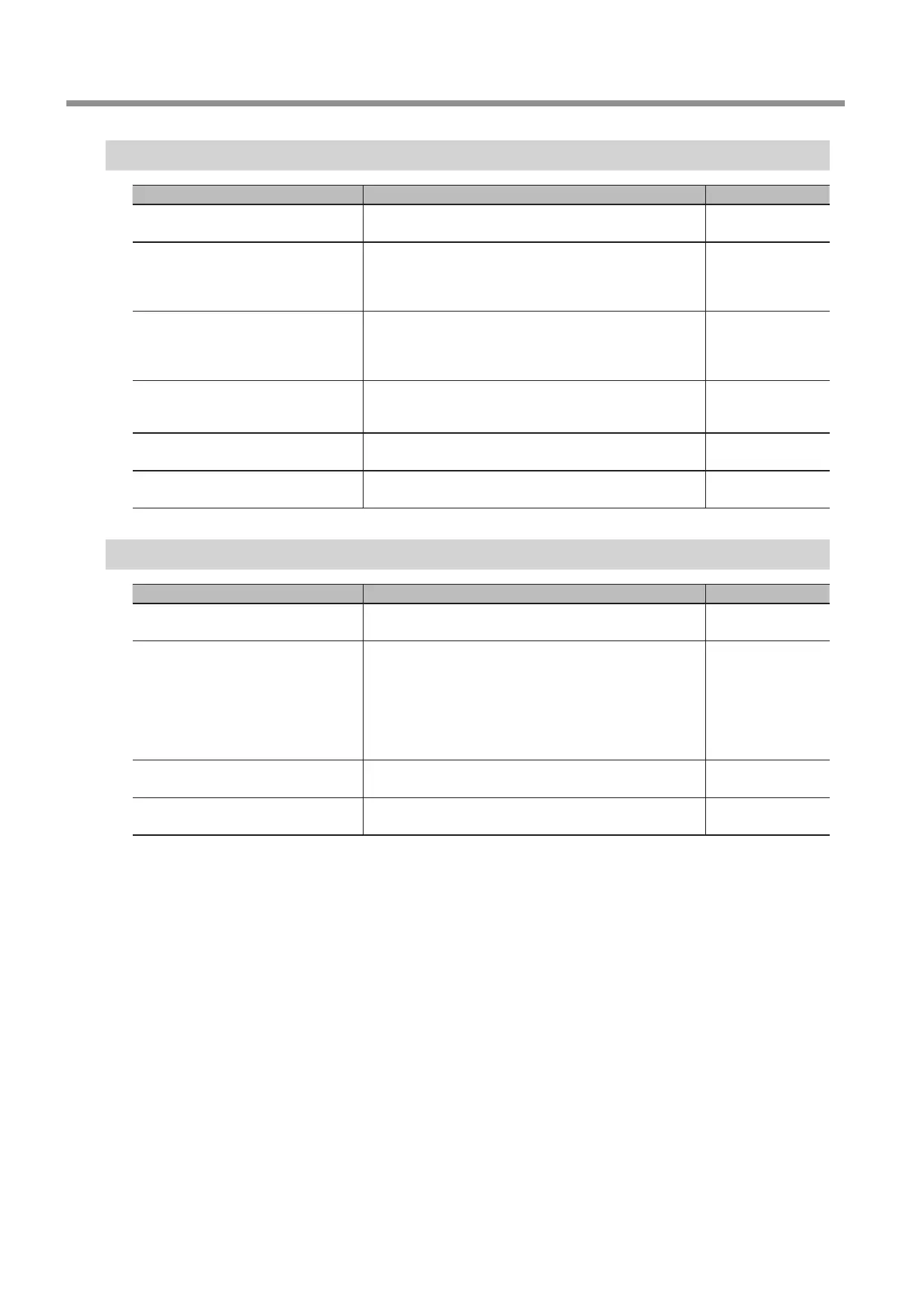

Chipping Occurs (Edges of Milling Products Become Chipped)

Check Action Refer to

Is the installation base of the

machine secure?

The vibration from cutting can shake the installation base. —

Is the workpiece rmly secured in

place?

Check the mounting condition of the workpiece. Fasten the

workpiece in place securely so that it will not slip out of place

or come loose because of milling bur pressure or vibration

during milling.

—

Is the milling bur worn? If the same milling bur is used for milling for a long period

of time, it will become worn and aect milling results. Try

replacing the milling bur with a new one. The work time of the

milling bur can also be managed in VPanel.

—

Is the collet deformed? The collet may be deformed if the tip of the spindle strikes the

rotary axis, etc., or if the spindle is locked. Replace the collet

if it is deformed.

—

Is the thickness specied in the

milling data excessively thin?

If the workpiece thickness is excessively thin, chipping is likely

to occur. Check the shape specied in the milling data.

