Chapter 4 Installation and Wiring

PAGE 4-29

4-6 Connection of External Control Signals

4-6-1 PLC IO Signal (Single System)

IN: Input Signal

OUT: Output Signal NC: Normal Close NO: Normal Open

Pin

Signal Name IN/OUT

Function

・

・・

・

Usage Instruction

1 IN COMMON IN

Input signal common

(

Bi-directional

)

2 STOP IN NC

Signal MUST be active to perform a fastening operation.

When this signal is inactive (off), all controller operation ceases, all spindles in motion

will stop and all communication ports & input/outputs will be disabled.

3 RESET IN NO

When active (on), this signal will clear all spindle data and discrete outputs. A Zero

Check of all load transducers will be completed. During the Zero Check, the CHECK

lamp will illuminate, the READY sig

nal will turn OFF, and the ACCEPT or REJECT

lamp will light to indicate the result of the Zero Check. If the System has been disabled

by an Abnormal output, the System will not return to normal operation until the

Abnormal condition has been corrected, and

this signal has been input for

200~500ms. Do not

input this signal between cycles as part of an automatic cycle due

to the potential for spindle data loss.

4 REVERSE IN NO

The selected spindle will move in the direction opposite of the tightening directi

as long as this signal is activated (on) and maintained

5 START IN NO

The Start

input automatically resets the previous cycle, clears all data to zero, and

initiates the next fastening cycle.

6 BYPASS IN NO

Spindle is ignored as if it does not exist as long as this signal is "ON"

7 SELF CHECK OFF IN NO

When activated (ON) the Self Check of the torque transducer

performed at the start of

the fastening operation will be disabled.

8 PAR SELECT BIT 0

IN NO

These 5 inputs when selected in a binary cod

e is capable of selecting up to 32

different parameters.

9 PAR SELECT BIT 1

IN NO

10 PAR SELECT BIT 2

IN NO

11 PAR SELECT BIT 3

IN NO

12 PAR SELECT BIT 4

IN NO

13 BANK SELECT IN NO

When turned “ON” all output signals are turned OFF.

14 OUT COMMON OUT

Common Output signals

(

Bi-directional

)

15 REJECT(NG) OUT NO

Output when the fastening result is a REJECT. Indicates that the fastening operation

has fallen outside of the programmed fastening limits.

16 ACCEPT(OK) OUT NO

Output when the fastening results are an ACCEPT. Indicates the fastening operation

within the programmed fastening limits.

17 ABNORMAL OUT NO

Output when an Abnormal condition on the selected spindle

indicates that the spindle has detected an internal fault, and can no longer proceed.

18 READY OUT NO

Indicates the spindle

is ready to operate and inputs are enabled. This signal is inactive

(off) when the BUSY output is active (on).

19 BUSY OUT NO

Output after a START signal is received, and active until the fastening

complete and the READY signal is output.

20 PAR SELECT BIT 0

OUT NO

Output confirmation of PARAMETER SELECT 0~4 selections. Parameter Select bits

are active according to what parameter is set from the parameter select inputs.

21 PAR SELECT BIT 1

OUT NO

22 PAR SELECT BIT 2

OUT NO

23 PAR SELECT BIT 3

OUT NO

24 PAR SELECT BIT 4

OUT NO

25 DATA AVAILABLE OUT NO

Output when the fastening result data is available.

26 BYPASS OUT NO

Signal is active when the spindle is bypassed either from B

ypass input signal or from

the Controller’s bypass switch.

