Chapter 7 Fastening Instructions

PAGE 7-2

7-1

Fastening Settings Outline

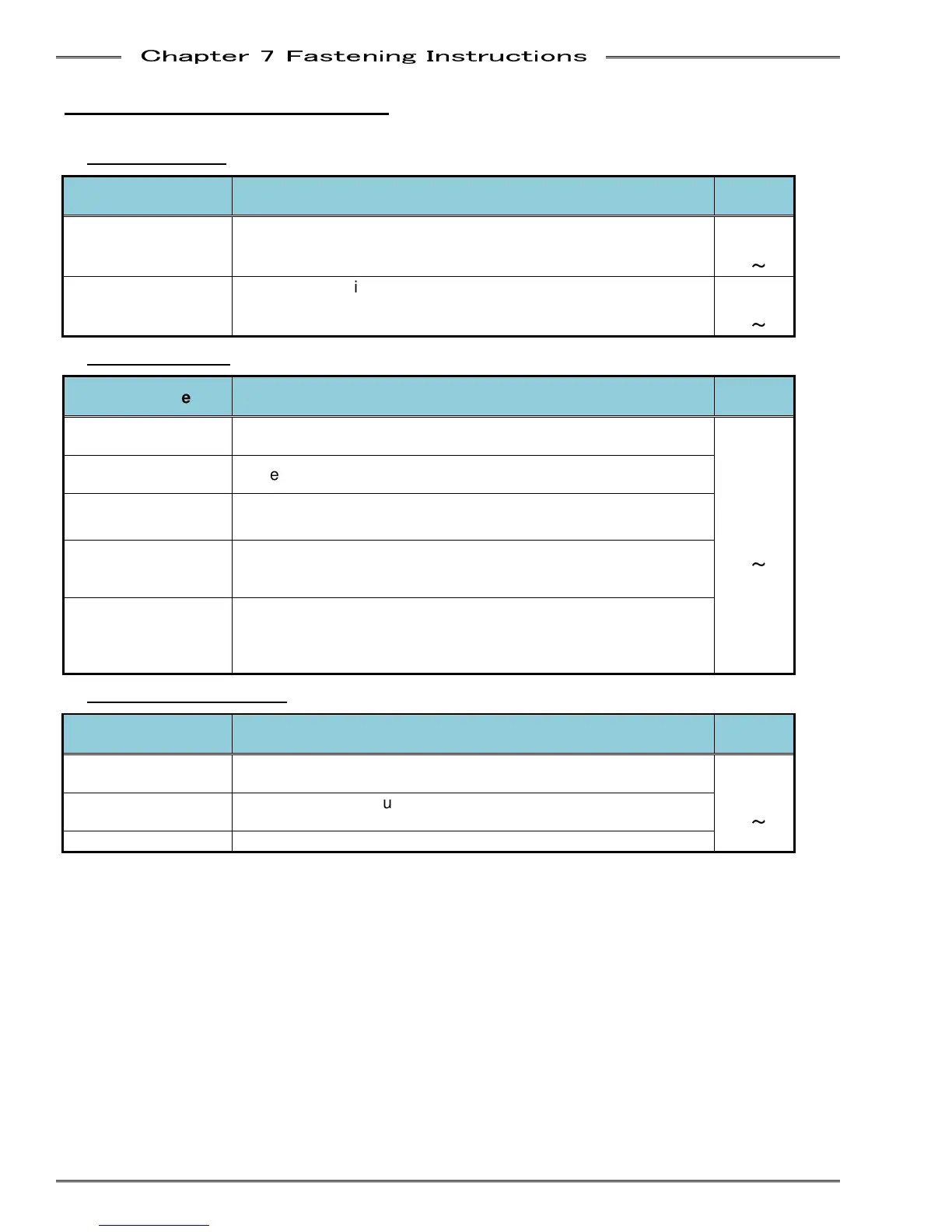

● Fastening Method

Fastening Method

page

Torque Control

Fasten until attaining the torque value set as the standard torque

Check torque, angle, time and rate

Up to 3 step fastening can be performed

PAGE

3

~

Angle Control

Fasten until attaining the angle value set as the standard angle

Check torque, angle, time and rate

Up to 3 step fastening can be performed

PAGE

10

~

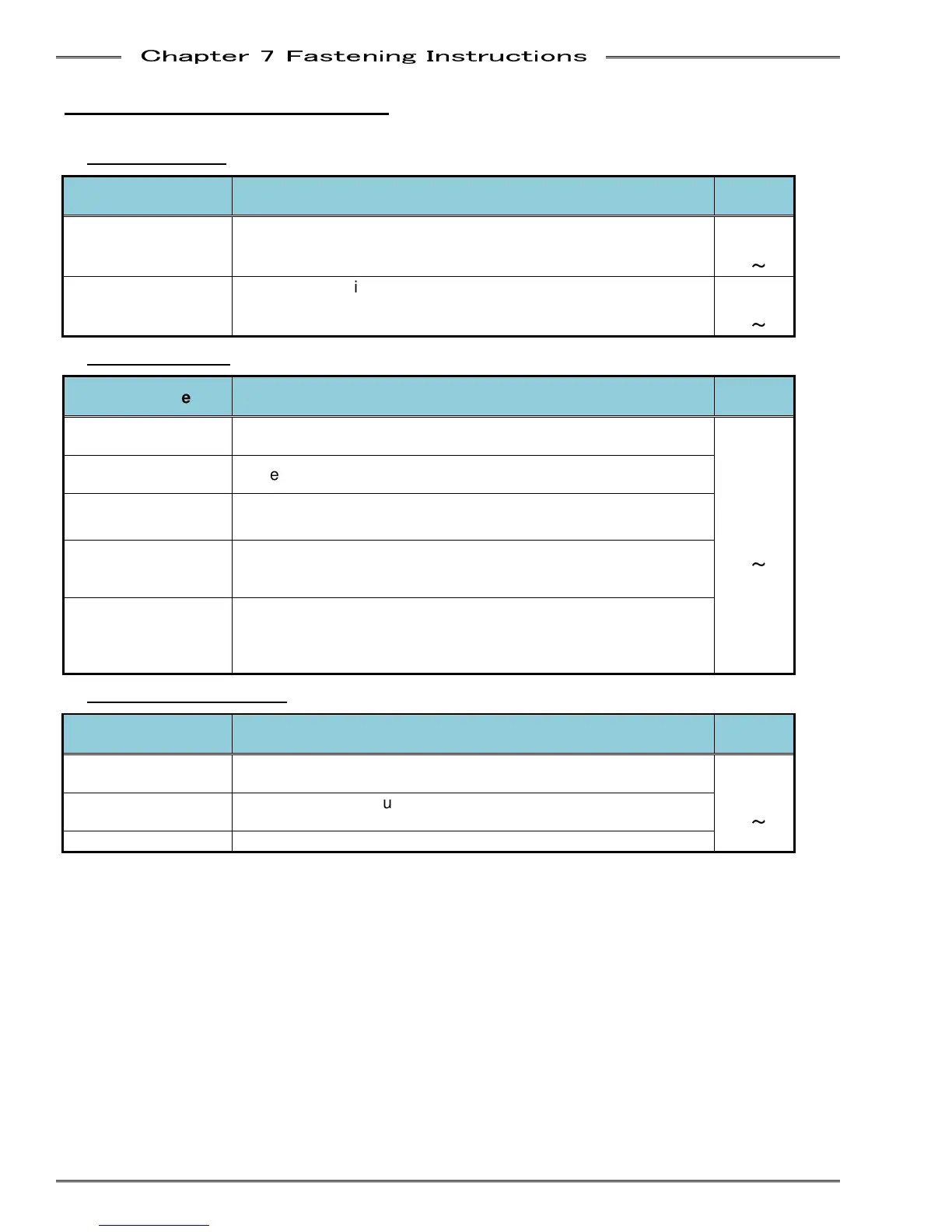

● Fastening Options

Fastening Item

page

Reverse Operation

before fastening

Reverse operation is performed for the number of revolutions

specified before fastening starts.

PAGE

17

~

Fastening in a CCW

direction

Fasten in a counter- clockwise direction (left-hand thread)

Torque Hold between

steps

¼ of the torque value is maintained while the fastening operation

stops between steps (1

st

step & 2

nd

step)

Save Curve Disable

The fastening curve will not be saved in the controller if this is

enabled (REJECT/ABNORMAL curves will be saved regardless

of this setting)

Disable Angle count

below Snug Torque

When enabled, the angle measurement is stopped if the torque

drops below SNUG Torque any time during fastening. (When

disabled, after the Snug torque is reached, angle measurement

will continue regardless of torque value)

● Operation After Fastening

Fastening Item

page

1 Pulse Reverse

The reverse rotation is used to prevent the socket from sticking

or locking after fastening.

PAGE

20

~

Torque Recovery

Once Standard Torque is attained, it is maintained for the preset

time (holding at standard torque for the preset time)

Servo Lock The current resolver value is held after fastening ends.

Loading...

Loading...