Chapter 7 Fastening Instructions

PAGE 7-20

•

Fastener Slip Check

This selection enables fastener slip detection during the fastening process.

(Example: A fastener with a nut on opposite side starts to rotate or ‘slip’ while torque

is being applied)

Once the torque reaches Snug Torque, the system monitors the torque drop from

peak torque and starts to count angle if the torque drop value is more than D-No.121

[Fastener Slip Torque]. If torque does not recover within D-No.215 [Fastener Slip

Angle], the fastening is aborted and reported as Fastener Slip Reject.

The system outputs Rate 1 Low Reject, Rate 2 Low Reject, and Rate 3 Low Reject

signals together (PLC output signals) for this reject condition.

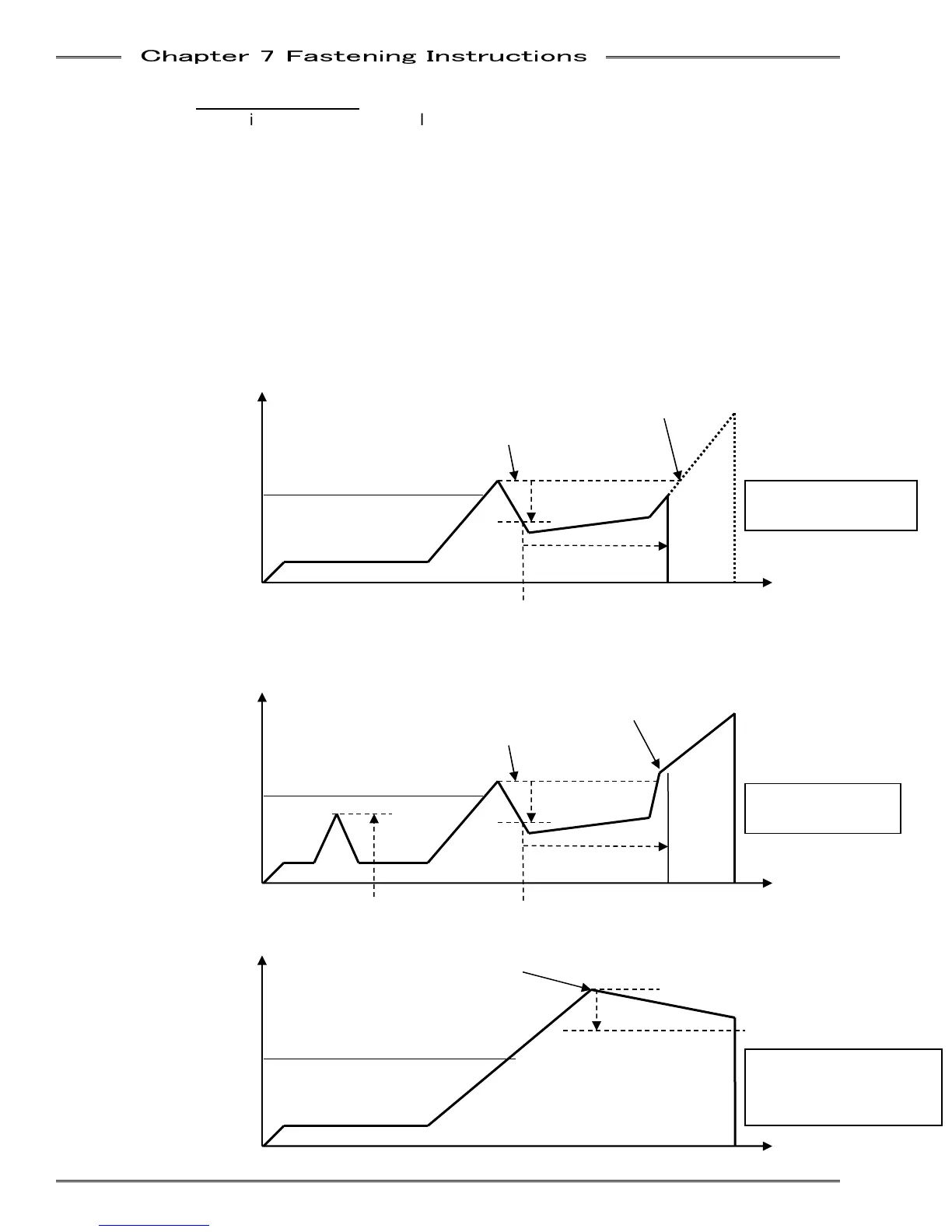