Are the milling conditions too

strict?

Strict milling conditions may aect milling results. Review the

CAM milling conditions.

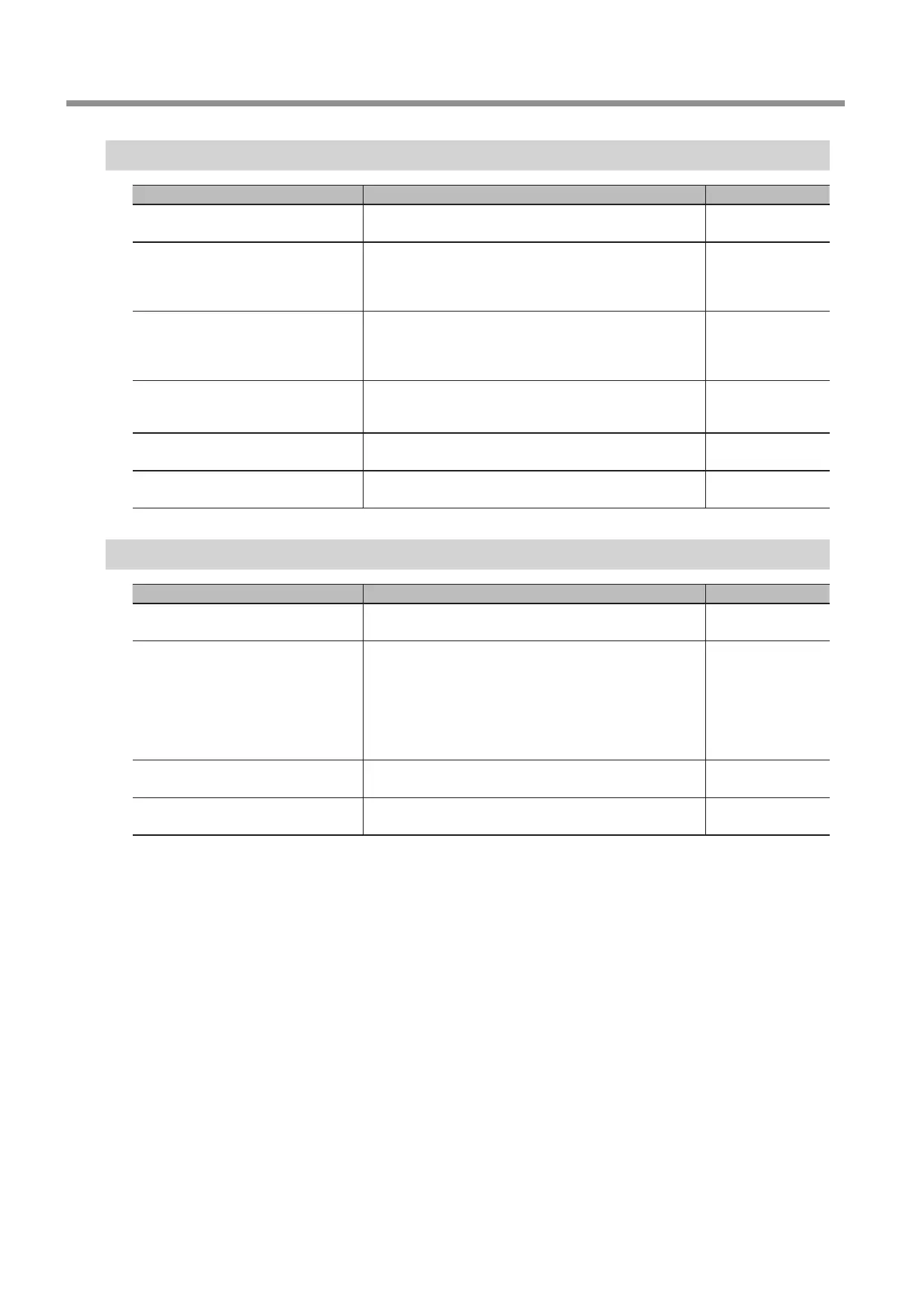

A Hole Opens in the Milling Results

Check Action Refer to

Does the milling bur diameter match

the CAM settings?

Check the CAM's milling bur settings. —

Is the machine out of correction? The origin point may become out of position due to prolonged

use or relocating the machine, which can aect milling results.

Perform automatic correction. If the expected results cannot

be obtained even after performing automatic correction,

perform manual correction. With manual correction, changing

the Z value in the + direction in Origin point may improve the

situation.

—

Are the milling conditions too

strict?

Strict milling conditions may aect milling results. Review the

CAM milling conditions.

—

Is the thickness specied in the

milling data excessively thin?

The nish thickness of milled products needs to be 0.8 mm or

more. Check the thickness specied in the milling data.

—

Loading...

Loading...