Chapter 3 System Description

PAGE 3-14

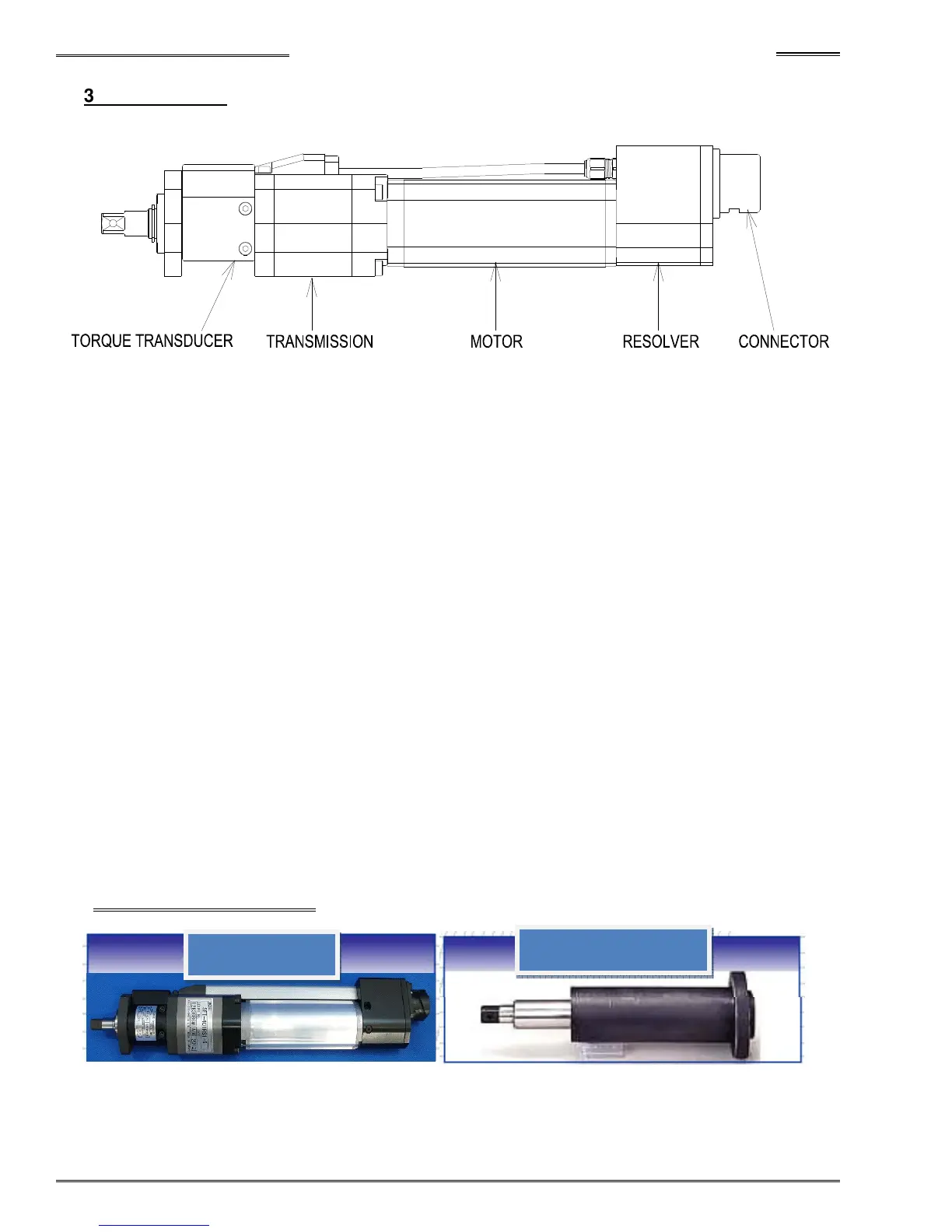

3-2-7 Tool Unit

Resolver

o Provides feedback for speed regulation to Servo Motor.

o Provides angular rotation monitoring capability to fastening operation.

High Speed Motor

o Totally enclosed DC permanent magnet motor.

o RS1, RS2 & RS3 for torque ranges up to 200nm.

Transmission

o Durable compact planetary gear transmission.

o Optional overshoot damper for high speed seating operations.

Torque Transducer

o Highly accurate strain gauge transducer.

o Very durable, compact design minimizes space requirements.

Preamp (built into the torque transducer)

o Intelligent transducer design accomplished through the use of an “ID Chip”.

o “ID Chip” used to verify integrity of fastening operations.

Connector

o Single connection point for Motor, Resolver and Transducer.

o Compact quarter-turn connector design.

Tool and Spindle Assembly

Spindle Assemblies are used to take up the travel of a threaded fastener as the fastener is rundown (so

the fastener does not run out of the socket or bit). Standard compression is 2.0 inches of travel. (See

section 2-2-3 for more information)

Straight Type

Straight TypeStraight Type

Straight Type

Spindle A

Spindle ASpindle A

Spindle Assembly

ssemblyssembly

ssembly

Loading...

Loading...