Chapter 4 Installation and Wiring

PAGE 4-25

4-5 Tool Wiring and Installation

4-5-1 Tool Installation Procedures

Avoid mechanical contact on the TOOL Unit main body.

_ Contact between tools.

_ Jammed or pinched cables.

_ Improper installing position (methods).

Secure the tool on the tool installation plate with a bolt.

Mechanical contact may cause unstable t

orque accuracy, it may cause mechanical

damage such as bolt fracture.

The tool must be mounted from the front mounting bolt pattern for proper operation.

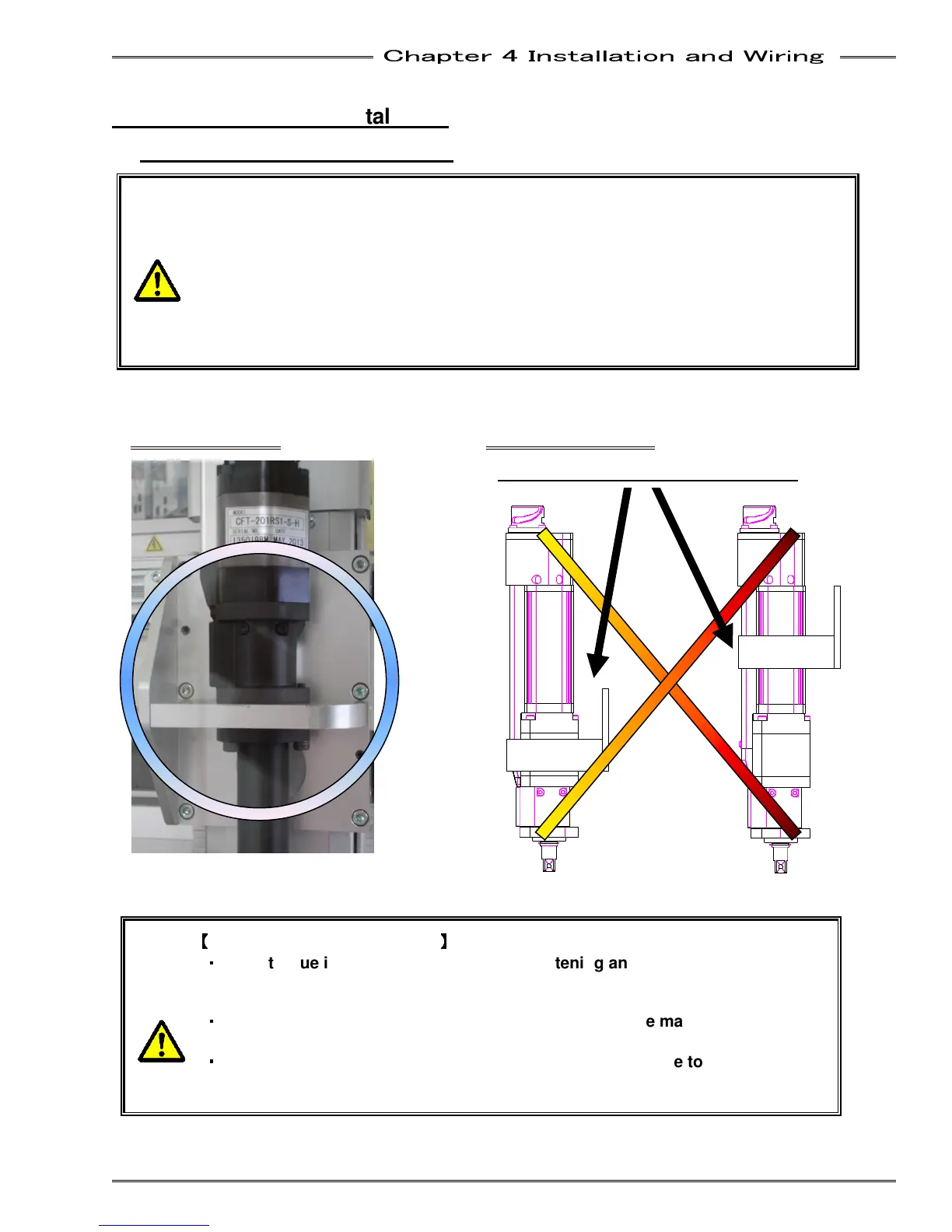

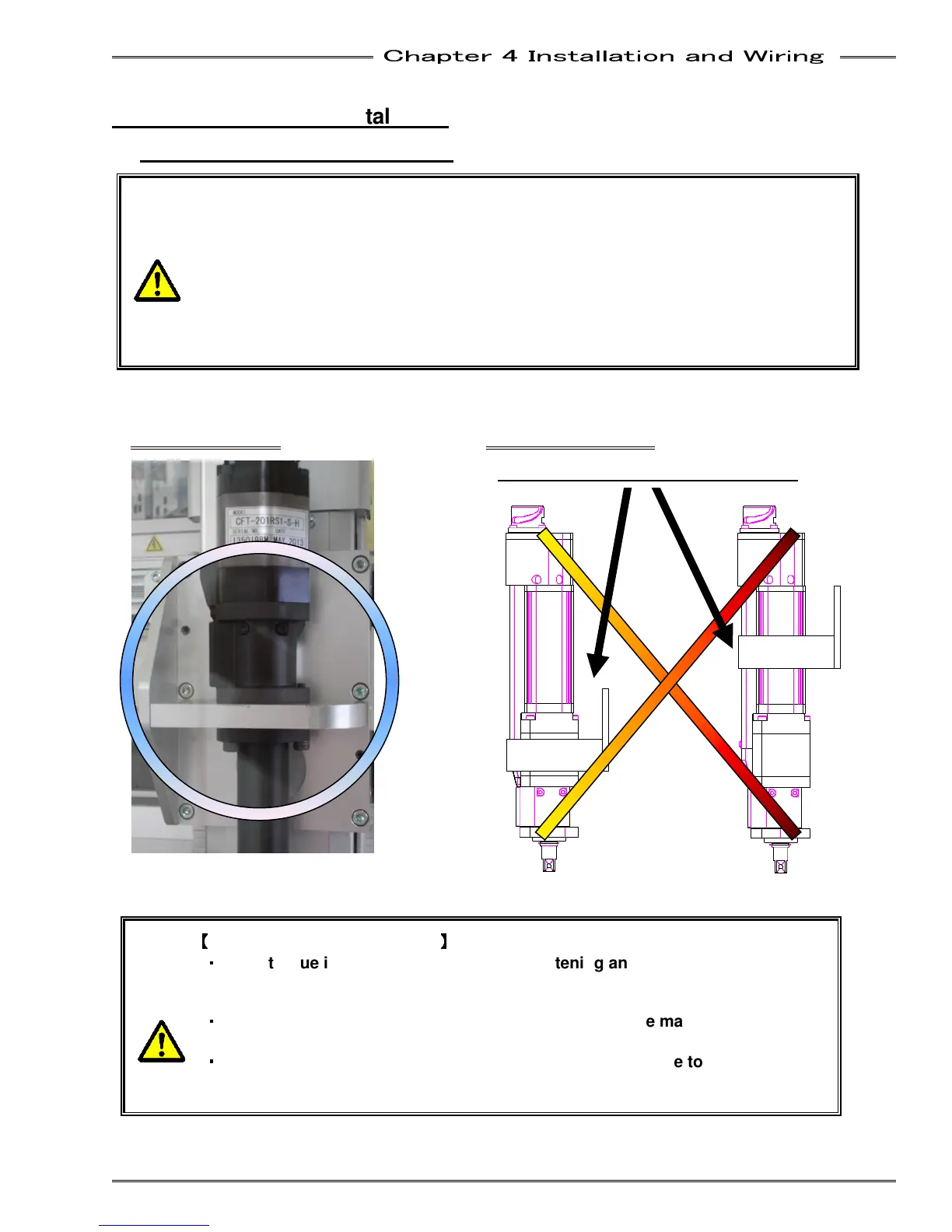

Proper Installation Improper Installation

【

【【

【

Caution regarding installation

】

】】

】

・

・・

・

Large torque is applied when the tool is fastening and the same amount of

torque is applied to the tool connection parts. Therefore, the tool should be fixed

on the proper locations and the specified mounting screws should be used.

・

・・

・

Do NOT apply strong shock or force to a tool or damage may occur (Due to

sensitive parts)

・

・・

・

Use cylinder cushions or shock absorbers to decelerate the tool head motions

and prevent excessive vibration, especially in short cycle time applications

operating at high speeds. Repeated shock (overtime) could damage a tool.

Tool Mounting cannot be fixed to main body

Loading...

Loading...