Chapter 4 Installation and Wiring

PAGE 4-16

4-2-3 Spindle Assemblies

Standard spindle assemblies mount inline with either a Straight Type or Offset Type tool. They are used

to “follow” the fastener as it is rundown so the fastener does not run out of the socket or bit tooling. They

are mounted to the tool mounting plate using screws. One screw thread has been provided to support

the tool during assembly/disassembly to prevent the tool from falling down when an installation screw is

fastened or loosened.

【

【【

【Caution regarding Spindle Assemblies

】

】】

】

- Select an adequate spindle assembly for the tools maximum torque.

- When installing the supporting screw, ensure that the screw does not go beyond the

thickness of the tool flange. It may cause the transducer to become less sensitive or

operate incorrectly.

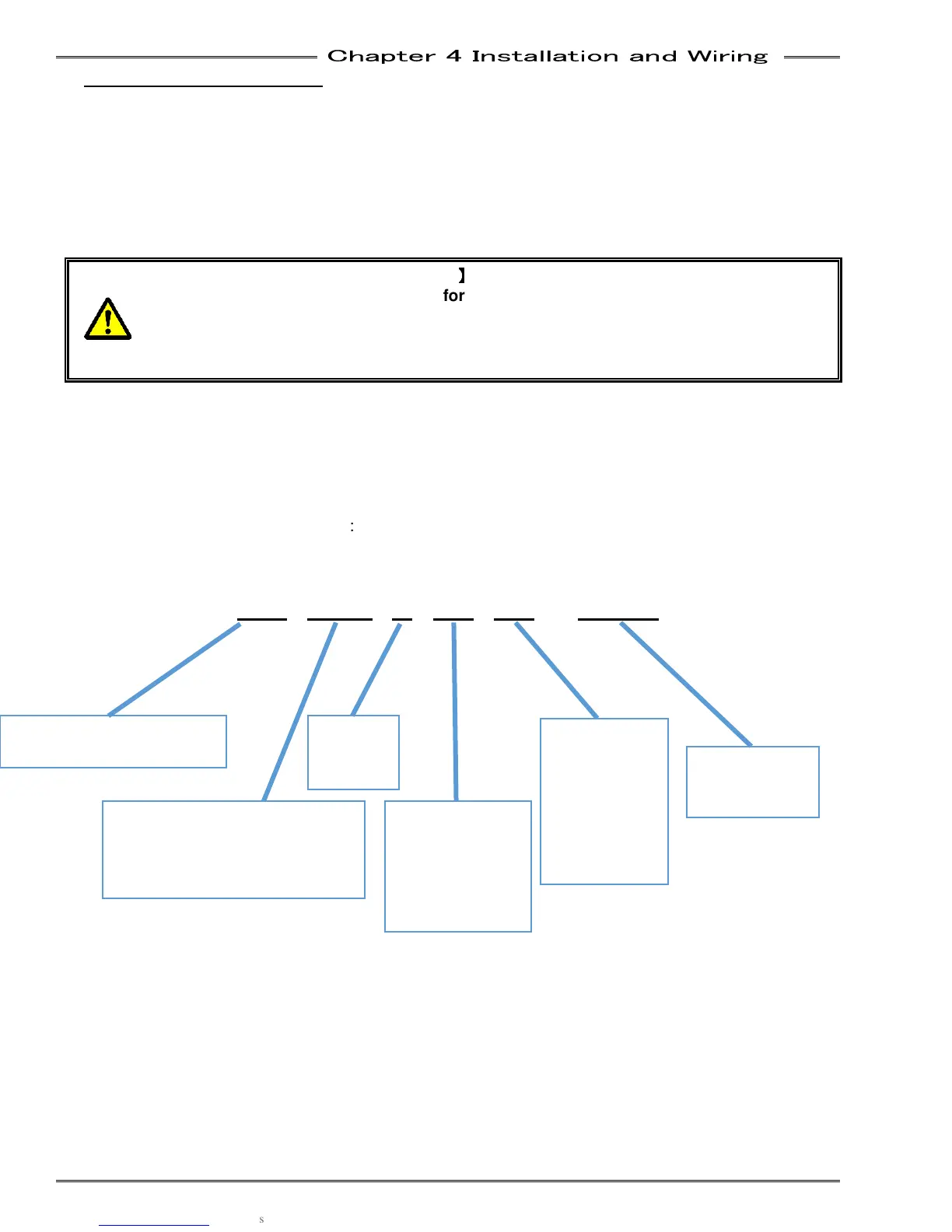

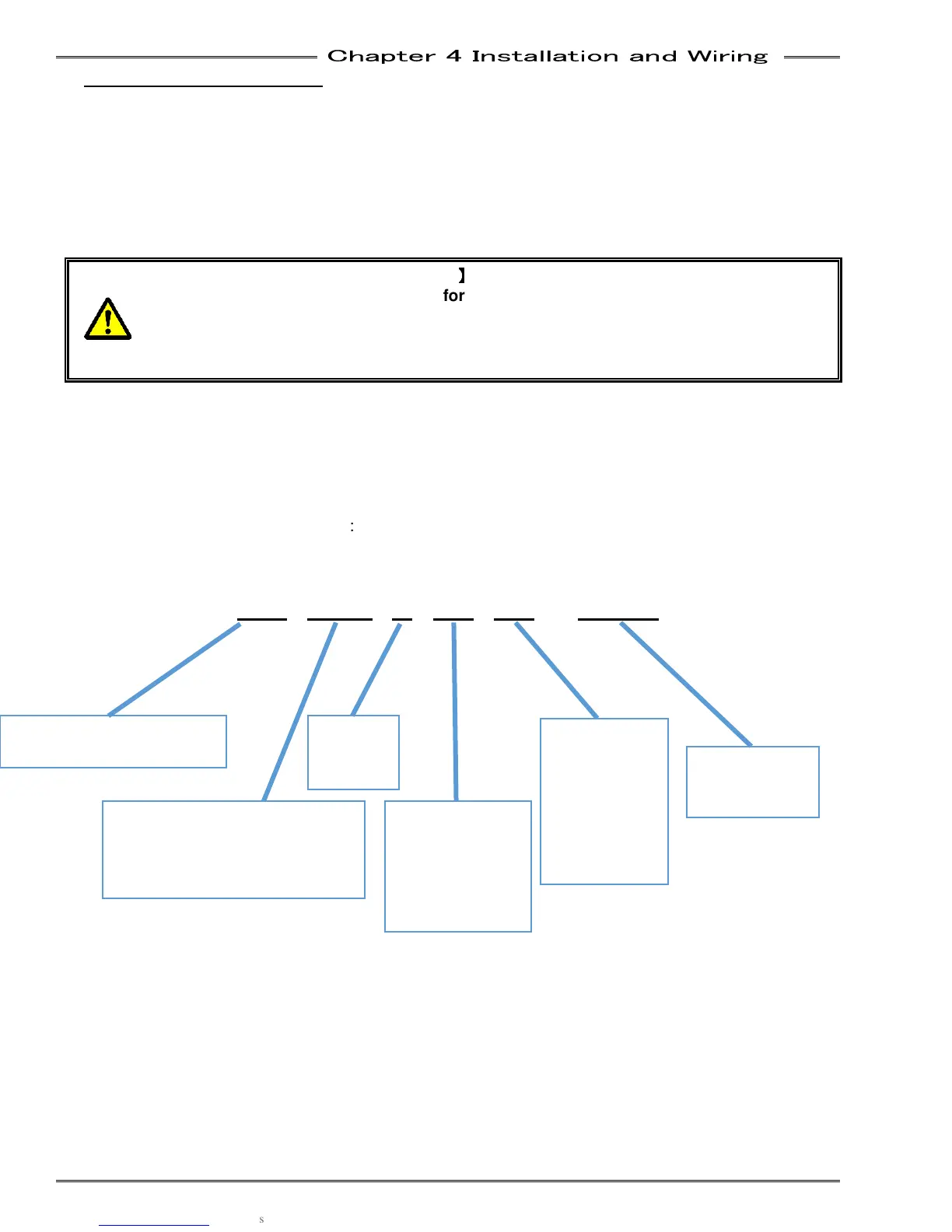

Spindle Assembly numbering convention:

SA

SASA

SA-

--

-3S1

3S13S1

3S1-

--

-2

22

2-

--

-38

3838

38-

--

-38

3838

38

x

x x

x X.XX

X.XXX.XX

X.XX

OA = OFFSET SPINDLE

LEADING “3” = 3000 SERIES

S1, S2 & S3 = NUTRUNNER MOTOR

SIZE (SEE TOOL ASSEMBLY)

FEMALE INPUT

SQUARE DRIVE

38 = 3/8

50 = 1/2

62 = 5/8

75 = 3/4

SPINDLE

STROKE

(In)

MALE OUTPUT

SQUARE

DRIVE

38 = 3/8

50 = 1/2

62 = 5/8

75 = 3/4

IF SPINDLE IS

LONGER THAN

STANDARD

Loading...

Loading...