Chapter 7 Fastening Instructions

PAGE 7-32

7-3-2 Torque Rate Check

The AFC3000 System is capable of performing 3 torque rate calculations. The Point-to-Point torque rate

method performs the calculation based upon completing a step of the process and then calculating the

rate for the full duration of that step. If the calculated rate falls outside of the high / low rate limits for that

step, the fastening operation will end and a REJECT output.

The chart below identifies the different areas that torque rate can be calculated. Each Torque Rate is

calculated by dividing the change in torque during the specific period by the change in angle.

Example: 25Nm / 100deg. = 0.25 Nm/Deg. (rate)

NOTE: Setting any of the Torque Rate START POINTS above the FASTENING END TORQUE will

eliminate the torque rate calculation for that stage.

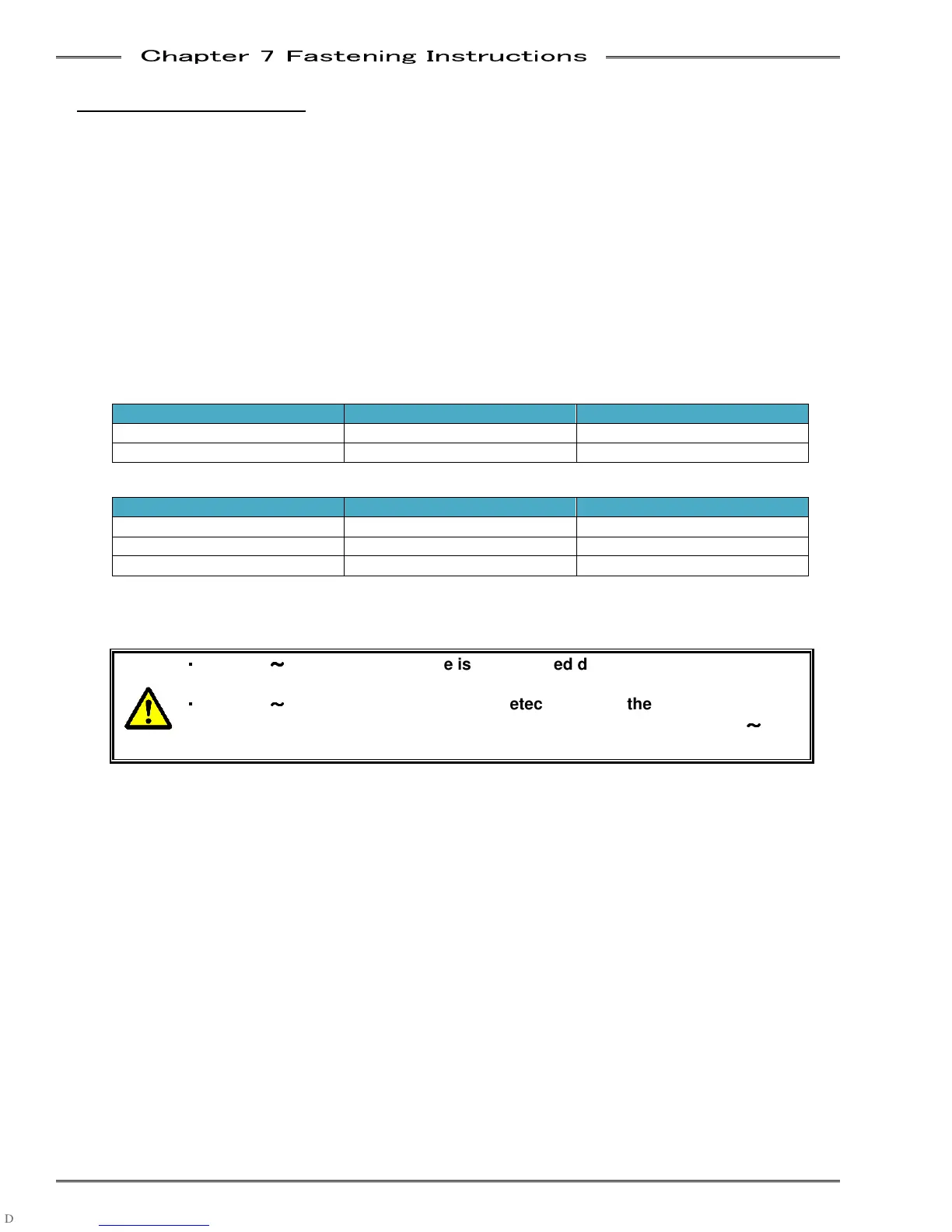

Torque Rate Calculation Areas (Typical for 1 or 2 step)

(3rd Rate Start and End Torque set above FASTENING END TORQUE

)

1ST TORQUE RATE 1ST RATE START TORQUE 1ST RATE END TORQUE

2ND TORQUE RATE 2ND RATE START TORQUE 2ND RATE END TORQUE

Torque Rate Calculation Areas (Typical for 3 step, however can be used on 1 or 2 step)

1ST TORQUE RATE

1ST RATE START TORQUE 1ST RATE END TORQUE

2ND TORQUE RATE

2ND RATE START TORQUE

2ND RATE END TORQUE

3RD TORQUE RATE

3RD RATE START TORQUE

3RD RATE END TORQUE

For all control operations, the High and Low Torque Rate limits are set by determining the

acceptable limits from a study of known good and bad assemblies.

・

・・

・

If the 1

st

~

~~

~

3

rd

Rate Start Torque is not detected during the fastening, the rate

judgment will not be performed.

・

・・

・

If the 1

st

~

~~

~

3

rd

Rate End Torque is not detected during the fastening, the

torque value which is detected when the fastening ends is judged as 1

st

~

~~

~

3

rd

Rate End Torque.

Loading...

Loading...