Periodic Care and Maintenance

Correcting the Milling Machine

The accuracy of the milling machine may change if it is used for a long period of time or the surrounding environment changes�

Automatic correction corrects the positions of the rotary axis and ATC magazine�

Situations Requiring This Work

• When the milling position is misaligned

• When symptoms such as a line of level dierence or a hole in the Z direction occurs in the milling results

• When the machine is moved to a dierent location

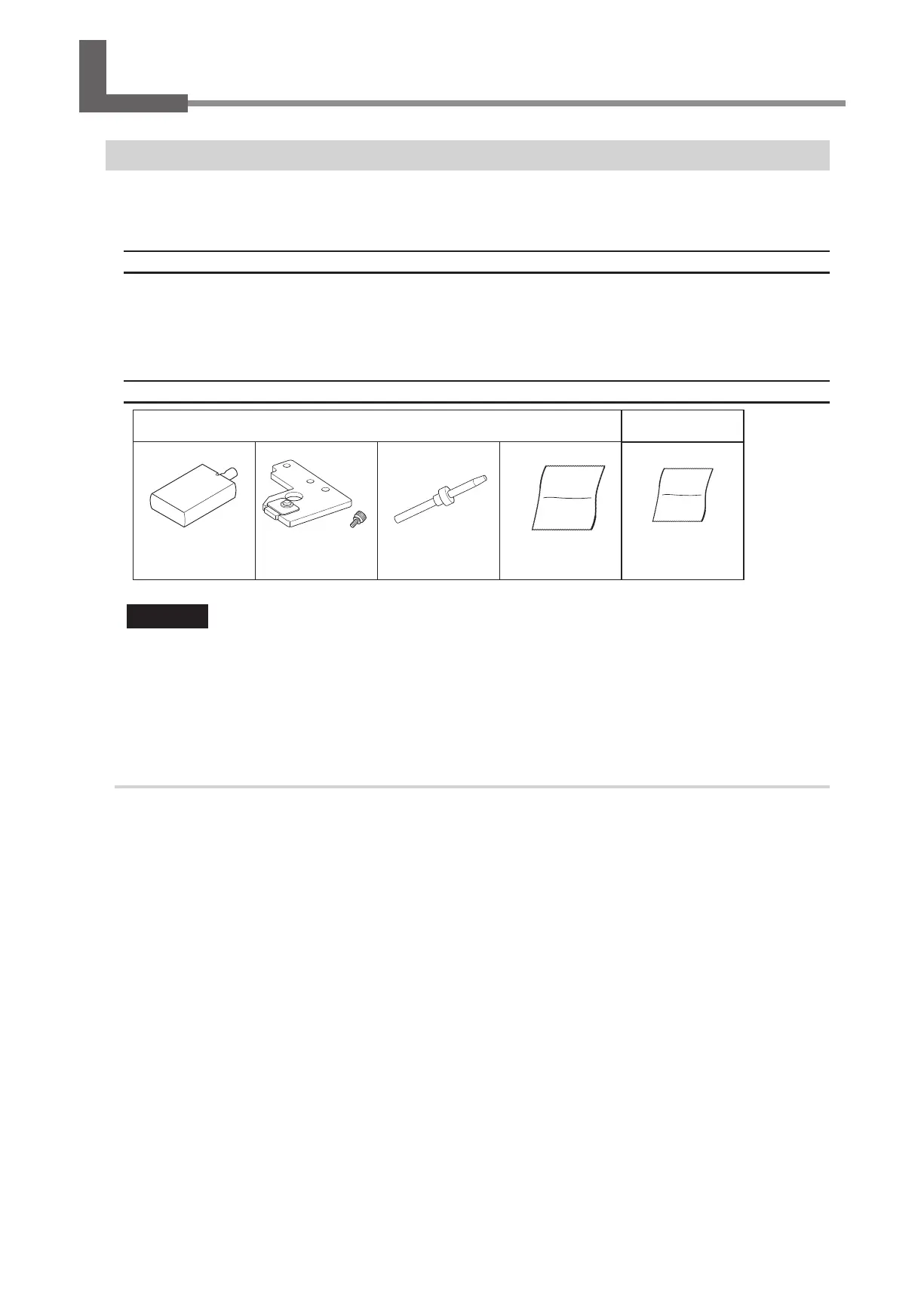

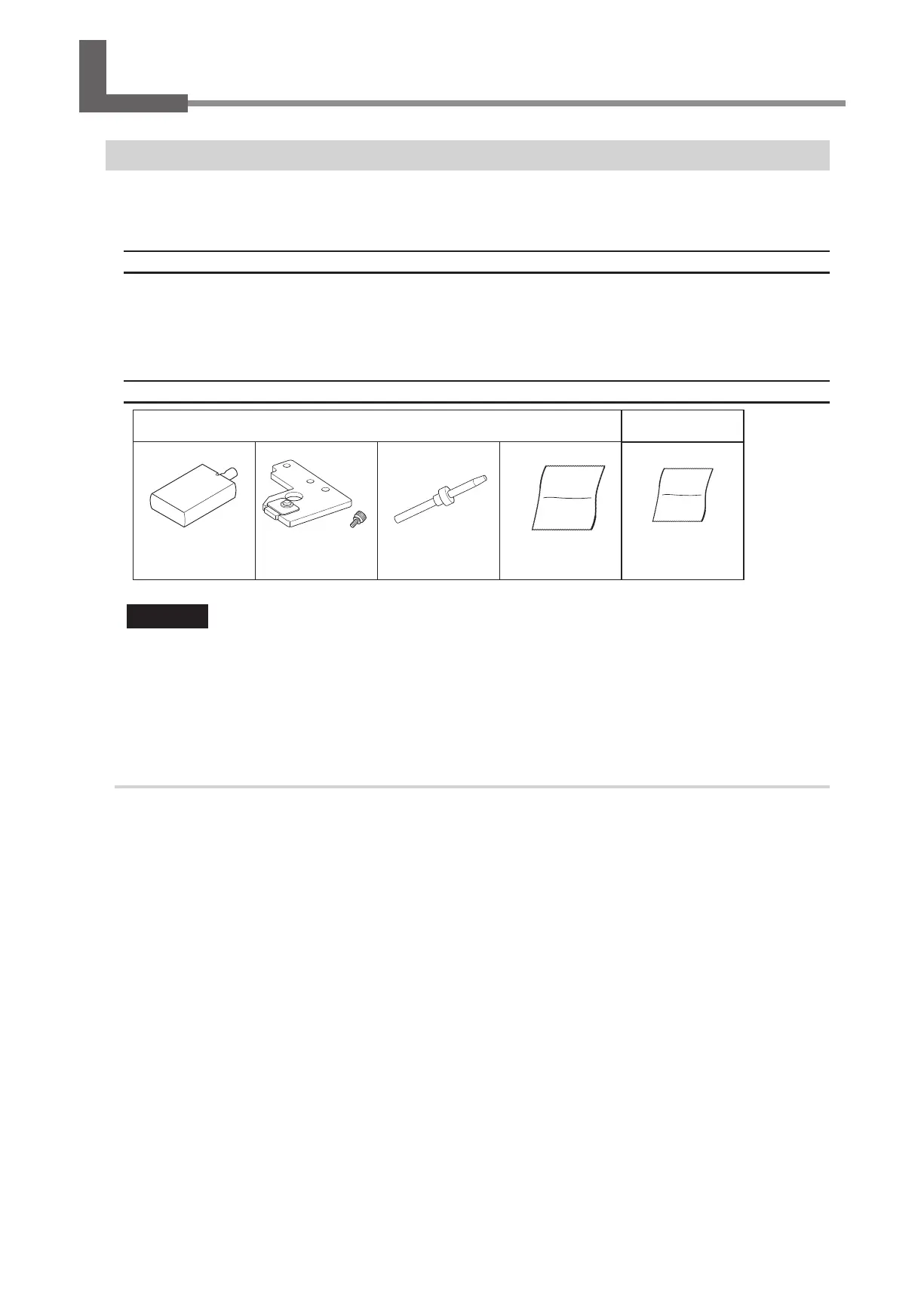

Required Tools

Included items

Commercially

available item

Rotary axis correction jig

ATC magazine

correction jig/A screw

Detection pin for

correction

Cloth for care and

maintenance

Clean, dry cloth

Important

Handle the detection pin for correction and the dummy pin separately to be absolutely sure that you do not

confuse them.

If the detection pin for correction is used as the dummy pin even once, the detection pin for correction cannot be used to provide

proper correction� If for some reason the detection pin for correction is used as the dummy pin, a new detection pin for correction

will be necessary� Contact your authorized DGSHAPE Corporation dealer or access our website (http://www�dgshape�com/)�

1.

Clean the detection point for use during correction.

A

Open the front cover.

B

Remove all the milling burs.

When the milling bur is dicult to remove, using the milling bur removal jig.

"

C

If the inside of the machine is wet, wipe it o with a clean, dry cloth.

56

3. Maintenance

Loading...

Loading...