Chapter 4 Installation and Wiring

PAGE 4-48

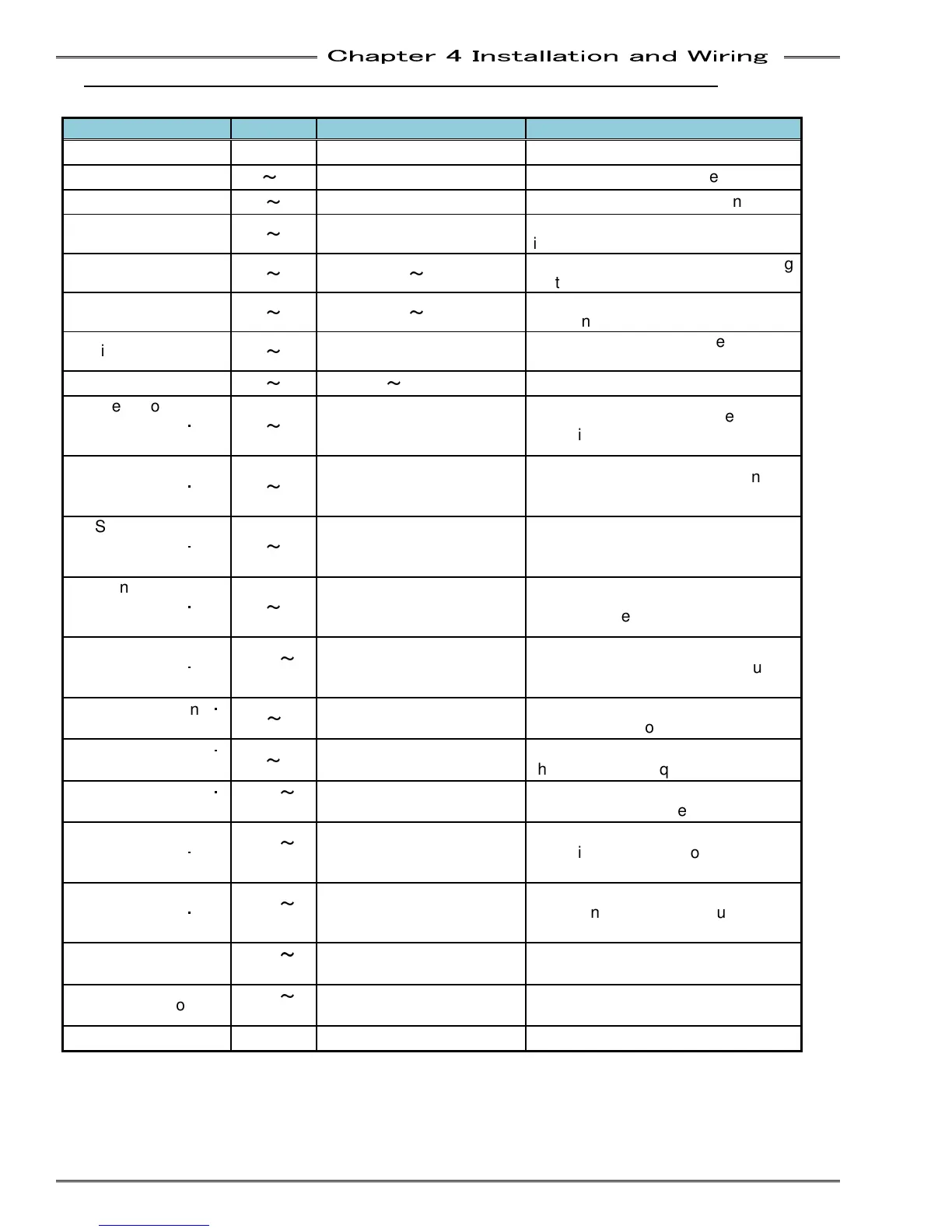

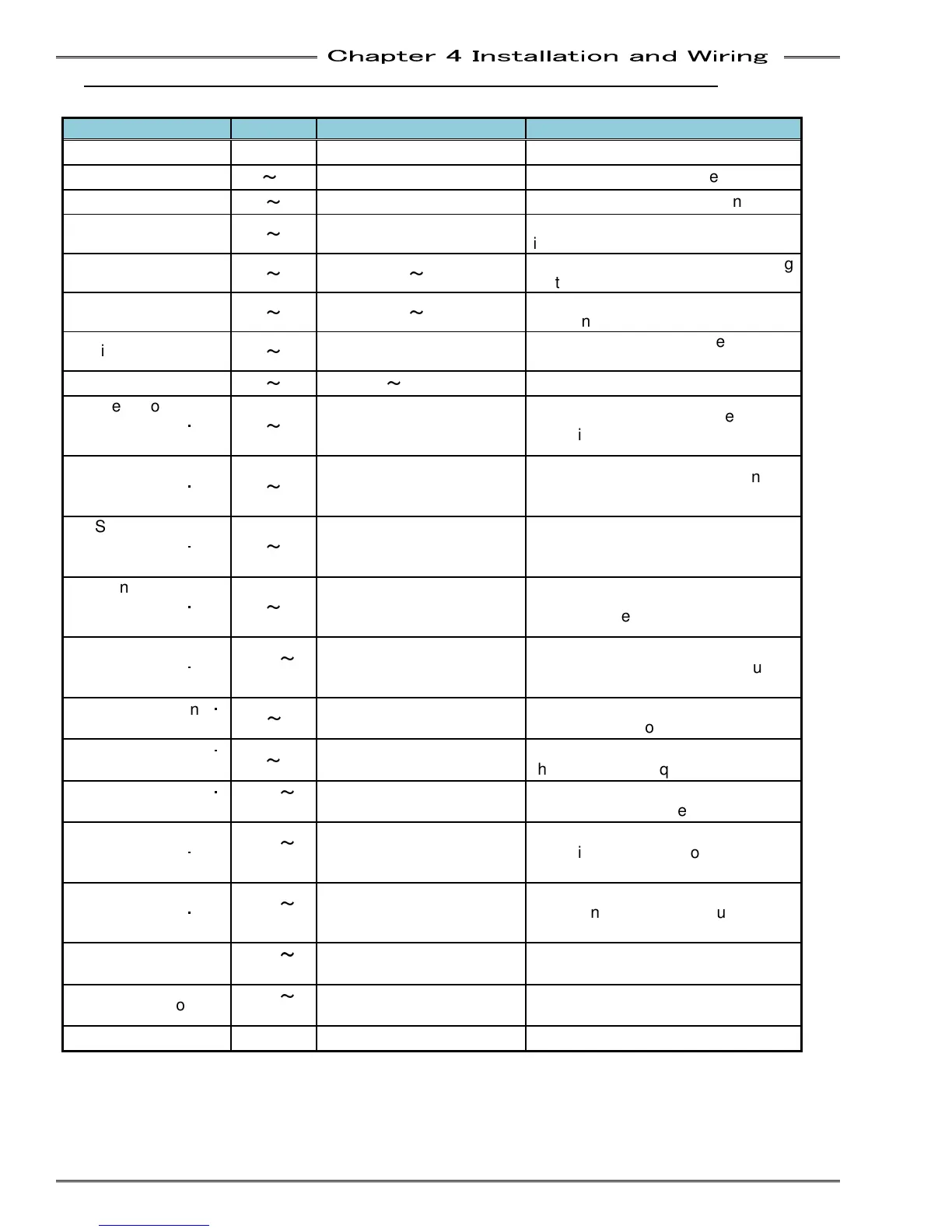

4-8-3 RS-232C Fastening Result Output Data Item List (Single System)

Fastening data items (for the Single System) are as follows;

STX 1 02H Start of text.

Date

2

~

11

2013/05/12 Date of execution of fastening

Time

12

~

19

12:34:56 Time of execution of fastening

ID Data

20

~

51

ABCDEF

32 letters at maximum (NULL is

indicated if this is not set)

Spindle No.

52

~

53 1

~

32

Spindle No. of the controller during

fastening

PAR No.

54

~

55 1

~

32

Parameter No. used during the

fastening

Spindle Judgment

56

~

59

See previous page.

Pass/fail or error judgment of the

fastening operation

Spdl. Cycle Count

60

~

67 0

~

9999999

Cycle count value of the MFC Unit

Peak Torque

(Judgment

・

Occurrence)

68

~

75

12.34

Peak torque value generated during

fastening

Final Torque

(Judgment

・

Occurrence)

76

~

83

12.34

Final torque value at the end of

fastening

SNUG Torque

(Judgment

・

Occurrence)

84

~

91

12.34

Torque value when SNUG torque

was detected

Final Angle

(Judgment

・

Occurrence)

92

~

99

123.4

Rotating angle value at the end of

fastening (Degrees)

Differential Angle

(Judgment

・

Occurrence)

100

~

107

-12.3 Differential judgment angle value

Rate 1 (Judgment

・

Occurrence)

108

~

116

1.234

Rate 1 value from Start torque to

the rate 1 End torque (TQ/Deg)

Rate 2 (Judgment

・

Occurrence)

118

~

126

0.123

Rate 2 value from Start torque to

the rate 2 End torque (TQ/Deg)

Rate 3 (Judgment

・

Occurrence)

128

~

136

0.123

Rate 3 value from Start torque to

the rate 3 End torque (TQ/Deg)

1st Time

(Judgment

・

Occurrence)

138

~

146

1.234

Fastening time from the start of

fastening to the point of detection of

the 1st torque (angle)

2nd Time

(Judgment

・

Occurrence)

148

~

156

2.345

Fastening time from the point of

detection of the 1st torque (angle)

to the end of fastening

Cycle Time

158

~

164

3.567

Fastening time from the start to end

of fastening

Load Factor

166

~

169

12

Percent of load rate during the

fastening operation

ETX 170 03H End of text.

Loading...

Loading...