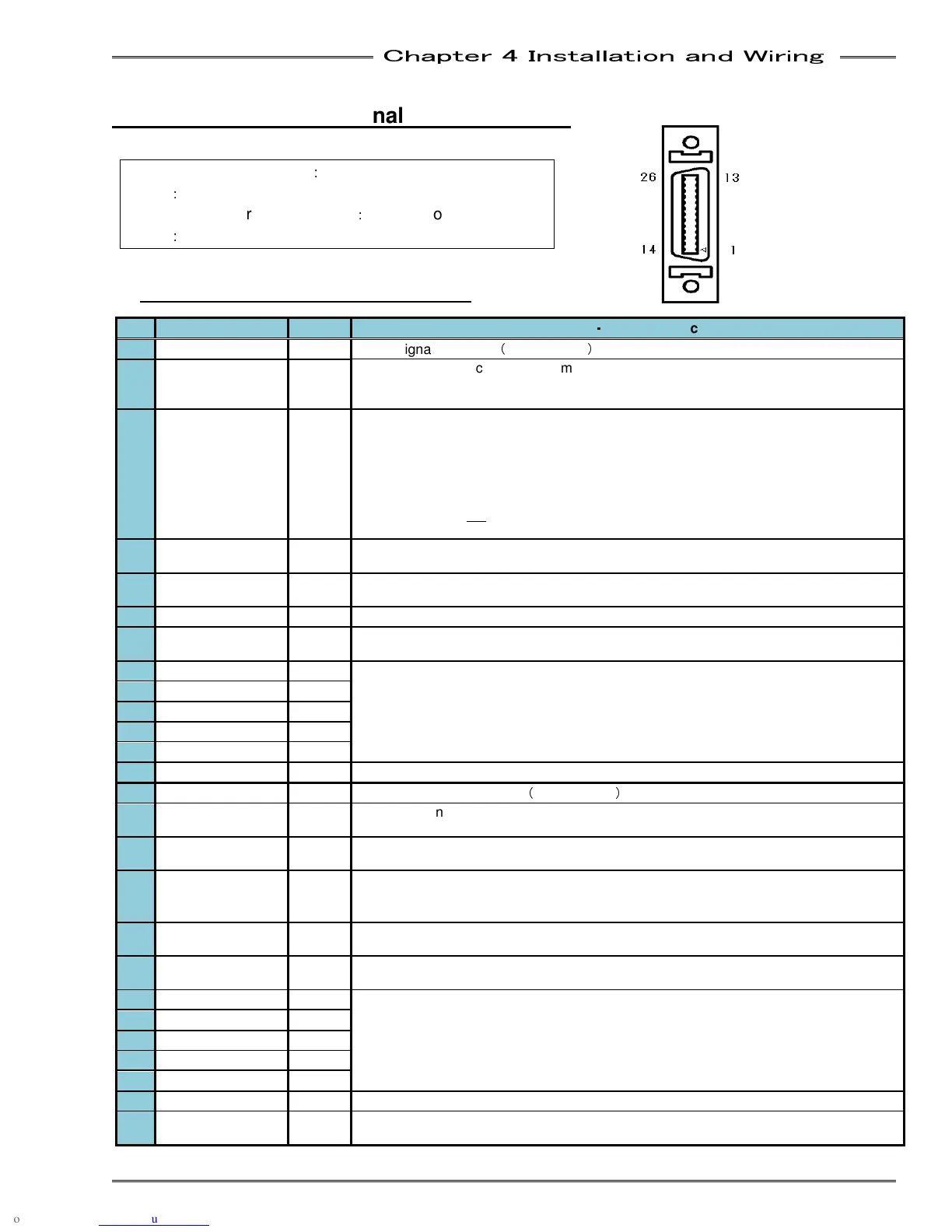

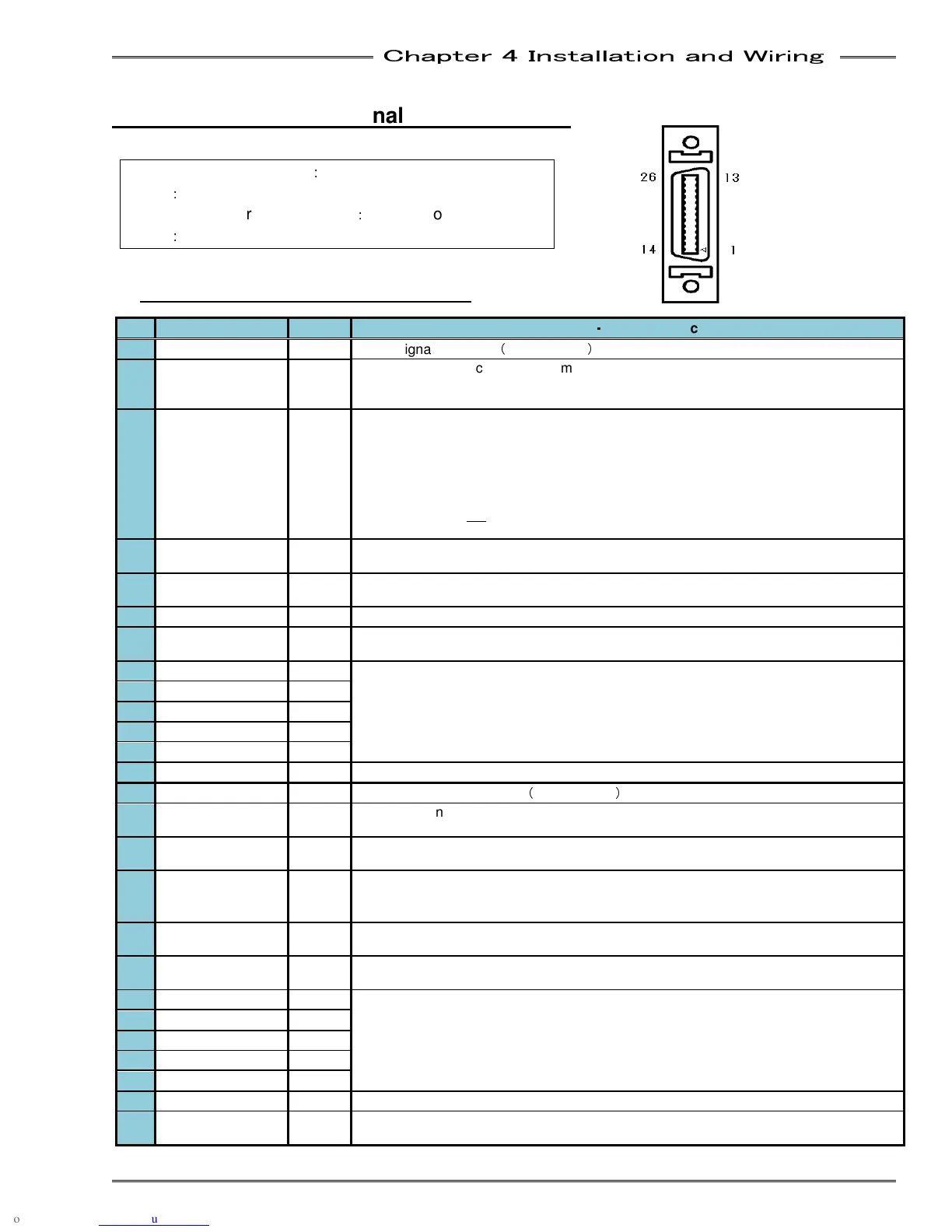

Connector on cable side

:

Sumitomo 3M Made

Type

:

10126-3000PE

Connector cover on cable side

:

Sumitomo 3M Made

Type

:

10326-52A0-008(26 position)

Loading...

Loading...