Chapter 7 Fastening Instructions

PAGE 7-31

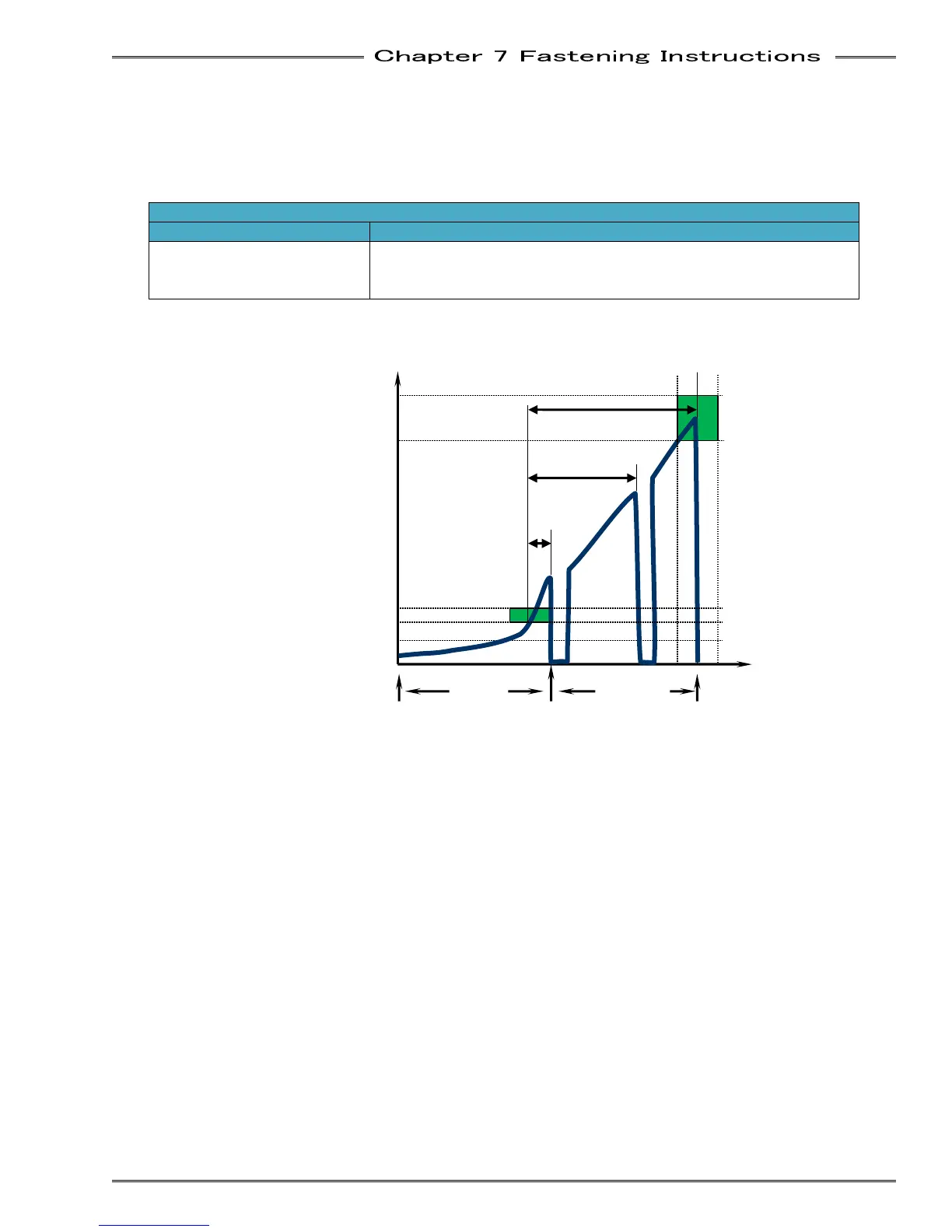

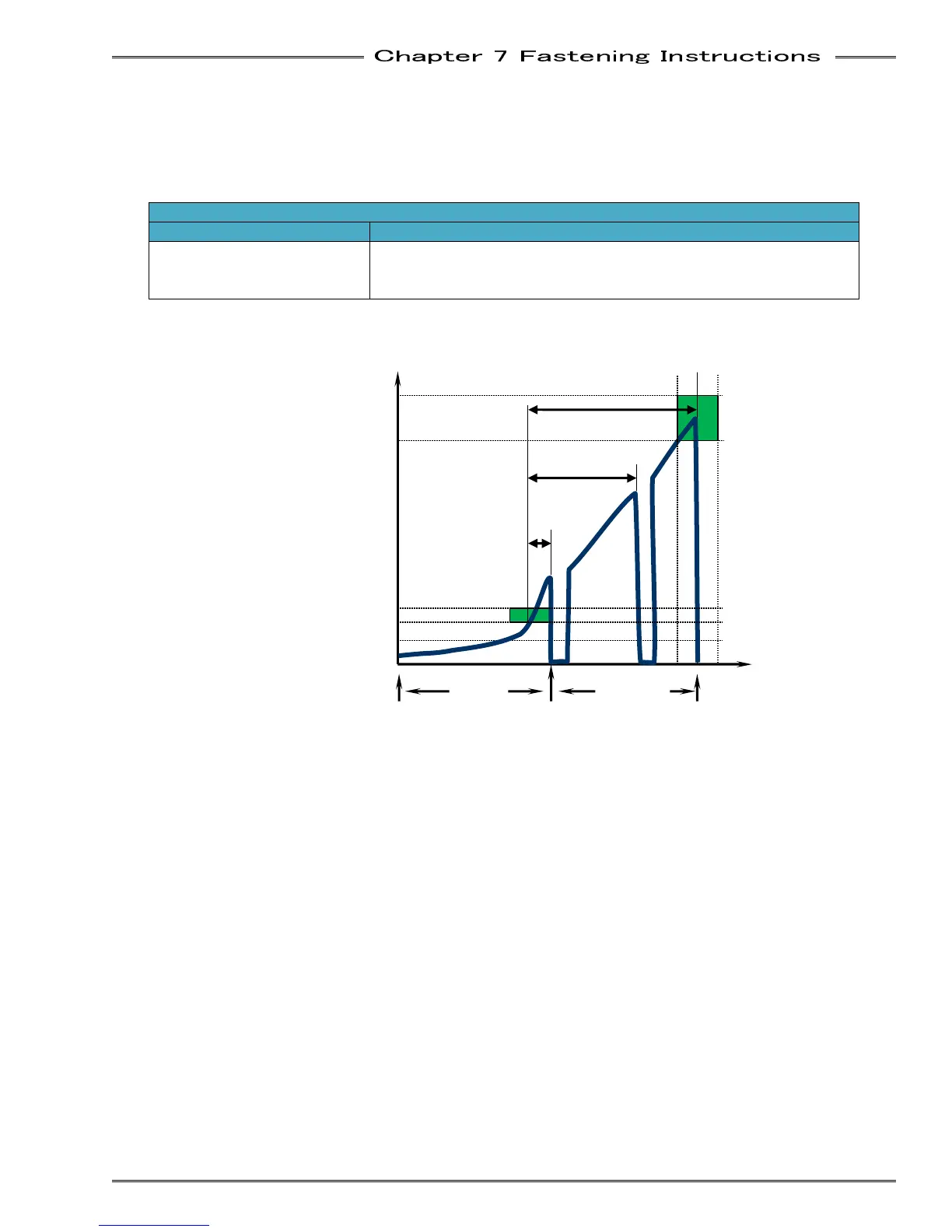

<SNUG Torque Check>

P

Because Final Angle is measured from the point where the desired SNUG TORQUE is reached, it

may be critical in certain applications to monitor this torque. This is especially true for Angle Control

operations, where overshooting of the SNUG TORQUE could effect the Final Torque values.

SNUG TORQUE HIGH LIMIT

Reduced joint compression.

Increased joint friction.

Incorrect parameter set-up.

<Rundown Revolution Check>

Rundown Revolution High and Low Limits can be set to identify fasteners that may be too long or too

short for normal operations or for a redundant check for bolts that reach torque but are not seated. This

is especially the case where different length fasteners are used and placed by hand. The number of

rundown revolutions until fastening end is monitored and judged. Rundown Revolutions is measured

from the start of revolution to fastening end. This can be used in conjunction with the Low 1st Time Limit.

Note: Since fastener engagement is not always 100% guaranteed (and this is counted as revolution),

bolt length differences must be enough for detection without setting limits too tight or problematic rejects

may occur. Also, if bolts are hand started (with a variable starting point) this function is not recommended

unless the bolts are pre-started to the same point every cycle.

Torque

Angle/Time

1

st

Time

2

nd

Time

Standard Angle

Ramp Down Start Torque

1

st

Angle

2

nd

Angle

Snug Torque

Snug Torque High Limit

Loading...

Loading...