120

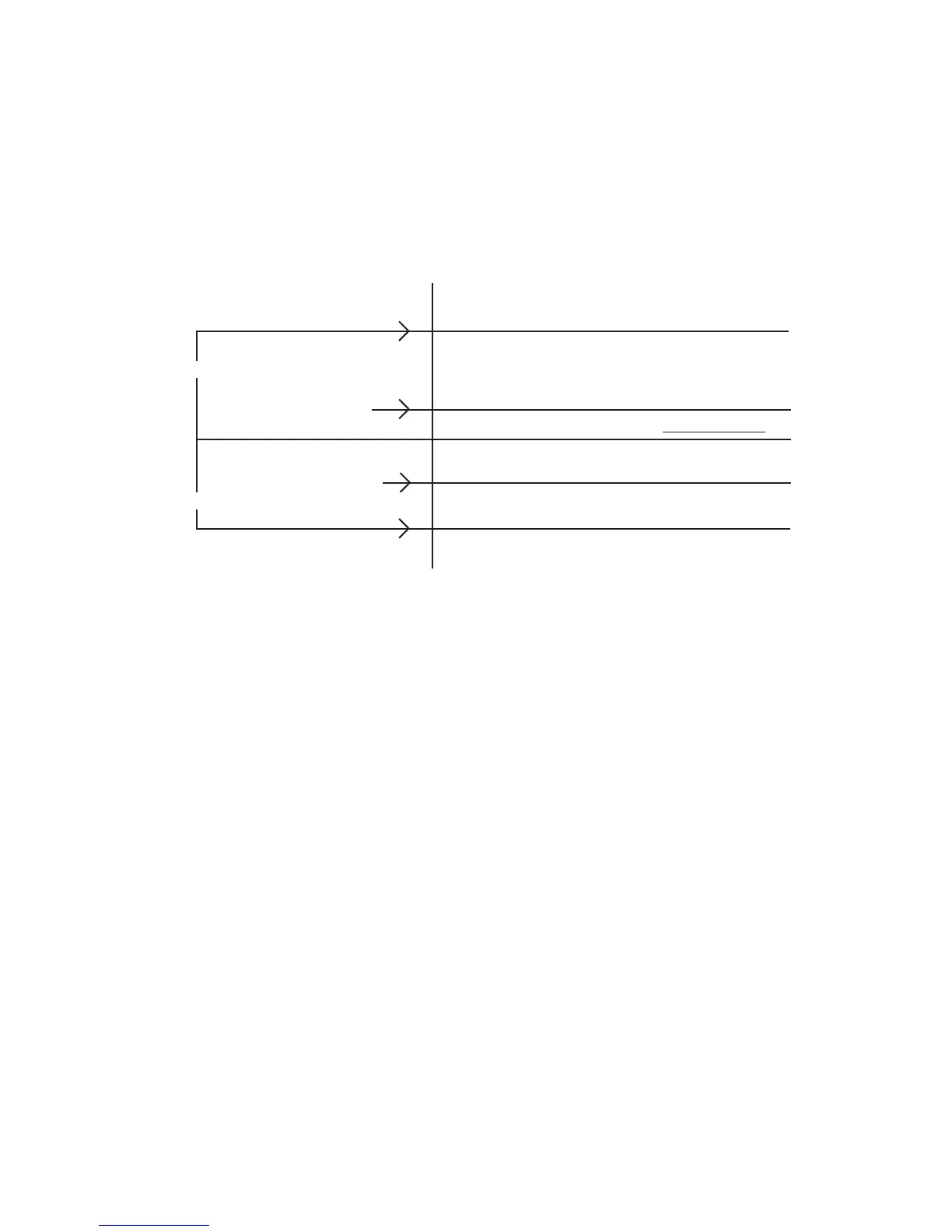

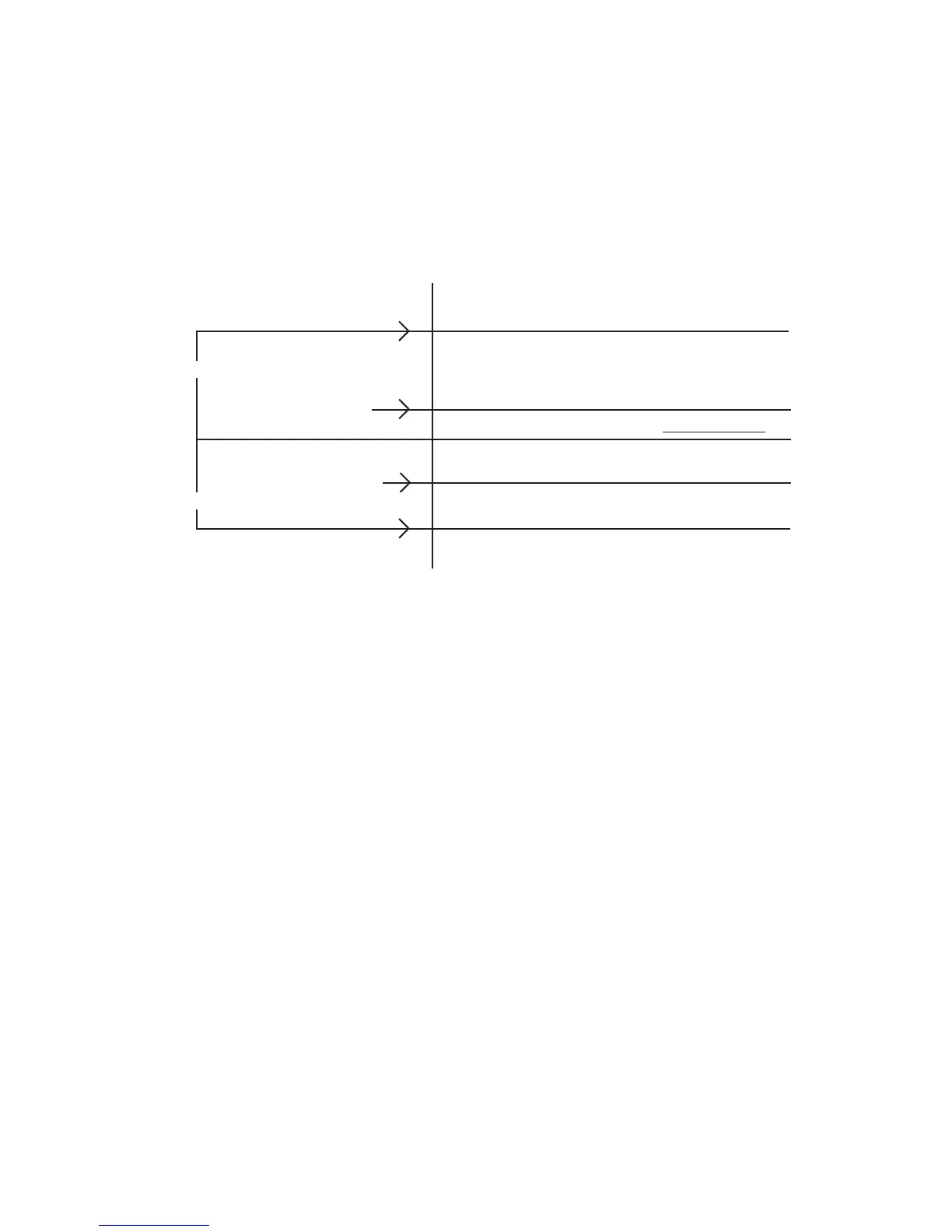

The relationship of these parameters can be seen in the sequencer control strategy diagram shown below.

Difference Above Setpoint

Stages added using the fast delay timer

Load Bandwidth

Stages added using the normal delay timer

Load Deadband

No stages added or removed

Control Setpoint

No stages added or removed

Unload Deadband

Unload Bandwidth

Stages added using the fast delay timer

Difference Below Setpoint

Sequencing Commands

The sequencer controls compressors by sending sequencing commands. These commands are transferred locally

to compressors on the master or via the communications link to remotes. The commands and their function are as

follows:

SEQUENCE STOP- The SEQUENCE STOP command is sent to cause a compressor to form an

automatic stop. The compressor remains on-line and available for the nextsequencer operation. If

the anti-recycle timer on the compressor has not expired, the compressor will continue running in

the Hot Standby state at zero percent capacity.

TRIM-The TRIM command is sent to the compressor that has been chosen to become the trim

machine. This compressor will make capacity adjustments to control the load using automatic

control. If the compressor is stopped and on-line, the TRIM command will perform a

sequenced start. Bandwidths and deadbands are sent to a compressor when the TRIM command

is sent. Also, all time proportional control parameters are transferred to recip compressors with

this command.

FULL LOAD - When FULL LOAD is received, a compressor will adjust to full

capacity and hold that condition. If a compressor is stopped and on-line, the

FULL LOAD command will perform a sequenced start.

Sequencer Control Strategy

Loading...

Loading...