A1000 38 532210 04 - Rev.A

39

2

6

12

Nm

Translation of the original instructions

ENGLISH

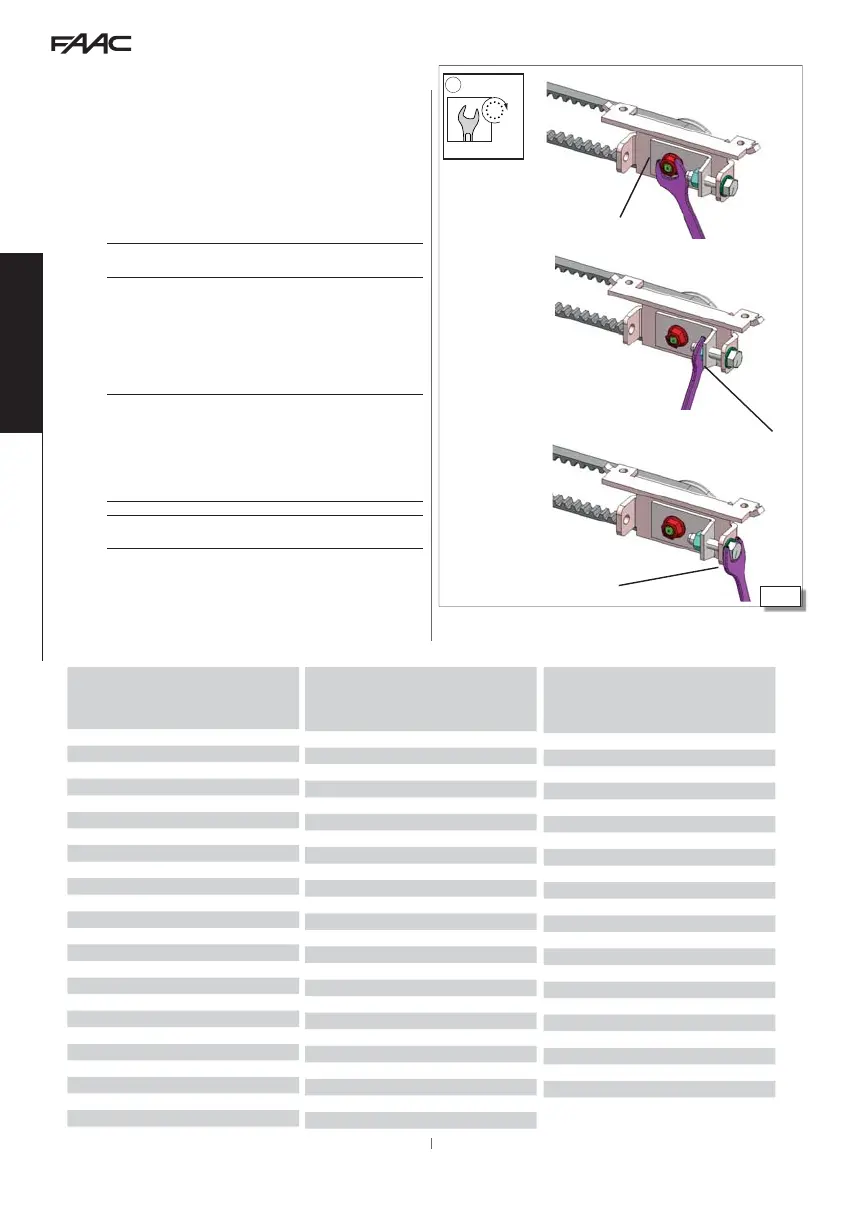

RH single leaf

Pulley centre dis-

tance (I)

Belt length f

1000 2140 17

1080 2300 19

1160 2460 20

1240 2620 22

1320 2780 23

1400 2940 24

1480 3100 26

1560 3260 27

1640 3420 29

1720 3580 30

1800 3740 31

1880 3900 33

1960 4060 34

2040 4220 35

2120 4380 37

2200 4540 38

2280 4700 40

2360 4860 41

2440 5020 42

2520 5180 44

2600 5340 45

2680 5500 47

2760 5660 48

2840 5820 49

Double leaf

Pulleys centre

distance (I)

Belt

length

f

1250 2640 22

1320 2780 23

1390 2920 24

1460 3060 25

1530 3200 27

1600 3340 28

1670 3480 29

1740 3620 30

1810 3760 31

1880 3900 33

1950 4040 34

2020 4180 35

2090 4320 36

2160 4460 38

2230 4600 39

2300 4740 40

2370 4880 41

2440 5020 42

2510 5160 44

2580 5300 45

2650 5440 46

2720 5580 47

2790 5720 49

LH single leaf

Pulleys centre

distance (I)