o Example of Fastener Slip detection

Snug Torque = 30Nm, Fastener Slip Torque = 10Nm, Fastener Slip Angle = 50 Degree

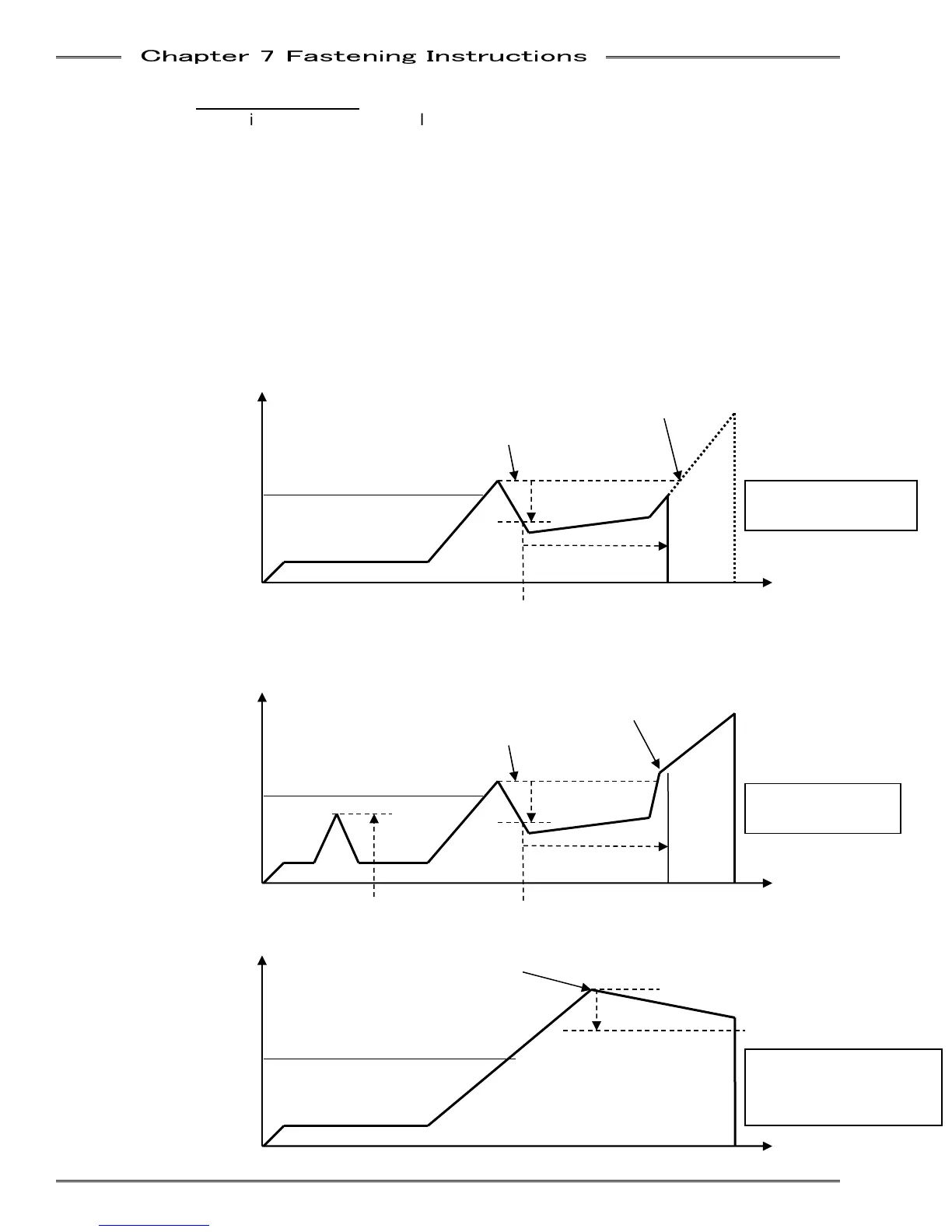

o Example of Fastener Slip not detected

Torque

Snug

30Nm

Angle

Slip Start Point

D-No.215 50 Deg.

Fastener Slip Reject

Standard Torque

Peak Torque of fastening

Torque recover point

Torque

Snug

30Nm

Angle

Slip Start Point

D-No.215 50 Deg.

Torque recovered

within (50deg) limit.

Standard Torque

Peak Torque of fastening

Torque recover point

Torque

Snug

30Nm

Angle

Not enough torque drop to

be detected as fastener

slip.

Standard Angle

Peak Torque of fastening

Ignore below Snug Torque

Torque not recovered

within (50deg) limit.

Loading...

Loading...