Belt

length

f

1000 2140 17

1080 2300 19

1160 2460 20

1240 2620 22

1320 2780 23

1400 2940 24

1480 3100 26

1560 3260 27

1640 3420 29

1720 3580 30

1800 3740 31

1880 3900 33

1960 4060 34

2040 4220 35

2120 4380 37

2200 4540 38

2280 4700 40

2360 4860 41

2440 5020 42

2520 5180 44

2600 5340 45

2680 5500 47

2760 5660 48

2840 5820 49

9 A1000 belt tensioning (measurements in mm)

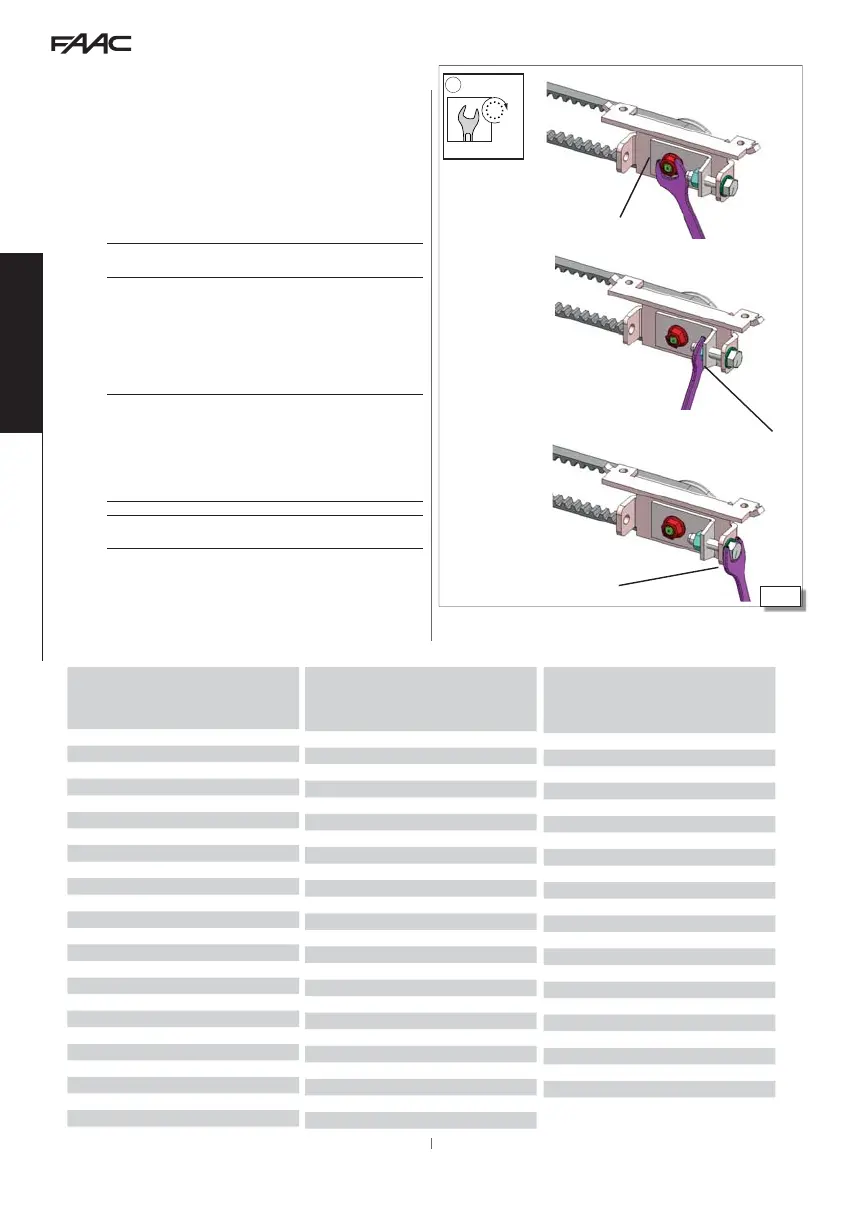

11.2 BELT TENSIONING

1. To tension the belt correctly, proceed as follows.

2. Loosen the nut 39 - .

3. Adjust the screw and nut 39

- to tension or slacken the belt.

4. Attach a 1 kg weight in the centre of the lower section of the belt.

5. Measure the arrow f and adjust the screw 39

- using a hex

spanner until obtaining the measurement specified in the table.

6. After adjustment, tighten the screw 39

-.

7. Carry out a few cycles and make sure the belt remains in its seat

flush with the pulley on the main motor and on the return pulley.

!

Caution - make sure that the belt remains flush with the pulleys of the

main motor and the return pulley.

8. If the belt is not flush with the pulleys, loosen the fastening screws

of the return pulley bracket 39

-

9. Rotate the return pulley bracket clockwise.

10. Tighten the return pulley bracket fastening screws.

11. Perform a few cycles again and check that the belt remains flush

with the pulley.

!

Close the door and ensure:

- the closing point between the two leaves matches with the centre line

of the support profile.

- complete opening and closing is possible.

In case of deviation, check the position and correct connection of the

belt fittings.

!

When the belt is new tensioning adjustment must be repeated after the

first 100 cycles.

Loading...

Loading...